Building in an area with sulfate in the soil and avoiding sulfate attacks is a real challenge. The sulfate resistance of a structure can be achieved in several ways, as explained in this article.

It is extremely important for engineers to understand the factors to consider during planning and construction to create a durable and safe structure.

Let’s talk about small but important things to know…

What are the sources of sulfates?

Sulfate can occur in soil and groundwater. This may have the following causes:

- Naturally

- Waste from the chemical and mining industries

- Industrial wastewater

- Sea water

Sulfate in seawater is quite common; other sources are not always found;

How do you recognize sulfate?

Sulfate is diluted in water, even if contained in the soil, when the water table comes into contact with these soils.

It is common practice to perform soil studies prior to construction planning to determine soil parameters and to use geotechnical design data to determine foundation type.

But as you can see, they don't tend to test groundwater to ensure that no harmful materials are present Durability of concrete although it is a very important test that needs to be done.

The types of tests that need to be carried out regarding water are discussed in the article Factors Concrete Mix Design

What is sulfate attack?

Sulfate attack is the reaction of sulfate ions with concrete and the creation of new formations within the concrete.

The resulting combination of chemical compositions tends to increase the internal volume of the concrete, resulting in internal stresses.

Such expansions lead to cracks, loss of concrete strength, loss of elastic properties, etc.

Furthermore, sulfate attack can be identified as another type of damage to concrete. The extent of the damage depends on the sulfate levels the structure is exposed to.

There are three main stages of sulfate attack.

- Ettringite formation

- Gypsum formation

- Magnesium ion reaction

Ettringite formation

It is a quite popular term that delayed ettringite formation in concrete is due to temperature increase above 70ºC. 0 C (general limit) in the hydration process.

Similar formations also occur during sulfate attack.

Let's look at the main points of the foundation.

- Sulfate ions entering the concrete react with calcium aluminate hydrate and form calcium sulfoaluminate hydrate, which is also called ettringite, 3CaO.Al 2 Ó 3 .3CaSO 4 .32H 2 Ó.

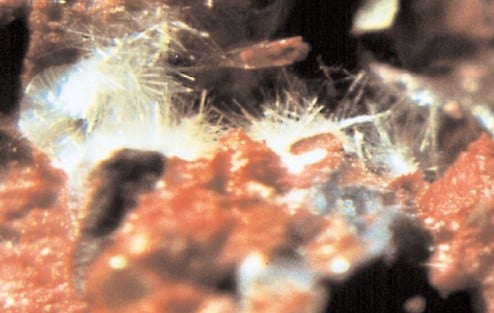

- This material is distracting and excessive.

- The volume of the solid is greater than the original volume

- They grow like countless needle-shaped crystals.

Gypsum formation

- Sulfate ions (SO 4 2- ) can react with calcium hydroxide Ca(OH)2. Gypsum is also known as calcium sulfate dihydrate, CaSO. 4 .2H 2 O.

- The formation of plaster increases this volume, which can cause cracks and loss of elastic properties.

Reacts with magnesium ions

- When magnesium ions are accompanied by sulfates, a reaction occurs.

- Magnesium ions react with calcium hydroxide and produce brucite, also known as magnesium hydroxide, Mg(OH). two .

- It is poorly soluble and precipitation from the solution leads to an increase in the volume of solids.

- Furthermore, magnesium ions react with calcium silicate hydrate, the main binder of hardened concrete, causing loss of the concrete's elastic properties.

What happens if sulfate attacks concrete?

- Descaling

Descaling is the decomposition of hydrated calcium silicate. This is the material that holds the main bond.

This reaction significantly affects the elastic properties and leads to loss of strength of structural elements.

- Increase internal volume

The internal volume of concrete increases as sulfate reacts to form ettringite and gypsum, which form crystals. This creates internal expansion stresses.

- Cracks in concrete

When the internal stress exceeds the tensile strength of the concrete, the concrete begins to crack. These cracks may not be visible at first until they develop on the surface.

- Reinforcement corrosion

The formation of cracks to the surface can lead to radiation from the reinforcement to the environment and corrosion of the reinforcement.

How to Build a Permanent Structure

It is possible to design a structure that resists sulfate attacks. We cannot move the structure to another location. Instead, we can design and build with the necessary safety measures in place.

These steps can be identified in this process.

- Design in accordance with code provisions

- Modify the cement

- Protect the structure from the outside

Sulfate resistance design in accordance with code regulations

Modern regulations place more emphasis on structure durability. There are special provisions for the selection of materials, especially cement.

Let's find out how to achieve sulfate resistance using cement and water.

- BS EN 1008:2002 limits the sulphate content of concrete mixing water to 2,000 mg/l.

This can be checked by carrying out a soil test. A water test can be used to determine if the value is within the limit.

- Selection of cement content, concrete grade, etc. based on exposure conditions

A structure built in an environment containing aggressive chemicals must meet several building regulations.

BS 8500-1:2015+A1:2016 is the latest code available to select the type of cement according to durability requirements.

-

- Select the aggressive chemical environment exposure class for concrete (ACEC class) from Table A2 depending on the available sulfate content and other values.

- The nominal reinforcement coverage can be selected from Table A10. The same table can also be used to determine DC class.

- The limit values of concrete composition and properties for each DC class can be found in Table A12. Selection of the maximum water-cement value, the minimum cement or combination content and the type of cement and combination (as indicated in Table A6) can be done through Table A12.

- In addition, tables A4 and A5 apply, depending on the period of use and other exposure classes.

Modify cement

- Table A6 of BS 8500-1:2015+A1:2016 gives the types of cement and cement combination. CEM I -SR 0, CEM I -SR 3, CEM IIB+SR, CEM IIIA+SR and CEM IIIB+SR are specified as sulfate-resistant cement blends.

- The basic components of these cements and cement combinations can be modified as needed.

- Tricalcium aluminate (C 3 A) is kept at a minimum level to reduce the extent of the reaction with sulfate ions.

Protect the structure from the outside

- The first step could be, if possible, the foundation of the structure placed above the water table . This avoids/minimizes the contact of groundwater with the concrete surface.

- The seal To prevent the structure from being exposed to the external environment, a membrane can be installed. In general, waterproofing is guaranteed for up to 10 years. If the structure has been built for 50 years, this solution may not be the best. However, it will provide some protection.

- application of external coatings .

- Deployment Layers of casualties . The thickness of the concrete can be increased to allow chemicals to penetrate the sacrificial layer. This method may not be applicable to some structures, such as friction piles, where the surface must be of good quality to support the load. However, in other places, such as normal foundations, this method can be used.