Due to their advantages over other types of panels, flat panels are one of the most used types of panels around the world.

The structure type offers more advantages over other types of panels. However, construction costs would be slightly higher than for a normal reinforced concrete slab. As the beams connecting all the columns are not available, a greater slab thickness is required.

Types of Flat Ceilings

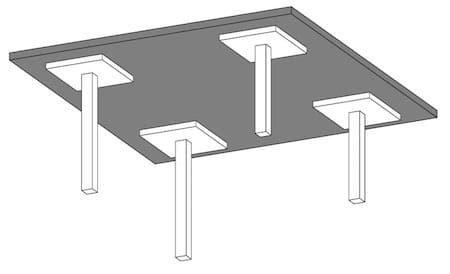

There are essentially four main types of flat panels. Namely the following:

- Flat plate

This is the common board type. Uniform board thickness continues throughout the board. Narrow span slabs can be constructed with uniform thickness. As the span increases, the plate thickness needs to be increased.

Increases construction costs, otherwise other types of boards could be used.

- Flat roof with folding panels

A drop panel is an area around the column that raises the panel to improve the load capacity of the panel. This is due to the flat plate construction.

The flat plate does not have a large load capacity. Greater bending moments and shear forces occur around the column. If the uniform thickness of the plate is not enough, we increase the thickness of the plate. This increases flexural and shear resistance.

Generally, the size of the hanging panel is relatively larger than the top of the column.

- Flat roof with column heads

The construction of capitals on flat slabs is very common. If higher transverse forces need to be absorbed at the column head and higher bending moments occur, the construction of a column head offers many advantages.

Column heads are smaller compared to drop plates. However, the depth of the pillar head is greater than that of the drop plates. Additionally, the height of the top of the column decreases. The following illustration shows a flat plate with a support head and a drop plate.

- Flat ceiling with folding plate and column headboard

The image above shows the panel with folding panel and support head. If bending and shear forces exceed the top of the column, we can provide folding panels to accommodate the increased bending and shear stresses.

Advantages of flat plate

- Flexibility in partitions. If work on the internal partition is planned after construction, planning is much easier, as there are no restrictions on the beams.

- Reduction in floor height. Since there are no bars, reduction is possible.

- Reducing floor height reduces construction costs.

- There are no interruptions in construction technology.

- Placing reinforcement is much easier compared to normal beam/slab construction

- Formwork is also simpler and lighter

- Compared to a normal reinforced concrete slab, construction time is also shorter.

Disadvantages of flat plate

- There are limitations to increasing the board length.

- Best suited for lightweight partitions. Increasing the load on the wall can significantly increase construction costs.

- Comparatively greater plate thickness is required.

- There are difficulties in controlling the deflections of the central strip of the plate.

Flat roof construction

Flat roof construction is a little different from conventional roof constructions. The fact that there are no reinforced concrete beams to transfer the load from the ceiling to the pillar represents a challenge for the construction of the flat roof.

In these types of construction, the column strip is constructed like the beam. There are several construction methods.

- Empirical method

- Subframe method

- Streamline method

- Computer-aided methods

There is modern software that allows us to fully dimension the slab and create reinforcement plans.

There are methods for determining board thickness. The table provided in ACI 318 for biaxial slabs without internal supports can be used to determine slab thickness. Based on the availability of suspended slabs and the span of the slab, the thickness for construction can be determined.

When designing a flat ceiling according to Eurocode2, the following procedure can be used

- Select the projected service life of the structure

- Determine the effects on the plate

- Select load combinations to consider

- Find charging options

- Determine concrete grade, water-cement ratio, and minimum cement content based on exposure class and durability requirements.

- Select the appropriate covering for reinforcement based on durability and fire resistance requirements

- Analyze the structure and determine the required bending moments and shear forces.

- Calculate the bending reinforcement. If necessary, we can plan thrust elements.

- Design for piercing scissors and other cutting requirements.

- Check the deflections

- Continue detailing the reinforcement.

Related articles on sign design

- Plate reinforcement details

- Difference Between Disposable Dishes and Two-Way Dishes

- Cantilever plate construction

- Plate deflection

- Panel construction to BS 8110

- Panel placement methods

- Board thickness

- Deflection of beams and slabs