The difference between unidirectional cards and bidirectional cards must be understood in the design of the card. There are things that need to be discussed in detail about two types of slabs based on the load transfer mechanism from the slab to its supports, namely beams, walls, etc.

Types of plates

Essentially, there are about five types of boards.

- Disposable dishes

- Bidirectional cards

- Flat Plates

- waffle dishes

- Prefabricated panels

- Prestressed concrete slabs

In this article, we will only discuss disposable and two-way plates.

Let's understand what a unidirectional card and a bidirectional card are.

According to BS 8110, the definition of unidirectional and bidirectional plate is as follows.

Bidirectional plate = large gap / small gap ≤ 2

Unidirectional plate = Long span / Long span > 2

This is mainly necessary to evaluate the distribution of loads applied to the plate. Most manual load calculation methods are based on the flowline method.

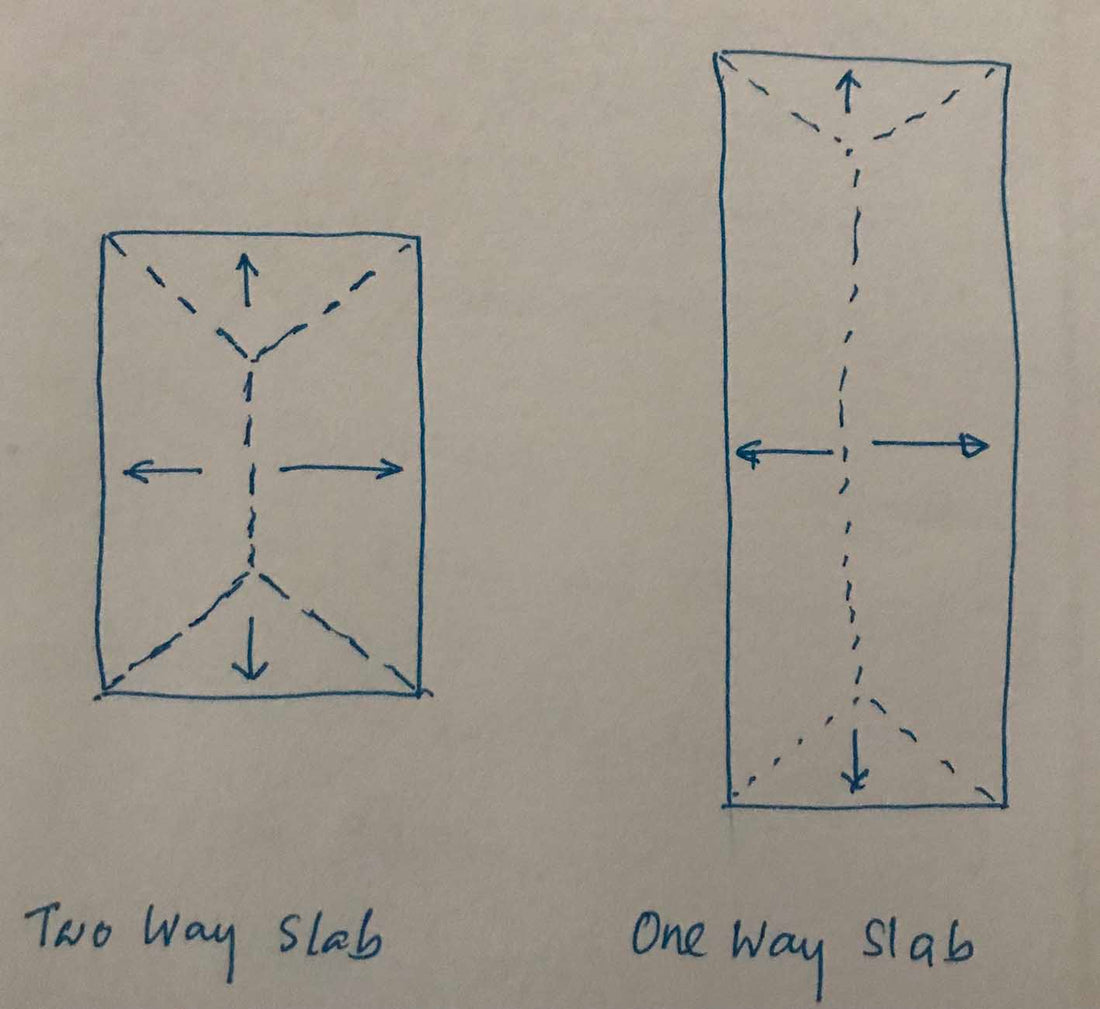

Load distribution can be used to understand the difference between uniaxial and biaxial plates. The following figure shows the typical load distribution pattern.

For biaxial plates, an increase in the center line (sagging flow line) is observed. The shorter the center line, the greater the load distribution on each side. With uniaxial plates, the load transferred to the longitudinal beams is very high and to the transverse beams it is minimal.

Reinforcement projects for one-way slabs and two-way slabs are not the same. There are different methods for analyzing and designing disposable plates. According to BS 8110 there are tables for determining the bending moment and shear force coefficients that are used to calculate bending and shear forces.

If we know the load, we can calculate the deflection and upward deflection bending moment based on the boundary conditions and the span ratio (long span/short span). In addition, there are tables for calculating the bending and shear forces of uniaxial plates.

The simple analysis method can also be used to determine bending moments and shear forces. If there is a series of unidirectional slabs and uniformly distributed loads acting on the slab, it can be analyzed as a continuous beam. The beam width can be assumed as 1000 mm.

Detailing the reinforcement

The following could be considered.

Reinforcement detail of one-way street slabs

- In general, the main reinforcements are placed in the direction of load distribution. Therefore, main reinforcement should be placed in the shortest possible direction, except where this is not possible due to connection with most other slabs running in opposite directions.

- Typically, shear reinforcement connections are not provided for slabs. However, for greater thicknesses and concentrated loads, the requirement for shear reinforcement must be verified.

- Increasing the board thickness leads to thermal problems. When the slab thickness increases above 200mm, it is necessary to check the crack control reinforcement or reinforcement requirements.

Reinforcement detailing of bidirectional slabs

- A similar method to that described on the disposable plate could be used.

- Shortening conversions to continuous supports and end supports can be carried out according to project specifications.

The article Panel construction according to BS 8110 More information about panel construction can be found here.