Expansion joints in concrete are particularly important in the construction of ground-level slabs that rest on the ground.

Different tensions on the slab can cause cracks in the slab, which damages surfaces such as tiles.

Therefore, it is very important that the panel expansion joints are checked. If we don't provide enough joints and design them correctly, the cost of fixing them would be much higher than the original cost of building the expansion joints.

What are expansion joints in concrete?

Joints that are created in panels other than expansion and movement joints. They are a type of joint that does not allow the expansion joint to move.

However, they allow some movement to reduce internal tension.

Expansion joints are also called contraction joints.

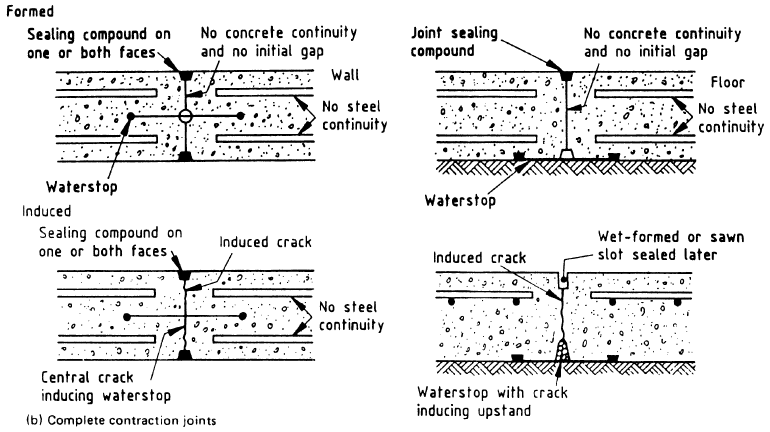

The following types of expansion joints can be identified according to BS 8007.

- Complete shrinkage joints

- Partial contraction joints

Furthermore, the formation of the contraction gap is also different.

- Molded expansion joints

The expansion joint is formed first and behaves according to the requirements of the structure.

- Induced expansion joints

Firstly, there is no separation in concrete. The grooves (slits) created at the top and bottom of the plate cause cracks.

There are different types of expansion joints as specified in BS 8007. The following figure shows different arrangements of expansion joints.

Why do we need expansion joints in concrete?

Expansion joints are used to control cracks in concrete.

For the following reasons, additional stresses arise in concrete placed as second-phase concrete on the ground or on top of the concrete layer.

- Movements caused by concrete shrinkage during concrete hardening

- Small expansion and contraction movements due to the absorption and release of moisture in the concrete

If we do not allow enough space to relieve the stresses caused by the movement of the concrete, cracks will appear in the concrete.

The crack pattern would be irregular and random. Cobweb-shaped cracks may also appear. The formation of cracks or the pattern of cracks depends on internally developed constraints and boundaries.

At this point we want to discuss the main difference between expansion joints in concrete and expansion joints.

What is the difference between an expansion joint and an expansion joint?

An expansion joint is a type of joint that does not allow for physical movement of the concrete, but does allow for the release of additional stress created in the concrete.

On the other hand, the expansion joint allows movement and the reduction of internal tensions.

Both the expansion joint and the expansion joint have different functions.

However, we generally use a combination of expansion joints and control joints when constructing slabs at ground level. We design concrete control joints within an area covered by expansion joints. We do not need to design expansion joints as control joints.

While the expansion joint reduces the voltage, the control joint can reduce the voltage to an intermediate level.

As indicated in the figure above, a grout pattern needs to be decided based on the floor layout. This way we can decide whether or not we need an expansion joint. In smaller areas, internal stresses can be reduced using expansion joints.

How to create an expansion joint

The following procedure can be used to create a joint pattern.

- As indicated in the first images, the connection can be created during construction or we can allow it to emerge as tensions develop.

- The joints formed have no connection at the joint other than continuation or interruption of reinforcement as required.

- The induced joint is caused by the formation of cracks in the slab due to internal stresses.

- To form internal cracks, a slit must be created. The depth of the groove is generally a quarter of the board thickness.

Advantages of movement joints over expansion joints

- Expansion joints are more expensive compared to control joints.

- Expansion joints can also be created later.

- The joint is more efficient than the expansion joint.

- For expansion joints, even a smaller width is sufficient and if they are thinner they can be made of flexible material without filler. However, it is possible to fill the gap with foreign materials.

- For expansion joints, it is necessary to seal the joints and pay attention to the edges, as damage may occur during vehicle movement.

Distance between expansion joints

The spacing of the shrinkage joint or expansion joints in concrete depends on many factors, as shown below.

- The thickness of the board

- Water content in concrete

- evaporation rate

- moisture

- Availability of reinforcement networks

- temperature

- Board dimensions

- Limitation by the floor or lying surface

- The geometry of the plate

And there are many other factors that can influence the spacing of expansion joints.

Unreinforced plate

- The distance between shrinkage joints can be kept in the range of 4-5 m. However, due to other factors, the distance may be reduced to approximately 3 m.

Reinforced plate

- Joint spacing can be maintained in the range of 12 to 25 m.