Tunnels are designed into reservoirs or underground roads are not built every day like other structures. They could be built on rock or earth.

For example, a tunnel built for a highway is designed to support external loads from cover rock or other covering material.

However, water-bearing tunnels are designed for external and external loads.

When the tunnel transports water at high pressure, it exerts water pressure on the surrounding area. Especially when there is less rock cover, we need to check whether the cover is sufficient to support this load if the tunnel is not lined.

When lining a tunnel, we need to consider the loads that will act on the tunnel and the tunnel must be designed with these factors in mind. There is also a risk of collapse in the area around the tunnel.

Depending on the type of surrounding material, a tunnel can be constructed.

Tunnels with high-quality rock cover are generally not lined with reinforced concrete other than spray construction.

However, at the exit, the tunnel must be lined with a steel or concrete lining if the rock cover is insufficient. Most tunnel planners face this situation. Typically, they determine how far the unlined section can continue and the remaining length is lined.

Design a section with an appropriate rock cover

If there is sufficient rock cover, we can design the tunnel with or without lining. If we have good quality rock, we can build an unlined tunnel. However, if the rock is weak, we need to consider the quality of the rock when designing.

Tunnel design for external loads

If there is enough rock cover, there is no need to worry about the tunnel collapsing completely.

However, local failures may occur. If the rock is not of sufficient quality or cannot be stabilized with shotcrete (reinforced or not), we must have a coating that can withstand external loads.

The liner design takes into account the type of rock.

The quality and type of rock must be checked on site before planning is carried out. In tunnel construction books or standards you can read which loads must be taken into account when planning the tunnel lining, depending on the type of rock.

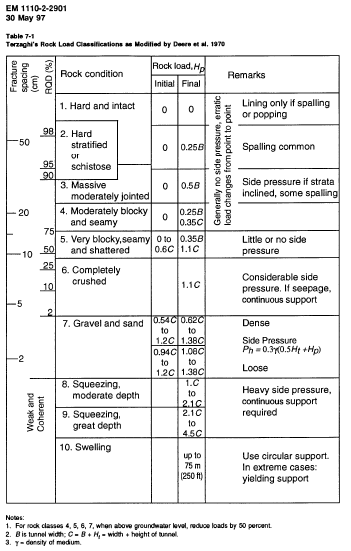

“EM 1110-2-2901 Tunnels and shafts in rock” is one of the most used standards that we can use in our projects. Provides a guideline for tunnel construction depending on different terrain conditions.

The value above was taken from EM 1110-2-2901. Depending on the condition of the rock, the crack spacing and the RQD value, the rock load can be selected. For example, if we consider massive and moderately fractured rocks, the charge on the rock is 0.5 B.

Hp = 0.5 B x (rock density)

Suppose the diameter of the tunnel (B) is 2.5 m

Rock density 25 kN/m 3

HP = 0.5 x 2.5 x 25

= 31.25kN/ m2

This load can be applied to the tunnel as a gravity load. To determine tunnel stresses, finite element analysis or equations provided in codes for different tunnel shapes can be used.

In addition to rock loads, external water pressure must also be taken into account during design. If there is no adequate drainage system, the project must take into account the water column or part of it.

When the proper drainage system is in place, external irrigation water pressure can be reduced or nearly eliminated in the design.

However, the design water pressure can be considered as the lower value of 25 percent of the total pressure and a pressure corresponding to a water column with a height of three tunnel diameters.

Loads must be taken into account when analyzing the tunnel. EM 1110-2-2901 contains a table that can be used to create load combinations.

Load combinations can be created considering the factors indicated in the table above.

If lateral deformation occurs, this increases the bending and shearing forces of the tunnel. If there is a large rock cover, the tunnel cannot deform laterally.

This can be taken into account in the analysis and the rock can be considered as support for the tunnel.

The rock support can be a model depending on the type of rock. The underground rock response can be calculated using the equations from EM 1110-2-2901.

Depending on the arch angle, element size, positional response and rock modulus, the underground response can be calculated in both the radial and tangential directions.

The figure above shows the graphical representation of the underground response.

We must apply the background reaction as shown in the figure.

Depending on design requirements, the tangential bottom reaction may be omitted.

Furthermore, when we model the tunnel with software, the springs must not be subjected to any tensile stress. Only the compression condition needs to be taken into consideration, as the rock cannot withstand tensile stresses.

Tunnel design for internal loads

If there is sufficient rock cover, the internal load can be supported by the surrounding rock due to water pressure. Even if there is a large rock cover, the tunnel cannot deform. Therefore, there are no stresses caused by the internal water load.

Design a section with an insufficient bedrock

High quality rock is found in areas where tunnels are built. However, there are cases where we find poor quality rock or soil at the top of the tunnel. Even if we have high-quality rock, it must be sufficient to absorb the internal stress that water pressure exerts on the surrounding rock.

Design for external loads

If the rock cover is not sufficient, it will be necessary to use steel or concrete casing to support the internal loads.

If the tunnel does not carry water, it will not exert internal pressure on the surrounding rock. External loads acting on the tunnel lining must be taken into account during planning.

The technical article “ Large Tunnels at Bad Rock 2000 Terzaghi Lecture by Evert Hoek ” can be called a draft. It is a very good guide for designing such cases.

However, different methods for calculating rock load have been proposed in studies and books.

EM 1110-2-2901 provides a guideline for finding a location that requires the aligned section. In addition to this position, the section can be created as an unlined section if necessary.

To determine the required distance for the line section, the following figure from EM 1110-2-2901 can be used.

Figure 9-2 shows the stone cover required for unlined pressurized waterways.

This is the Norwegian criterion for delimiting rocks. This concept is a method commonly used by designers.

This is a very simple technique and tool for determining the minimum stone coverage for an unlined tunnel. The weight of the rock mass or cover is balanced by the inner head of the tunnel.

When searching for rock cover(s), attention should be paid to surface conditions.

For example, if the top covering is made of weathered earth or rock, this type of material can be washed away when water flows along the surface.

Furthermore, the safety factor must be sufficiently taken into account. It can range between 1.05 and 3 and can be related to the design intent.

Figure 9.1 shown below can also be used for tunnel planning. We can choose a method and then start planning. The most used and simplest method is the Norwegian limitation criterion.

Once we select the criteria, we can calculate the section that needs to be aligned using the equation provided in the guideline.

The external load that must be taken into account in the design is the weight of the rock cover or roofing material.

We can apply this weight as a gravitational load for analysis.

If there is a large rock cover in the lateral direction, we can consider the rock as a support against lateral deformation. However, if there is insufficient rock cover in the lateral direction, it is advisable not to consider it as support.

Design for internal loads

If the rock cover is insufficient, the tunnels must be lined as described above.

The water pressure can be considered as an internal load, while the overburden weight can be considered as the load exerted by the top of the structure as a gravitational load.

Depending on the height of the load and the deformation of the tunnel, the weight of the clogged material must be handled very carefully.

Sometimes it can be beneficial, but it can also be a harmful burden.

For example, when we apply a factor when creating a load combination, it creates a weight that is greater than the existing weight of the waste material.

This can increase the lifting moment and reduce the deflection moment. In fact, this depends entirely on the analysis we do. Therefore, it is better to be very careful about the weight of the covering material if we want to apply it to the model.

In addition, the item design and construction of Tunnel crossing For more information on this topic you can also consult here.