How can corrosion be prevented? What practical methods can be used and what alternatives are there? Let's discuss this topic in detail, as it is very important to know when dealing with steel construction.

First, let's see what the consequences of steel corrosion are.

As soon as we expose steel for the first time to a corrosive environment, the decomposition process begins. At first it is a very slow process and we only realize it when it reaches a certain point.

The first sign is that it starts to change color.

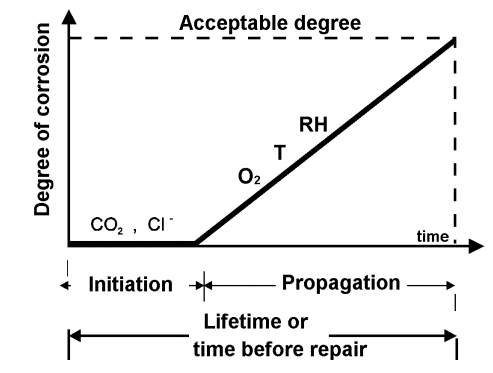

The following figure shows the simple descriptive life model for rebar. The same could be used for other steels.

Where T is temperature and RH is relative humidity

Where T is temperature and RH is relative humidity

- Introduction

Initiation is the phase in which there is time for erection until the aggressive substance reaches the steel and passes away. The aggressive substance can be chloride or carbonate.

- Propagation

Propagation is the period from depassivation to reaching a certain acceptable level of deterioration of the structure.

Lifting time or repair time must be taken into consideration when working with steel, as they are extremely important and lack of attention can lead to serious problems and additional costs.

How can corrosion be prevented?

Let's discuss the available corrosion protection methods. Corrosion and rust prevention must be carried out as described above before repair.

So that we have a more efficient structure.

The risk of corrosion can be avoided or minimized through the following measures and use of materials.

- Types of metal

- Protective coatings

- Environmental measures

- Sacrificial coverings

- Corrosion inhibitors

- Design and detailing

- maintenance

Let's discuss each type that can be used to prevent corrosion.

Types of metal

If possible, it is advisable to use steel that is not susceptible to corrosion.

Metals such as aluminum and stainless steel could be used as alternative materials.

When selecting these alternatives, the cost factor and material resistance must be taken into consideration.

For example, when building a bridge, we cannot replace structural steel with aluminum or stainless steel. However, if we build a simple roof without larger gaps, we can use the aluminum frame to support the roof.

protective coating

There are basically two types of protective coatings that can be used to prevent rust.

They are

- painting

The paint serves as a protective barrier for the steel and prevents the steel from being exposed to the environment.

The application of color is a vast subject that requires detailed study. Let's talk about this briefly.

Depending on the type of structure and the location where it will be built, the specifications for painting are determined. For example, different specifications apply to offshore structures and structures built offshore.

Near the sea, the risk of corrosion is very high and requires greater protection. However, if the building is built in the center of the country, we do not need to make such restrictions when choosing the color.

Furthermore, an internal structure that is not excessively exposed to the environment does not require particularly stringent specifications to protect the steel.

The amount of coatings applied to steel is one of the crucial factors for protection. Therefore, the lower the risk, the fewer the number of coatings.

- Powder coating

Powder coating is a type of membrane created on the surface of steel. When applying powder coating, the following steps are followed.

-

- Clean the metal surface

- Apply dry powder

- The metal is heated and the powder melts, forming a smooth, continuous film.

- Different powder compositions can be used.

- Composition may include acrylic, polyester, epoxy, nylon and urethane

Environmental measures

It is the most suitable and sustainable method to protect steel. However, we cannot always protect the structure with this method.

We must have experience with its use in construction and service.

In general, internal elements are less susceptible to corrosion due to the absence of corrosive substances.

With adequate coverage, the simultaneous presence of moisture and oxygen is minimal.

For example, if we build a building near the sea, we can reduce corrosion by minimizing or preventing sea breezes from entering the building.

Sacrificial coverings

The name itself gives an idea of the coating. It is a type of metallic coating applied to steel. It can usually be in the form of oxides.

There are two methods for applying sacrificial coatings

- Cathodic protection

Although we are not familiar with the name, this is the well-known plating method. The steel is coated with zinc. Furthermore, zinc is more active than steel and supports the process quite easily.

This method is widely used around the world as it is more reliable and durable.

The articles Hot Dip Galvanizing AND Galvanizing vs. painting discuss galvanizing to protect the steel from corrosion.

Rows of steel piles, structural steel, offshore structures, ship hulls, etc. are protected from rust by this process.

- Anodic protection

Applying a less active metal, such as tin, to the steel alloy serves as anodic protection.

As tin is not a corrosive material, the steel is protected until the layer of tin applied is on the surface of the steel.

Anodic protection is often used in situations where cathodic protection is not possible.

Furthermore, it is mainly used in carbon steel storage tanks.

Corrosion inhibitors

Corrosion inhibitors are chemicals that react with the steel surface or surrounding gases to prevent corrosion.

They form a membrane on the surface of the steel to protect it from the environment.

Inhabitants can be applied to steel as a solution, coating or gas to form a protective film.

The Wikipedia article Corrosion inhibitor For more information you can contact us.

Design and detailing

Structural and architectural design plays an important role in preventing corrosion, and employees need to know how to prevent corrosion.

The detailing of the structural element must be done in a way that does not promote corrosion.

The following essential aspect can be highlighted.

- Reasonable access

The design must allow sufficient access for regular maintenance. If for any reason we are unable to access the structure, inspections and maintenance cannot be carried out.

If access is not possible through traditional methods, it must be taken into account during planning and necessary changes or adaptations must be made at the planning and design stage.

- Dust collection

The construction could be designed so that dust does not accumulate on the steel elements. Although we have applied protective coatings, their durability largely depends on whether they are dry or wet.

Moisture and dust are a good environment for rust. Therefore, we must take care to avoid the formation of rust.

- Air movement

In the corridor, care is taken to ensure that the air does not become stagnant. Once chlorides come into contact with moisture, corrosion is inevitable.

Adequate circulation could therefore avoid such problems.

- opening hours

Without openness we cannot build anything.

We need to access what we create. Because we created it to use it.

However, it is recommended to use fewer openings to prevent air from entering the components and thus preventing corrosion.

If there are openings in or near the roof, moisture, chlorides, etc. can enter the building. If the building is located close to the sea and the openings are predominantly arranged in the direction of the wind (wind front), the risk of corrosion is very high.

To avoid corrosion, these problems must be taken into account in the preliminary design and avoided as much as possible.

- Regular inspections

It is recommended to regularly monitor steel structures to find out their condition.

Regular inspections can determine if there are any issues with the durability of the structure.

If you notice this problem, you can take action in the early stages before it gets worse.

maintenance

Regular maintenance is mandatory for steel structures, whether they are galvanized and painted or we use any of the other methods described above to prevent corrosion.

After regular inspection of the structure, necessary maintenance work must be carried out.

Failure to carry out maintenance can increase the severity of defects and reduce the durability of the structure.

Furthermore, failure to carry out regular maintenance work increases the costs of later rectifying the defect.

Additionally, instructions on how to avoid corrosion can alert maintenance personnel.