The construction sector is looking for alternative materials, such as sea sand, as other resources are currently rotting. If cleaned properly, using sea sand for construction can be one of the best alternatives.

Initially, river sand was used as fine aggregate for construction. Later the use of manufactured sand also became popular due to its benefits.

The growing demand for construction materials has led to a shortage of construction materials supply. Furthermore, it has been observed that some projects are delayed because materials do not reach the construction site on time. Furthermore, a constant supply of materials is becoming increasingly difficult these days.

Growing environmental concerns about extracting river sand from riverbeds have limited its extraction. In addition to the impact on the environment, the excavation of rivers has led to the collapse of bridges, support structures, soil erosion, collapse of rivers, etc.

In this context, the use of sea sand for construction purposes is recommended as a sensible solution to the problem. There are other benefits to using sea sand.

Benefits of sea sand

- Sea sand particles are round or cubic, just like river sand.

- The grain size of sea sand is finer than that of river sand.

- Does not contain mud or organic materials.

- They are readily available but require cleaning.

- The classification of the material and its consistency are additional advantages.

- Mining can be done at a reasonable cost.

- Countries bordering the sea can make full use of this natural resource.

Disadvantages of sea sand

- Reinforcement corrosion

- Cost and time required to wash sea sand

- Production may require greater capital investments

- Shell included

- Higher chloride content

Can we use sea sand for construction?

The most frequently asked question is: “Can we use sea sand for construction?”

The answer is: yes, it is possible.

The main problem with sea sand is containment shells and chlorides .

Influence of mussel content and other contaminants

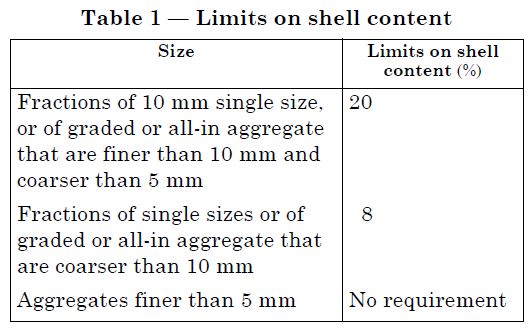

Offshore sand largely contains shells. According to BS 882 1992 there are no shell content requirements for aggregates smaller than 5mm. See the following table from BS 882 1992.

Although some argue that shell content has an impact on compressive strength, according to BS 882 1992 There is no set limit for an aggregate greater than 5mm. Some study results have shown that aggregates larger than 5 mm have no effect on the compressive strength of concrete.

Furthermore, the size of bowls is also limited to 5mm if the size of aggregates is limited to 5mm.

However, shell containment is known to have an impact on the workability of concrete.

Limit values for chloride content

Chloride attack is one of the factors that affect the durability of concrete . Sea sand contains more chloride ions than permitted, causing serious durability problems. Therefore, great care must be taken when using offshore sand in construction.

The chloride content in concrete is generally limited to 0.4% of the cement mass. BS 5328 Part 1 1997 sets this limit and BS 882 1992 has slightly higher values (0.5%). The following table is taken from BS 5328 Part 1 1997.

The studies carried out by the researchers showed that the chloride content should be limited to 0.3%. Furthermore, if we are concerned about the durability of concrete, we must limit the chloride content as much as possible.

How to clean offshore sand

The most common method is to store sea sand in the ground and let it purify naturally. The impurity content is continuously checked from the beginning of filling until use.

Rain, in particular, washes away materials from the sand and makes it clean.