Artificial sand (M sand) is used as a substitute for river sand in construction. River sand becomes a scarce resource at certain times of the year because there is not enough rain and the sand cannot be collected in river beds.

Artificial sand can be considered a by-product of the coarse aggregate production process. When rock is crushed into small particles, fine aggregates are created.

Due to the increasing demand in the construction sector, it is difficult to continuously supply return sand to meet demand.

Nowadays, construction is progressing faster than in the future, so fine crushed sand (M sand) is used as an alternative to river sand.

Can we use artificial sand for construction?

The answer is yes . However, when using M-Sand in construction, some restrictions must be taken into account.

Furthermore, artificial sand is used as a total or partial replacement for fine aggregates.

Before use, the grain size or particle size distribution, mica content, etc.

A mica content greater than 5% leads to loss of concrete's compressive strength. Therefore, the use of mica-containing aggregates in construction must be carefully considered.

Different standards provide a similar range of gradations for the selection of sand produced.

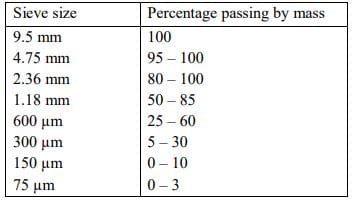

If we test them according to the ASTM standard, the following particle distribution can be considered.

ASTM C33/C33M-13 provides the above pass percentages to define the grading curve of crushed fine aggregates.

In addition, BS 882 also contains the specification for fine aggregate selection.

To determine the grain size of the sand produced, all guidelines can be followed.

The grain size of sand M must be taken into account as it can vary constantly. Therefore, tests must be carried out continuously.

Why should we use artificial sand?

Let's discuss the most important factors in favor of using M-Sand.

- Lack of materials

The continuous use of sand has led to the end of available resources. In addition, the sand is mainly removed from the lapel. The lack of rain led to a reduction in sand production.

- Growing demand

Due to the development of the construction sector and rapid growth, there is a greater demand for aggregates. It became impossible to provide the materials to meet these needs.

- Difficulties with transportation

Most of the time sand is collected from distant construction sites and has to be transported to the construction sites. Due to traffic congestion, transportation is very difficult.

- Laws

There are laws against transporting and extracting river sand.

- Impurities in the sand

Sand can contain contaminants such as silt and clay. This affects the strength of the concrete.

- Illegal production

Some people make sand by washing sandy clay. These types of sand contain more impurities like mud around the particles, which do not allow them to bond with cement. This can result in a significant loss of concrete strength.

- By product

M sand is a by-product of the production of rock material. If necessary, in small quantities, the sand produced in the production of coarse rock material can be used.

Advantages of artificial sand

- Costs Less : Artificial sand is cheaper compared to river sand. Contributes to greater cost-benefit in construction.

- Continuous supply : To meet construction needs, artificial sand can be supplied continuously and easily.

- impurities : M sand has fewer impurities. Does not contain materials such as silt, clay, etc. and offers better performance. Furthermore, it does not contain organic and soluble compounds that affect the setting time and properties of the cement. Normally the strength of concrete is not affected by contaminants.

- High strength concrete : According to the various studies carried out by researchers, the sand produced can be considered as a replacement (total or partial) for river sand. Based on studies, users of manufactured sand increase the Compressive Strength of Concrete . Furthermore, some studies show that Adding 50% M-Sand gives better results as complete replacement of river sand.

- High resistance to splitting

- High flexural strength

- Good abrasion resistance

- Durability of concrete : Compared to river sand, artificial sand contains fewer impurities. M-Sand does not contain silt or clay. Furthermore, its chemical composition is balanced as it is extracted from good rock. Concrete made from M-Sand can withstand harsh environmental conditions. It also reduces corrosion and permeability of reinforcement. In general, it presents good resistance to factors that affect the durability of concrete .

- Workability of concrete : According to studies Workability of concrete increases when using artificial sand.

- Construction errors: There are fewer design errors such as: For example, honeycombing, segregation, bleeding, etc.

- Environmentally friendly : M-Sand is an environmentally friendly material that does not cause much harm compared to river sand. Deep excavations sometimes cause damage to bridge piers, dams, etc. River sand causes more environmental and social problems. In addition, the use of river sand causes increased erosion, destruction of flora and fauna, damage to roads caused by sand transport, reduction of rivers and natural beds, etc., which also causes serious problems.

Disadvantages of artificial sand

- Continuous and consistent testing : Regular testing is required to ensure the consistency of the sand produced.

- Presence of impurities : M sand may contain impurities such as coal, bones, shells, mica, etc. The degradation of these materials over time can reduce the strength of concrete.

- Ecological damage : The production of M sand causes environmental problems. The vibrations caused by the explosions damage buildings in the surrounding areas. Dust dispersed in the environment causes serious environmental and social problems.

- High volume of fines : M sand contains a large amount of microfine particles compared to river sand. This can affect the workability and strength of the concrete.