As civil engineers know, the use of concrete retardants has become increasingly important in recent years. They allow for the proper timing and use of the various elements of a construction project, helping to ensure that the work is completed properly and efficiently. In this blog post, we will take a closer look at concrete retardants and provide useful information for structural engineers considering their use.

Once the first phase of cement hydration begins, any remaining workability is quickly lost. Concrete hardens to the point where a “cold joint” forms as more concrete is added to it. This results in surface defects and, in severe cases, structural weakness in shear due to poor adhesion between the newly placed concrete and the previous load introduced during concreting.

In hot climates and/or during large pouring operations where significant delays can occur in placing a concrete face, retarders are particularly useful in solving this problem. As concrete approaches its initial state, they provide its main advantage.

Concrete Retarder: What is a Retarder

Concrete retardants are substances added to concrete to delay or delay the setting process. This can be useful in many different situations, such as when working in hot weather or when concrete needs to cure more slowly to avoid cracking. There are several types of concrete retardants available on the market, and choosing the most suitable one depends on the specific needs of the project.

It is possible, although not always easy, to delay the setting of concrete for nearly as long as necessary using chemical retardants. The most common retardants consist of sugar. The retarder dosage must be adjusted to the required delay time, the reactivity and fineness of the cement, the actual temperature of the concrete produced and the ambient temperature.

The retarder dosage must be adjusted for each individual situation, making two to three experimental batches or, in more difficult situations, using a factorial design plan. It is also possible to slightly delay the setting of the concrete or regulate the temperature of the concrete in the summer by cooling it with ice and/or liquid nitrogen.

Effects of retarders

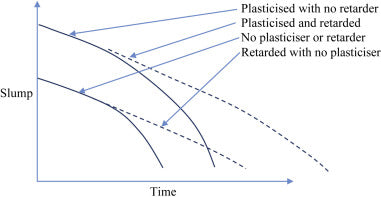

Retarders have a chemical effect on cement and delay the first phases of the hydration reaction. This should result in greater workability retention, as well as a delay in setting and hardening of the mixture.

The only effective strategy to ensure adequate workability at a late point after mixing is to start with a high initial slump, for example, using a higher dose of superplasticizer. In fact, the early loss of workability is not mainly due to cement hydration.

The following figure shows the behavior of retarders.

Strength

The use of concrete retardants would delay the initial strength gain of concrete. However, it would have no influence on this Compressive strength of concrete .

Concrete workability

They would compliment you Concrete Workability . In the initial phase, the concrete slump would increase. When we did this Flow Agent Acts as a Water Reducing Additive and retarders can lose their slump resistance over time.

This would result in segregation of concrete with subsequent poor workability of concrete.

Theft loss

As mentioned previously, the workability of concrete decreases over time and the slump of concrete decreases. This is a common problem when using modern additives.

One way to solve this problem is to redose. It can be used in accordance with the manufacturer's recommendations and the maximum allowable dosage of the mixture should not be exceeded.

Bleeding

Delaying concrete action may lead to concrete bleeding.

demarcation

Concrete segregation is related to the stiffness of the concrete mix. Reduction in concrete workability or concrete cracking could lead to this. Poor workability of the concrete is to be expected, as this takes some time.

Advantages of using concrete retarder

One of the main benefits of using concrete retardants is that they can help improve working conditions for construction workers. In particular, they can help avoid the dangerous and health-damaging situation of having to work in extremely hot weather conditions. By delaying the concrete setting process, workers can escape the heat and feel comfortable and safe.

Another advantage of using concrete retardants is that they can improve the quality of the final product. In some cases it may be necessary to delay the setting of the concrete to allow for adequate curing. This can help prevent cracks and other defects in the final product.

Finally, concrete retardants can also help improve the efficiency of the construction process. By delaying the setting of concrete, workers have more time to complete their tasks. This can result in a faster, more efficient construction project.

Different Types of Concrete Retarders

As mentioned earlier, there are different types of concrete retardants available on the market. The most common type is calcium chloride, which is added to the concrete mix to slow the setting process. Other common types of retardants include sodium gluconate, sodium bicarbonate, and ammonium sulfate.

Choosing the right concrete retarder depends on the specific needs of the project. For example, calcium chloride is a good choice for hot weather conditions, while sodium gluconate is a better choice for projects that require a longer setting time.

University Degree

Concrete retardants are an important tool for civil engineers and can provide a number of benefits for both workers and the finished product. There are several different types of retardants and choosing the most suitable one depends on the specific needs of the project.