Sulfate-resistant cement is used when construction is carried out in aggressive environments where chemicals such as sulfate are present.

Sulfate-resistant cement is a special type of cement used in construction. However, it is not commonly used and is sometimes not used due to lack of knowledge about sulfate-resistant concrete.

What is sulfate resistant cement

In short, it is a type of cement used in construction to resist sulfate attacks. It is a type of cement that has been adapted with tricalcium aluminate (C3A) to achieve the required properties.

According to BS EN 197-1:2011 there are three main types of sulphate resistant cement.

- Sulfate-resistant Portland cement

| Type | C 3 A clinker content |

| CEM I-SR 0 | 0% |

| CEM I-SR 3 | ≤3% |

| CEM I-SR 5 | ≤ 5% |

- Sulfate-resistant blast furnace slag cement

| Type | C 3 A clinker content |

| CEM III/B-SR | No requirements |

| CEM III/C-SR | No requirements |

- Sulfate-resistant pozzolanic cement

| Type | C 3 A clinker content |

| CEM IV/A-SR | ≤ 9% |

| CEM IV/B-SR | ≤ 9% |

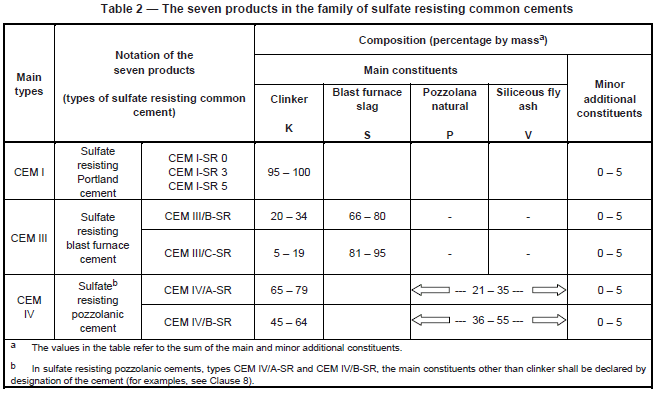

Furthermore, the following table from BS EN 197-1 lists the clinker contents and proportions of other additives for each type of cement.

Properties of sulfate-resistant cement

- Fineness 280±10 µm 2 /kg

- Setup time 80 minutes

- Final setting time 240 minutes

- Ignition Loss 0.02

- Greater compressive strength

- Maintain strength and durability

- Low heat of hydration – prevents cracking

Use of sulfate-resistant cement

- Coastal structures – dikes, breakwater structures

- Bridge pier

- Water storage/treatment

- Sewer lining

- chemical industry

Advantages of sulfate-resistant cement

- Excellent resistance to sulfate attacks

- Low heat of hydration reduces cracking.

- At low heat of hydration, the formation of delayed ettringites is also lower.

- Fewer shrinkage cracks

- High compressive strength allows for economical construction

- Increase the durability of concrete

- Minimum risk of reinforcement corrosion

Disadvantages of sulfate-resistant cement

- When producing sulfate-resistant concrete for use in marine environments, sulfate-resistant cement must be used with great care.

- If there is a risk of chloride attack, it is not advisable to use this type of cement.

- Proper hardening of concrete has to be done

- The cost of this type of concrete could be higher.

Related articles

- Types of cement

- cement

- Low heat cement

- Cement classification

- Cement and cement additives

- Cement Tests