The use of different welding techniques depends on the application and availability of the technology required to perform each type of welding.

Welding involves joining one or more metal parts. There are different classifications and many types of welding with these classifications. The following method can be used to classify welds.

- Welding with or without filler metal

- Depending on the welding power source

- Arc and non-arc welding

- Fusion and pressure welding

Let us discuss the basic types of welding in detail.

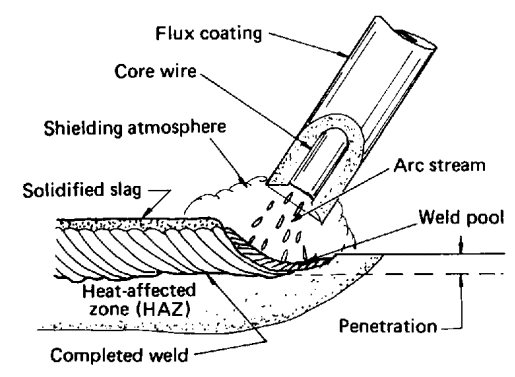

Manual arc welding

This is the most used type of welding due to its simplicity and flexibility of application.

- No pre-process is required and welding can begin as soon as the material is ready.

- The electrode can be guided manually and held comfortably.

- This method does not use any protective gas

- There is a flux coating around the electrode

- The quality of the weld depends solely on the welder's experience and skill.

- Mainly used in shell construction

- The electrode diameter is in the range of 2.5-6 mm.

Automatic welding with continuously covered electrodes

- The welding method is the same as manual arc welding.

- Unlike manual arc welding, continuous welding is performed here.

- The welding wire is mounted so that it automatically moves to the desired position at the welding speed.

- This is best suited for repetitive jobs

- And when welding at long distance, this method is more convenient compared with manual arc welding.

Inert gas welding

- This gas is also known as metal-active gas, CO 2 or inert gas

- Shielding gas is used for welding non-ferrous metals. Argon or helium are used as a shielding gas.

- Unlike manual arc welding, these types of welding do not involve flux.

- The weld pool, arc and electrode are protected by gas shielding. This may be why these types of welding are called gas shielded welding.

- Typical electrode diameter for structural work is in the range of 0.75-2.00 mm.

Submerged Arc Welding

This welding technique is slightly different from the other types when compared to the other welding methods.

- In these welding processes the arc is completely submerged.

- Therefore we can use a higher current without risk of air pollution or splashing.

- With some modifications to the system, these types of welding can be carried out completely automatically.

- The welding quality is comparatively higher because there are defined processes and due to the automatic nature

- The typical electrode diameter for structural welding is in the range of 2 to 5 mm.

Electroslag welding

- This is an automatic welding process

- Used for butt welding of thick, vertical or nearly vertical steel plates.

- The boards are cut square and are approximately 30 mm apart.

- Copper cooling shoes move along the weld seam surrounding the weld pool.

- Cooper cooling shoes cool the weld with circulating water.

There are other different welding processes. These welding processes are also predominantly used in industry.

- Gas Metal Arc Welding

- Tungsten inert gas welding

- Arc welding with cored wire

- Laser beam welding

- Electron beam welding

- Plasma arc welding

- Atomic hydrogen welding

Some of the articles related to steel structure design are as follows

- Welding defects

- Welding Test

- Destructive testing of weld beads

- Non-destructive testing of weld beads

- Single angle design for tensile stress according to EC3

- Dimensioning of screw connections according to Eurocode 3

- Practical example of constructing a single-angle section

- Design of metallic pillars according to EC3 – worked example

- Steel column design according to Eurocode 3

- Worked example of constructing a steel beam (universal beam)

- Bending and torsion (theory and calculation)

- Steel beam construction to BS 5950

- UB section classification according to BS 5950