Beam construction is a broad field that covers a large area of construction. The beam is one of the main elements of structures.

There are different types of bars that can be categorized using different methods. The following categorization can also be used.

- Reinforced concrete beams

- Precast concrete beams

- Fiber-reinforced supports

- Steel beams

There are many other types as well.

We discuss the construction of the following types of beams on this site.

- Construction of bridge beams – construction of prestressed beams

- Floor Beam Design

- Steel beam construction – construction guide and standards requirements to BS 5950

- Metal Beam Structure – Worked Example; Universal carrier

- Simply reinforced beam design according to Eurocode 2

- Beam construction to BS 8110

- Reinforced double beam construction to BS 8110

- Concrete beams (design and detailing)

- Prestressed composite beam (constructive aspects)

- 6 Causes of Beam Failure (Designer's Guide)

- Dimensioning of a simply reinforced beam; Design aspects

- Beam Shear Sizing

- Deep jet design

- Dimensioning when cutting beams according to Eurocode 2

In this article, we will focus on the various aspects of design and code regulations.

Let's discuss the design process.

- Load calculation: The design load to be applied to the beam should be calculated in accordance with relevant codes of practice.

- Carrying out an analysis: Bending moments, shear forces and torsional moments must be evaluated. This can be done by manual calculation or using computer software.

- Then continue with the reinforcement calculation.

Before we start designing, we first create the initial draft where we determine the final dimensions of the section.

First draft

At this stage we finalize the sizes of the members.

Since most construction projects had limited time to complete the designs, designers first completed the foundation drawings to proceed with construction and then released the remaining drawings.

The first project made it possible to carry out a load assessment of the foundation after preparing the general layout.

The initial design is carried out in accordance with the relevant standards and based on the assessment of structural behavior.

Let's look at some of the methods available for initial beam construction.

The following method is explained in accordance with British Standards (BS 8110).

- Firstly, we need to select the rebar cover based on durability and fire resistance requirements.

- Then we can calculate the following effective depths depending on the boundary condition of the element.

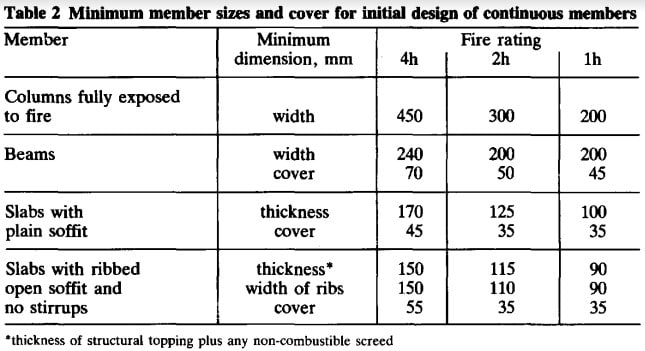

The following table can be used to evaluate the section.

The table above presents the minimum thickness/width of the cross-section and the performance of the reinforcement according to the fire class.

From the table above we can select the appropriate effective span/depth. If we know the span, we can calculate the effective depth according to the constrained condition.

The dimensioning of the elements taken in the initial phase may not correspond to the final project if we are based only on the values obtained by this method.

We may also use our experience and judgment to select appropriate limb sizes.

Bar analysis and design

Once the initial dimensioning of all elements has been completed, the structure can be modeled and designed according to the loading needs.

Structural analysis can be performed manually or using a computer program. If it is a simple beam such as a simply supported beam, the calculation is much easier and can be done manually.

However, when things get more complex, using software saves time.

After determining the bending moment and shear forces, the design of the beams can be carried out according to the working examples and explanations in the relevant code.

You can refer to the detailed explanations and working examples listed above when constructing the beam.

Special note on beam design in serviceability limit state

All projects must meet the limit states for use.

Usage limit tests of the following type are carried out.

- Limit beam deflection

- Limit the crack with the beams

- Consideration of the durability aspect can also be considered a maintenance requirement. Selection of suitable reinforcement coverage, concrete quality, etc.

We also use reinforcement detailing methods to control problems at the limit of operability.

For example, adding reinforcement to prevent cracking.

Detailing the beam reinforcements

The detailing of the reinforcement is of great importance for analysis and sizing.

In the design of beams, constructability and idealization of the construction in the drawing are essential.

Design considerations must be reflected in construction. For example, if we are considering a connection that allows rotation, the reinforcement detailing must be done accordingly.

The following articles published on the website will provide guidance on reinforcement detailing and handling requirements. Additionally, you can refer to relevant detailing guides.

- Beam Reinforcement Details

- Shortening of beam stiffeners

- Support side reinforcement

Let's summarize the beam construction process

The following sketch illustrates the detonation process.