The screed is a flat surface made of concrete or a mixture of cement and sand for laying concrete. Depending on the specification, concrete screed can be applied in different mix specifications such as grade 15, grade 20, etc.

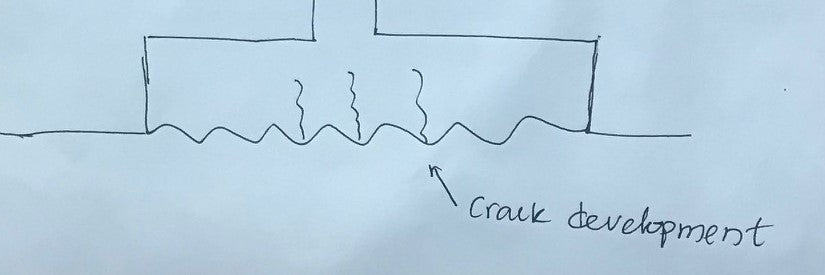

Irregularities in the concrete tension surface lead to the formation of tension cracks. There are areas where concrete is subject to tensile stress. For example, in a slab foundation, the lower surface of the concrete surrounding the column is exposed to higher tensile stresses. An uneven surface is more likely to cause stress cracking than a smooth, flat surface. Figure 01 below shows the formation of tension cracks.

Therefore, it is essential to have a concrete screed under the foundations. The thickness of the screed generally varies between 50mm and 100mm depending on the application. Greater thicknesses are used for large foundations and where soil conditions are very weak. Especially in pile top construction, the soil condition can be very poor. In these situations, a thicker screed layer, around 100 mm thick and a higher grade of concrete, such as C20, could be used.

The quality of the screed depends on the application or type of foundation. For light structures and small areas, a mixture of cement and sand can also be used. A suggested mix of 1:3 (cement:sand) can be used. However, concrete screed can be used for other structures. The quality of the screed can be mainly C15 or C20.

If no screed is laid, the water in the concrete will be absorbed by the soil before it hardens. This creates honeycombs or dry surfaces with greater porosity through which water can penetrate the reinforcement. As a result, the reinforcement can corrode over time. Ultimately, this affects the strength of the foundation.

The screed serves as the base for laying the waterproofing membrane and protects it. Sometimes polyethylene is used instead of screed. Placing polyethylene prevents water loss into the concrete, but does not create a flat surface for laying the foundation.