Testing of the concrete mix must be performed to ensure it conforms to the supplier's product specifications and meets code requirements.

What is mixture?

An admixture is an additive added to concrete during production or after mixing to improve the properties of the concrete.

The following main features can be highlighted.

- Reduce water content and increase workability

- Reduce cement content

- Delay setup time

- Attack hardening, initial strength gain, etc.

Nowadays there seems to be no concrete made without additives. The type of additive is selected depending on the project requirements.

The article Flow Agent You can read (Important Factors to Know) for more information about modern additive types.

For more information, see the article Concrete additives – Types and functions.

Additive testing can be done in two steps.

- Test supplement

- Concrete Test

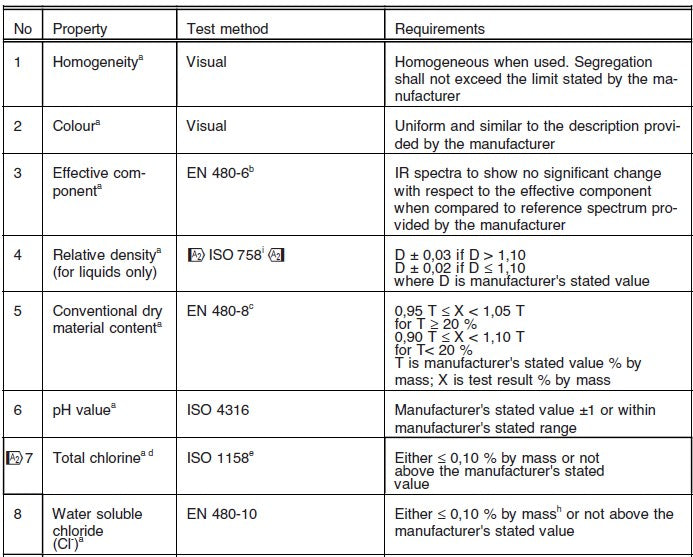

Additive testing must be performed prior to use in accordance with project specifications or supplier information. Some of the conditions can be assessed based on supplier specifications in accordance with BS EN 934-2-2001.

Some of these tests are relative density, pH, etc.

However, other parameters of the additive must comply with regulations.

The following tables from BS EN 934 provide limits for test results for various types of additives.

General requirements

Water reducing additives

Water retention additives

Accelerator additives

Set retardant additives

The requirements for each type of additive are correspondingly high.

All information on additive testing can be found in the EN 934 – 2 – 2001 standard.

The following substances in additives are generally tested under general requirements:

- relative density

- PH value

- Total alkali content

- Dry material content

- Water-soluble chloride content

- Initial setup time

- Final setup time

As most manufacturers note, determining how much additive to use for best performance is a process of trial and error.

However, manufacturers usually specify the area of the column to be used for mixing concrete. It is usually given in letters per 100 kg of cement.