Due to their comprehensive development, concrete additives have become an indispensable part of modern concrete structures and improve the quality, workability, strength, etc.

Given the widespread use of these materials, it is very important to pay attention to concrete additives.

The first patent for calcium chloride in concrete was granted in Germany in 1873, and the additives have a longer history, according to the literature. Modern additive technology began in North America in the 1930s with the basic air-entraining agents, retarders, accelerators, and water reducers.

Admixtures are chemicals added to concrete, mortar or mortar during mixing to change the properties of the concrete. The following benefits generally describe the purpose of its use.

- Reduce construction costs

- Achieve certain properties of concrete more effectively than with other methods

- Maintains concrete quality until installation

- To overcome certain emergencies during concreting work

Additives are divided into different categories depending on their function. Air-entraining agents, water reducers, retarders, accelerators and plasticizers (superplasticizers) are considered by many to be the main categories of additives. However, the following categorization provides more information about the types of additives.

- Air entraining additives

- Water reducing additives

- plasticizer

- Accelerator additives

- Retardant additives

- Hydration regulating additives

- Corrosion inhibitors

- Reduced shrinkage

- Alkaline-silica reactivity inhibitors

- Color additives

- Various additives, e.g. for processability, bonding, moisture sealing, permeability reduction, grouting, gas formation, washout protection, foaming and pumping aid.

BS EN 934-2:2001 provides a similar categorization as follows. Furthermore, this was done based on the testing procedures and available product ranges.

- Water reducing/plasticizing additives

- High quality reducing/superplasticizing additives

- Water Storage Additives

- Air entraining agent

- Define accelerator additives

- Additives that accelerate hardening

- Setting the retarder

- Water repellent additives

- Setting retardant/water reducing/plasticizer additives

- Highly effective retardant/water reducer/superplasticizer additives

- Accelerator/water reducing/plasticizer additives.

All additives must be tested before use in accordance with the recommendations of the relevant code of practice.

Additive Testing

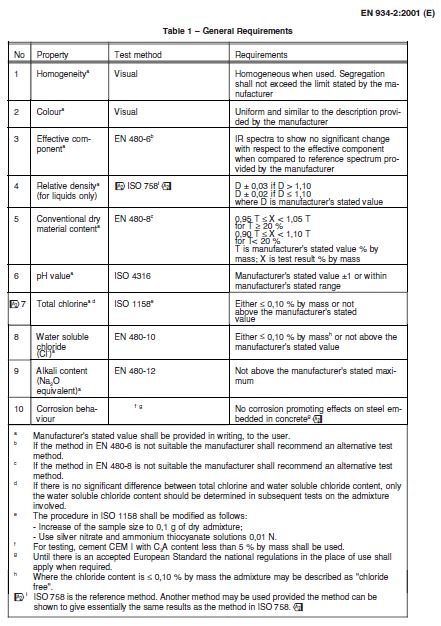

The general requirements that an additive must meet can be found in Table 01 of BS EN 934-2-2001. Particular attention must be paid to the uniform dispersion of powder additives with a retardant effect.

For the test methods and requirements of the above 11 types of additives (categorized according to BS EN 934-2-2001), reference is made to Table 02 to Table 12 of the same code. Additionally, all factory production must be inspected according to the minimum requirements specified in the code.