Depending on the type of construction, different types of concrete joints are foreseen in the construction, as required by planning.

In general, there are concrete joints in most structures because a structure cannot be built all at once.

Depending on the type of structure and construction requirements, the following types of concrete joints are provided in structures.

- Movement joints

- contraction joints

- Expansion joints

- sliding joints

- Construction joints

- Temporary joints

- Insulating joints

Movement joints

As the name suggests, the purpose of the link is to allow movement between two structures or two components of the same structure.

A movement can have the following reasons:

- Lateral loads on structures

Lateral load may consist of earth pressure, water pressure, wind pressure or seismic pressure.

When subjected to lateral loading, the structure can move permanently or temporarily.

The structure can be permanently displaced by earth or water pressure.

However, when loaded, wind pressure, earthquakes, etc. temporarily deform the structure and then return to its original position.

- To separate irregular structures

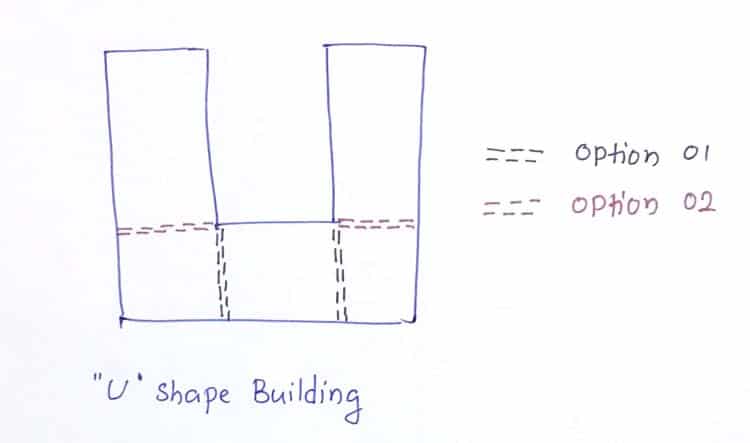

For example, if the building has a U-shaped plan, it is advisable to provide a dividing line in the building, especially if it is built on a flat foundation.

Due to the geometry of the structure, different settlements occur in the structure. If the structure is built continuously, it will create additional stresses on the structure.

This can be avoided by operating the structure as shown in the following figure.

As shown in the figure above, the movement joint can be designed according to the civil engineer's preferences.

Motion joints are present in different structures and the type of joint details varies from structure to structure. Furthermore, the allowable joint distance also depends on the type of structure and its use.

- Movement joints in foundations

- Movement joints in slabs

- Movement joints in beams

- Movement joints in bridges

Movement joints in foundations

A lot of structural information is needed to decide on this type of concrete joint. The location and type of movement joint to be provided in the foundation depend on the movements allowed in the structure.

In general the movement joint width can vary between 10 mm and 25 mm. However, on special occasions this value can even increase to 100 mm.

Expansion joints in the foundation, especially in basements, must be waterproofed to prevent water from penetrating the joint.

When movement joints are present in foundations, such as slab foundations, a surface water barrier is provided to prevent water ingress through the joint.

As the image above shows, it is more appropriate to place the water at the bottom rather than in the middle of the section.

Movement joints in concrete slabs

If there is an expansion joint in the foundation, as described above, this joint is also adopted for the slabs. In addition, the joint width can correspond to this joint.

However, if the two blocks are separated by a movement joint for seismic reasons, care must be taken when deciding the width of the joint.

The width of the expansion joint should be based on the result of the structural analysis for such lateral seismic loads.

The maximum deflection of the building must be checked, especially on the upper floors, where it is crucial to determine the width of the floor movement joints.

There are generally two columns on each side and close to the expansion joint. Both sides can be suspended to create an expansion joint in the ground.

Furthermore, other aspects must also be taken into consideration when determining the width of the movement joints. The type of installation at the joint must also be taken into consideration in the final determination.

There are many types of joint sealing methods, from joint fillers to complex mechanical systems. Depending on the adequacy and affordability of costs, other factors may be considered.

Furthermore, these movement joints are also called expansion joints. However, the function or purpose of the joint determines the type.

Construction joint details used for expansion joints can also be used for movement joints. You just need to make sure the joint allows enough movement.

Movement joints in beams

The same method used for movement joints in concrete slabs is used for beams.

The same gap and embedding details can be used. Pay attention to the height of the conveyor. Fixing details can be changed if necessary.

