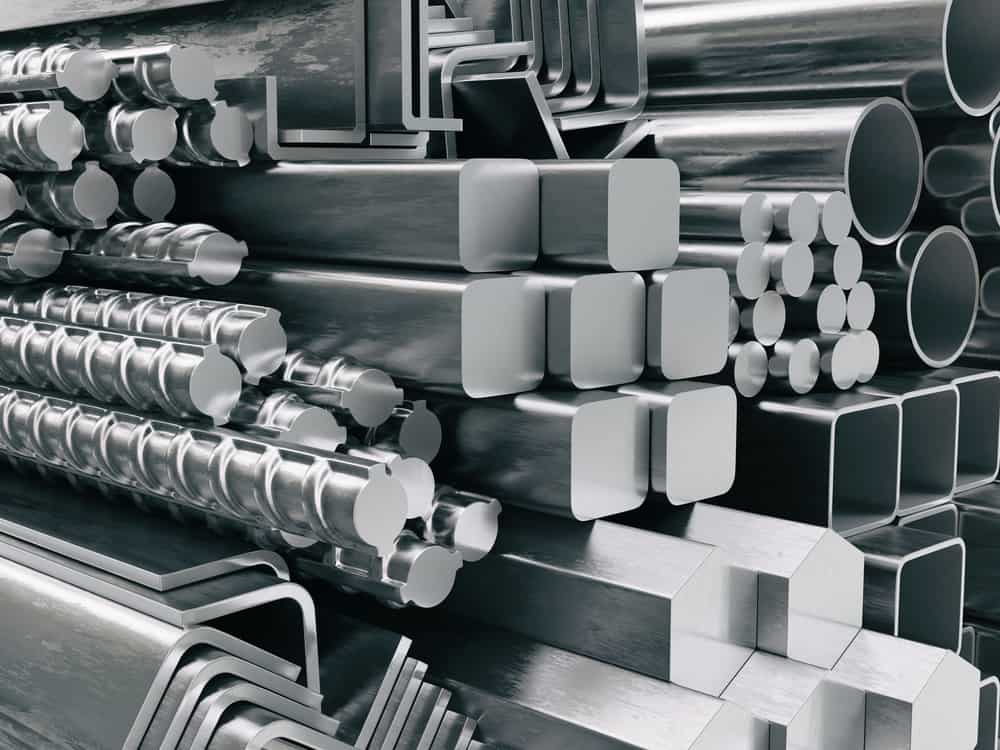

EN 1.4301 Stainless Steel (X5CrNi18-10)

DIN EN 1.4301 stainless steel (X5CrNi18-10) is a conventional austenitic stainless steel with good resistance to atmospheric, organic and inorganic chemicals. This material is widely used due to its excellent resistance to intergranular corrosion, good cold deformability, good deep drawability and weldability.

1.4306 (X2CrNi19-11) and 1.4307 (X2CrNi18-9) are ultra-low carbon versions of 1.4301. The aim is to improve corrosion resistance after welding and prevent carbide precipitation caused by long-term stress relief.

DIN 1.4301 Magnetic

EN X5CrNi18-10 is not magnetic in the annealed state, but may become slightly magnetic due to the addition of martensite or ferrite during cold working or welding.

X5CrNi18-10 Technical sheet

The following tables and lists provide the SS 1.4301 data sheet, including chemical composition, physical properties and mechanical properties, etc.

DIN EN 1.4301 Chemical Composition

The following table shows the chemical composition of material 1.4301 based on casting analysis.

| Chemical composition, % | ||||||||||

| Country (Region) | Standard | Steel grade (material number) | C, ≤ | Yes, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | No | N, ≤ |

| European Union | EN 10088-2 | X5CrNi18-10 (1.4301) | 0.07 | 1.00 | 2:00 | 0.045 | 0.015 | 17.5-19.5 | 8.0-10.5 | 0.10 |

| EN 10088-3 | 0.07 | 1.00 | 2:00 | 0.045 | 0.030 | 17.5-19.5 | 8.0-10.5 | 0.10 | ||

Grades:

- EN 10088-2: Technical conditions for delivery of corrosion-resistant stainless steel sheets/plates and strips for general use ; Specific ranges of sulfur content can provide improvement of specific properties. For machinability, a controlled sulfur content of 0.015% to 0.030% is recommended and permitted. For weldability, a controlled sulfur content of 0.008% to 0.015% is recommended and permitted. For polishability, a controlled sulfur content of 0.015% maximum is recommended.

- EN 10088-3: Technical conditions for delivery of semi-finished stainless steel products, bars, rebars, wires, profiles and bright corrosion-resistant steel products for general use.

Mechanical properties of material X5CrNi18-10

The following table provides the mechanical properties of SS 1.4301 in solution annealed condition for steel sheets, steel plates and steel strips.

| Standard | Steel Name (Steel Number) | Product condition | Thickness (mm), ≤ | 0.2% proof strength (Mpa), (transverse) | 1% proof strength (Mpa), (transverse) | Tensile strength (MPa) | Elongation (%), <3mm thick | % elongation, ≥ 4 mm thick | Impact energy (J) KV2 > 10mm thick (longitudinal) |

Impact energy (J) KV2 > 10mm thick (transverse) |

| EN 10088-2 | X5CrNi18-10 (1.4301) | cold rolled strip | 8 | ≥230 | ≥260 | 540-750 | ≥45 | ≥45 | – | – |

| hot rolled strip | 13.5 | ≥210 | ≥250 | 520-720 | 100 | 60 | ||||

| hot rolled board | 75 | ≥210 | ≥250 | 520-720 | 100 | 60 |

The following tables show the mechanical properties of solution annealed X5CrNi18-10 under conditions 1C, 1E, 1D, 1X, 1G and 2D.

| Mechanical properties (solution annealed) | ||||||||

| Standard | Steel grade (steel number) | Diameter (d) or Thickness | ||||||