Underwater concrete is a type of high-performance concrete that has been used in the past, present and future. It is a special type of concrete for special purposes.

Underwater concrete is used for the construction of bridge piers, ports, sea and river defenses, offshore oilfield development, and foundations in soils with high water levels. This type of concrete can be used to build offshore and onshore structures. Using these types of concrete prevents water isolation. This reduces construction costs and minimizes disruptions. Furthermore, works can be carried out quickly.

Underwater concrete is a high-performance type of concrete. It performs well on key performance indicators such as strength, functionality and service elevation.

Special attention required during underwater construction

- Specially designed to improve underwater construction performance.

- Required careful monitoring

- The selection of appropriate materials, the use of special equipment for quality control and special attention to construction methodology are very important.

- Sufficient attention to mixed design

- Stability depends on rheological properties and placement conditions

Main characteristics of underwater concrete

- The cement content is in the range of 380-600 kg/m 3

- Water-cement ratio in the range of 0.34 – 0.46

- Sand/aggregate ratio 0.42 -0.5

- If the water-cement ratio is low, the cement content increases. Underwater concrete is therefore generally a high-strength concrete.

- In general, these types of concrete harden quickly.

- If this flowing agent are used, the high fluidity is increased and the water-cement value is reduced.

- Anti-washout additives can be used to increase the yield strength and viscosity of the mixture. This improves wash resistance and segregation resistance.

- Highly fluid concrete that distributes its own weight.

- Archives good compression without vibration.

- Less segregation and bleeding of concrete.

Underwater concrete – concreting process

Underwater concreting is a demanding job because it involves a location that cannot be seen. If we can see with the naked eye, anything can be done if something goes wrong. Therefore, as explained above, special care is required when concreting this type of work.

Let's discuss each concreting method in detail.

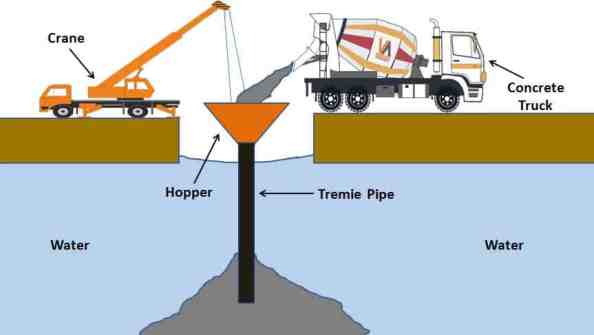

Tremie Method

This method is most common in underwater construction. This method is most often used in Pile Foundation Construction. In addition, another construction method is as Pillar Foundation. Concreting work in civil construction is also carried out by this method.

There are some important factors to consider when concreting using the contractor's method.

- The contractor must be placed below and must touch the ground surface.

- When concrete is poured into the hopper, it must first be sealed so that no concrete enters the tube.

- After the concrete is placed in the hopper, the seal is opened and the concrete moves through the tube.

- Then the pipe must be moved slightly upward so that the concrete can flow. Once the concrete is moving and stable, fill the hopper.

- Then the contractor moves slightly upward. However, the contractor must not go beyond the top surface of the concrete. The contractor must always remain on the concrete until completion of concreting.

- Then the top concrete surface that comes into contact with the water remains unchanged.

Pumping technology

Concrete can be pumped directly to the site of use.

Unlike the tremie method, this method required a lot of skill and labor. It is used for underwater concreting where other conventional methods cannot be used.

Hydraulic valve method

This method uses pipes to pour concrete. It is somewhat similar to the contractor method.

However, there is a difference. The weight of the concrete balances the movement of the concrete. When concrete is poured, it moves under the action of gravity.

Pneumatic value method – underwater concrete

Pneumatic valves connected to the end of the tube control the movement of the concrete. They can be operated externally to control the movement of concrete.

Skipping Method for Underwater Concrete

This method prevents the concrete from being washed away and the concrete can be placed in the desired position.

The following figure shows the jumping method and the opening/closing position of the bucket.

There are also other processes for underwater concrete.

- Tipper pallet shipping process

- Ready-made concrete

- Gag bag methods

- Concrete Bag Process

Related Articles on Concrete

- Concrete honeycombs

- Expansion joints in concrete

- How to choose the type of concrete

- Concrete properties

- Concrete Mix

- Concrete vibration

- Concreting temperature