Punching around pillars, piles, etc. Typically checked on foundations, slab foundations, pile caps, flat slabs, etc. The definition of punching shear varies slightly depending on the standard.

The punching force is the shear force or shear stress considered at the distance from the supporting surface (e.g. the column surface) to a distance specified in the standards. The circumference around the specified distance is taken into account to calculate the punching force and shear stresses. Once the shear stress is known, it can be checked whether shear reinforcement is necessary taking into account the value Vc calculated for the specific section. Based on the shear stress and shear capacity values, a decision is made whether shear reinforcement is required.

The variation of the punching range for different patterns is explained in the thread.

PIERCING THE EUROCODE 2

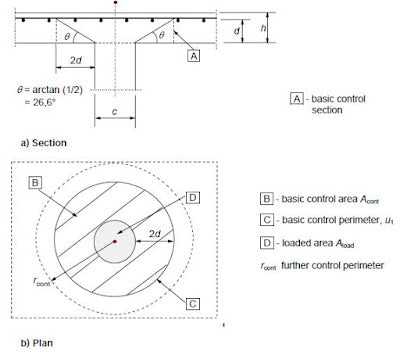

The shear volume for solid slabs, cassette slabs with solid surfaces above columns and foundations can be calculated as shown in the following figures. The shear volume is viewed from the support surface in 2d.

Depending on the location of the supports, the circumference calculation must be adjusted. The length and location of the punching circle are determined as shown in the following figure when the holder is not centered.

Additionally, if the support is close to an edge, the following method should be followed.

DRILLING SCISSORS PERIMETER BS 5400 PART 4

The method for calculating punching shear in solid plate is given in BS 5400 Part 4 1990 and is slightly different from Eurocode 2. The distance to punching circumference is 1.5d in BS 5400 while it is 2d in Eurocode 2.

PERIMETER IN ACI

The amount of shear considered in the ACI code is much less than in other codes. It is recommended to consider a distance of (d/2) from the support surface. However, other codes such as Eurocode 2 and BS 5400 assume 2d and 1.5d respectively. The following figure taken from the ACI code shows the arrangement of the shear perimeter.

Therefore, it appears that the ACI code uses a much smaller scope for punching shear calculations. If the shear force on the punch circumference is known, the shear stress can be calculated.