Tensile strength of rebar and compressive strength of concrete are the two most important strength parameters we consider during construction planning.

We use Reinforced Steel when concrete is subject to tensile stress and its strength is not sufficient to support the loads.

Thus, the reinforcing steel of the structural element is intended to work together with the concrete. Steel is weak under compression when interacting. Composite action is the best solution to this problem.

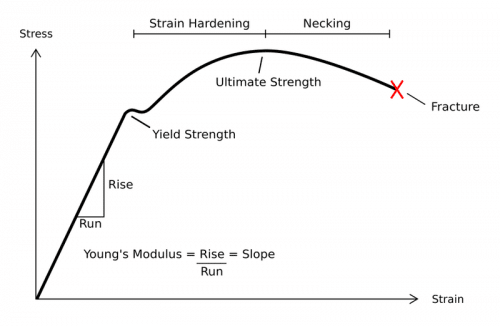

Let us consider a typical variation of the stress-strain of reinforcement bars.

What is the tensile strength of reinforcing steel?

The figure above shows the typical variation in stress hardening and strain hardening of steel.

Initially it is straight and at a certain point (we call it giving) it becomes non-linear.

Reinforcing bar tensile strength is the maximum stress (limiting stress) to which the reinforcing bar is exposed when stretched.

This is the peak, after which constriction begins and then the tension decreases as shown in the figure above. The tensile strength of rebar is a very important factor that we need to know in non-linear projects.

In linear constructions, the strength of the reinforcement is generally considered up to the yield limit. However, by focusing on nonlinear designs, we make the most of the stress that rebar can withstand without failure.

Seismic projects, structural projects for explosive loads, projects for random loads, etc. mainly require the non-linear region of the reinforcing steel.

Variation in tensile strength of reinforcing bars

There are deviations in the tensile strength or breaking load of the reinforcing bars.

As the strength of the reinforcement increases, its elongation decreases. Therefore, less stretching (or tension) is required to reach maximum tensile stress.

As shown in the figure above, tensile strength increases as the grade of reinforcing steel increases. However, the load is less until failure occurs.

How to Test the Tensile Strength of Rebar

First, the samples to be tested must be selected. Sampling is carried out in accordance with relevant codes of practice or project specifications.

According to BS 4449:2005, three specimens per 30 tonnes must be tested for each nominal diameter.

Various testing machines have been developed to perform tensile strength testing. The following figure shows a typical test machine.

As shown in the figure above, the sample is positioned and then force is applied until it fails.

Now let's examine the typical stress-strain relationship of rebar to understand the development of tensile strength.

- As the reinforcing bars are loaded, their elongation gradually increases. Up to point A, stress and strain are proportional and reducing or increasing the load within this range does not result in permanent deformation of the bars.

- The ratio of stress and strain in this area is also called modulus or moduli of elasticity . (E=σ/ε).

- If the load increases, the stress reaches point B, called the Stretch Limit where the reinforcement begins to flow. The voltage at which flow begins is called Stretch Limit .

- From point B to point C is the yield producing which is an increase in voltage for a smaller change in voltage and this is a plastic (permanent) deformation in the bar.

- Beyond the yield point, the material changes its crystalline structure and becomes stronger and resists deformation. Therefore, additional stress is required to produce additional plastic deformation beyond point C. This phenomenon is known as Work Hardening At the end of this process, the load reaches its maximum value.

- Maximum stress (point D) is the maximum tensile strength that is reached before the stress is relieved.

- If you stretch the bar beyond point D, the cross section of the bar will be reduced. This local reduction in cross section is called constriction .

- With the reduction in cross-section, the load carrying capacity of the bar decreases significantly and it ends up failing at point E. The resistance at which Reinforced Steel fails is known as Breaking Strength .

- Furthermore, there is a deviation from the curve above indicated by the dashed line with the reduction in the cross-sectional area. Therefore, the actual voltage/actual voltage will be higher than indicated.

This is the process associated with boost testing. As explained above, the maximum tension that the bar can withstand is called tensile strength.

Project code requirements

According to BS 4449:2005 there is no limit to the tensile strength of reinforcing bars. However, standards such as ASTM have established a minimum value based on the steel grade.

The following table, taken from a technical document, presents these values.

The Booster Testing article More information about booster testing can be found here.