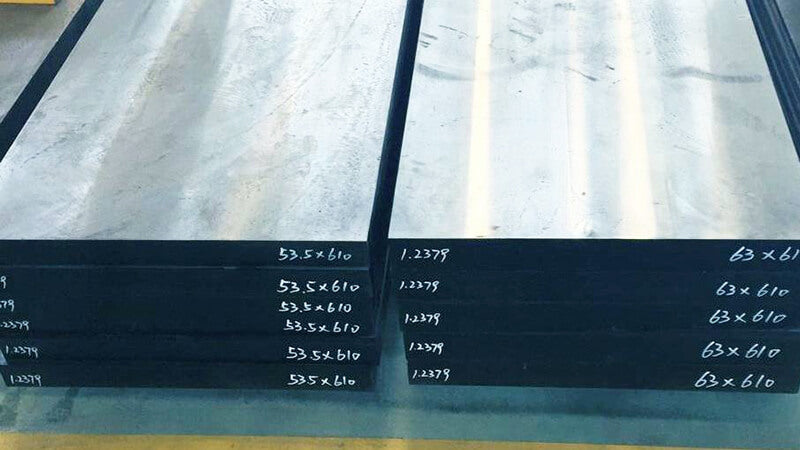

DIN EN 1.2379 Steel (Material X153CrMoV12)

DIN 1.2379 steel (material X153CrMoV12) is a high carbon, chromium, molybdenum, vanadium cold worked tool steel with high wear resistance, good dimensional stability, toughness and hardenability. Due to the secondary hardening properties, it is easy to perform supplemental nitriding and surface coating. High chromium increases wear resistance and toughness and contributes to corrosion resistance; Vanadium gives the steel a finer grain structure and prevents excessive grain growth and improves the hardenability of the steel; Molybdenum increases heat resistance and hardenability, improves corrosion and wear resistance.

Material Data Sheet 1.2379

The following content provides the 1.2379 data sheet, including chemical composition, mechanical properties and physical properties.

Chemical composition

Datasheet -1, Chemical composition (melt analysis) for cold work tool alloy steels.

| Chemical composition, % | |||||||

| Standard | Steel grade (steel number) | W | Yes | Mn | Cr | Mo | V |

| EN ISO 4957 | X153CrMoV12 (1.2379) | 1.45-1.60 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | 0.70-1.00 | 0.70-1.00 |

DIN 1.2379 properties

The datasheet below summarizes 1.2379 properties, including physical properties and mechanical properties.

Physical properties

Datasheet -2, Physical Properties of X153CrMoV12

| Density, g/cm3 | 7.7 |

| Specific heat capacity, J/(Kg·K) | 460 to 20 ℃ |

| Electrical resistivity, μΩ·m | 0.65 (20℃) |

| Elastic modulus, GPa (kN/mm2) | 210 |

| Thermal conductivity, (W/m·K) | 16.7 (20℃) |

| 20.5 (350℃) | |

| 24.2 (700℃) | |

| Coefficient of thermal expansion, (10 -6 /K) | 10.5 (20-100℃) |

| 11.5 (20-200℃) | |

| 11.9 (20-300℃) | |

| 13.0 (20-400℃) |

Mechanical properties

Datasheet -3, The table below shows 1.2379 mechanical properties including tensile strength and yield strength.

| Mechanical properties | ||||

| Country (Region) | Standard | Steel grade (steel number) | Tensile strength, MPa, ≥ | Yield strength, MPa, ≥ |

| European Union | EN ISO 4957 | X153CrMoV12 (1.2379) | 860 | 420 |

1 MPa = 1 N/mm2

Heat Treatment and Hardness

Soft annealing: 800°C – 850°C (1470°F – 1560°F), oven cooling, maximum Brinell hardness 255 HB.

DIN 1.2379 Hardening: austenitizing temperature 1020 ± 10 °C; Quenching agent: air; Tempering temperature: 180 ± 10 °C; Minimum Rockwell hardness: 61 HRC.

Datasheet -4, Hardness Quenching Temperature

| Hardness Quenching Temperature | |

| Quenching temperature, °C | Hardness, HRC |

| 100 | 64 |

| 200 | 62 |

| 300 | 60 |

| 400 | 59 |

| 500 | 60 |

| 550 | 58 |

| 600 | 50 |

Isothermal transformation diagram

The image below shows the Isothermal Transformation Diagram of 1.2379 steel (also known as Time and Temperature Transformation, TTT) for reference.

1.2379 Use of materials

Use of 1.2379 tool steel, including: thread and die rolling, fracture sensitive cutting, sinking and printing cups, fryers, reamers, sockets, shear knives, space needles, machine knives, cutting tools, etc.

Equivalent steel grades DIN 1.2379

Material data sheet DIN EN 1.2379 -5, European standard (including German DIN, British BSI, French NF and other EU member state standards) Steel X153CrMoV12, steel 1.2379 equivalent to Chinese GB standard, ASTM AISI and US SAE, Japanese JIS standard and ISO standard, etc

Notes: The old material designation of X153CrMoV12 is X155CrVMo12-1 in DIN 17350: 1980.

| EN X153CrMoV12, 1.2379 equivalent material | |||||||||||

| European Union | Germany | USA | ISO | China | Japan | ||||||

| Standard | Steel Name (Material Number) | Company | Steel Name | Standard | Note (UNS) | Standard | Note | Standard | Note | Standard | Note |

| EN ISO 4957 | X153CrMoV12 (1.2379) | Bohler | Bohler K110 | AISI; ASTM A681 | D2 (UNS T30402) | ISO 4957 | X153CrMoV12 | GB/T 1299 | Cr12Mo1V1 | JIS G4404 | SKD10, SKD11 |

1comment

Dear sirs

We have inquire for steel din 1.2379 standart tube fales semless 4 meter or beam if u cant make it

Please reply us gor more detail target 50 ton yearly

Best regards

Hovik