Ground improvements are carried out specifically for shallow foundations when they are built on weak soils. Based on the classification of the soil under the foundation, the type of improvement is selected. The nature of the loads is also taken into consideration when finalizing the improvement technique.

There are many methods for improving soil. However, the most appropriate method should be selected based on available resources and applicability. Additionally, accessibility must also be considered. The following methods are most commonly used for this purpose.

- Vibratory compaction

- Vacuum consolidation

- Soil preloading

- compaction vibrating columns

- Resource

- Improvement through additives

- Dynamic soil compaction

Vibratory compaction

Soil compaction by vibration is called vibrocompaction. In this method, loose soil is vibrated to change the configuration of the soil to a dense form. The strong vibration rearranges soil particles into a configuration that reduces the proportion of pores and increases density. This method is best suited for sandy soils.

Soil improvements through vacuum consolidation

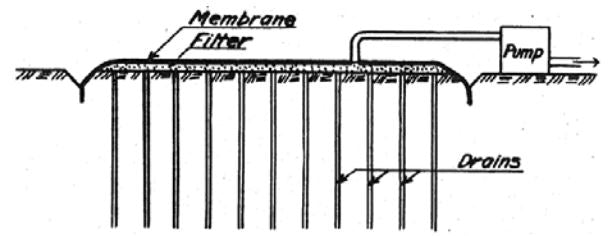

Vacuum consolidation is a soil improvement technique for soft soils. Vacuum pressure is exerted on the floor, which is protected from loss of surface pressure by a sealing membrane.

Perforated vertical drainage systems embedded in the ground create negative pressure in the soil and allow irrigation water to drain. As a measure of acceleration or, if necessary, for greater compaction, in addition to the load in the form of a vacuum, a load pressure can also be exerted on the ground.

Figure 01 shows the basic arrangement of vacuum consolidation. This method is mainly used in infrastructure development projects, dredging and land reclamation, etc.

Soil preloading

Preloading or precompression is a process of applying a load to the soil to remove irrigation water over time. Reducing irrigation water causes soil to settle and is an economical method if soil is easy to find for this purpose.

This is done before construction as it takes a reasonable amount of time to achieve the necessary settlement, depending on the project requirements. This procedure can be carried out for compressible soft soils (soft to medium soft), such as saturated clay and silt, organic clay, peat, etc.

Primary settlement, secondary settlement and an improvement in undrained shear strength due to prestressing are expected. The effect of settlement on the support structure is thus minimized, as shown in Figure 02.

Stone Column Vibratory Compaction Set

Vibratory compaction refers to the insertion of densely packed stone columns into the ground. This method is suitable for improving soft soils such as clay, cracks, etc. By introducing stone pillars, the bearing capacity of the soil is significantly improved.

It is an economical and environmentally friendly method. However, economic efficiency may vary depending on the availability of the machines used for this purpose.

Soil improvements through grouting

Grouting is most commonly used as a soil improvement method in foundation work, particularly in infrastructure projects such as dam construction. This method can also be used in civil construction if there is soil with compression.

In large infrastructure projects, such as dams, mortar is used to fill voids in the rock and reduce permeability. Filling with mortar increases cohesion and shear strength.

Cement-based mortar mixes are often used and, depending on project requirements, additives may be added to help the mortar cure quickly.

If the soil is weak and the permeability is sufficient for the mortar to flow, it can be injected into the oil to improve its bearing capacity. This can be done according to the recommendations of the geotechnical engineer. Various injection methods are used in industry, particularly at shallow depths.

- Compaction injections

- Permeation pressing

- Blasting process

Figure 04 shows the different grouting methods used in the construction industry.

Soil improvements through additives

When people talk about additives, they don't always mean the chemical additives that most people think of. There are mainly two types of additives, namely inert additives and chemical additives.

Inert additives consist of inert materials that do not react with the soil, but improve density, grain size distribution, shear strength and bearing capacity and reduce porosity and permeability.

Chemical additives generally include lime, cement, industrial waste and combinations of industrial waste and other commercially available chemicals.

Industrial waste is made up of different materials

- Coal combustion products such as fly ash and bottom ash

- Ground Blast Furnace Slag (GGBS)

- Cement Kiln Dust

- Lime kiln powder

Subsoil improvements through dynamic soil compaction

Dynamic compaction involves dropping heavy weights into the soil at regular intervals to increase the soil's density. This method is used in infrastructure projects, especially when a large area needs to be improved.

The weight to be eliminated is selected depending on the level of compassion required. The selection is made under the guidance of the geotechnical engineer. This method is suitable for all granular soils listed below.

- Non-organic

- Inhomogeneous filling

- Artificial land (areas of land created through land reclamation)

- Recultivation areas with different characteristics

- If there are underground obstacles

- Soils with large air voids (garbage deposits, poorly filled soils, etc.)

There are other benefits to using this method, such as compacting large areas of loose granular fill, reducing the volume of landfill waste, increasing soil density and bearing capacity, and reducing post-construction settlement.