Movement joints in bridges

In bridges, movement joints and expansion joints are considered types of concrete joints that fall into the same category and have similar details.

In bridges, there are often no movement joints, as these generally connect several elements.

Movement joints are provided to accommodate the following structural movements.

- Creep and shrinkage effects

- Thermal fluctuations or deformations under payload.

- Allows lateral movement in the event of an earthquake.

We discuss more information about expansion joints in this article.

contraction joints

A shrinkage joint is a vertical joint that is placed in a structure so as not to affect structural performance.

Depending on the type of structure, the reinforcement is described in detail to fulfill the purpose of the connection. Therefore, a decision is made based on structural planning whether the reinforcement will be continued or discontinued.

There are basically two types of construction joints

- Complete contraction gap

The types of concrete joints in which the reinforcement and concrete are completely interrupted are called complete shrinkage joints.

Although no bending moment is transmitted through the connection, shear forces can be transmitted through rods anchored in both blocks, with one rod free to slide.

The distance between the joints is set so that the structural parts cannot crack. Furthermore, sufficient reinforcement is provided to transfer the applied forces from one block to another.

No gaps remain in the contraction gap.

If the structure retains fluids, water barriers are installed. Joint sealants can be used for all types of expansion joints.

As there is no width for shrinkage joints, bituminous material can be applied to concrete surfaces to maintain debonding.

- Partial contraction joint

The main difference between full shrinkage joint and partial shrinkage joint is the partial continuation of the reinforcement.

Purpose of the expansion joint

Expansion joints are concrete joints that serve different purposes compared to other types of joints.

As the main purpose of concrete shrinkage joints, the following advantages can be highlighted.

- Prevents accidental cracks in concrete due to concrete contraction and expansion.

- In the construction of large concrete structures, such as B. overflow channels and adjacent retaining walls, shrinkage joints minimize the formation of cracks due to thermal effects.

- Additionally, a properly designed contraction joint transfers thrust from one block to another.

- Partial contraction joint can partially withstand bending stresses.

Location of the expansion joint

In general, contraction joints are cast where no bending stresses or only low bending stresses occur.

However, they can be used to transfer momentum from one block to another.

For a plate, we offer free-end bushings to transfer shear forces.

Construction details for expansion joints

There are typical construction details for shrinkage joints. The following figure shows details of the BS 8007 contraction joint.

Where are expansion joints used?

As shown in the figure above, shrinkage joints are commonly used in floor slabs. The formation of initially formed cracked joints or shrinkage joints releases stresses in the panels due to thermal shrinkage and expansion.

Contraction joints can occur in massive construction projects, such as hydroelectric power or dam construction projects. They can be installed on retaining walls, spillway structures, etc. to avoid cracks due to stresses induced in the concrete.

Contraction joints are often used in concrete road construction. The construction of movement joints or expansion joints in a road increases maintenance requirements due to damage caused by vehicle movement.

Expansion joints

Joints that allow expansion are called expansion joints. However, it is sometimes very difficult to distinguish expansion joints from movement joints.

In this article, we focus on expansion joints in civil construction, such as buildings, bridges, roads, etc. Furthermore, we will limit ourselves to the types of concrete joints found in concrete construction.

The following types of concrete joints (expansion joints) are discussed.

- Expansion joints for concrete bridges

- Concrete road

- Terrace

- Building expansion joints

Bridge expansion joints

Many expansion joints can be observed in bridge construction. Especially in continuous bridges, expansion joints are installed to accommodate movement of concrete due to thermal problems, creep effects, shrinkage effects, etc.

Generally, bridges are constructed by connecting pillars through beams and then placing the concrete deck on the beams installed between the beam structures connecting the pillars.

The only element we have to demolish is the deck slab, as the others do not cross it and, of course, we have to demolish it, unless we do not build continuous longitudinal beams on the bridge.

When providing expansion joints for bridge decks, the following advantages should be highlighted:

- Balances expansion and contraction caused by changes in ambient temperature.

- Reduces the effects of shrinkage and creep

- Reduced likelihood of bridge deck cracking and warping, reducing movement restriction.

Bridge expansion joints can be divided into three main categories.

- Small joints of movement

- Medium-motion joints

- Large movement joints

Small movement joints in bridges

There are mainly three types of small movement joints in bridges.

- Compression Seals

Provides uniform compression and allows movement of the bridge deck. Furthermore, it improves driving comfort in the joint.

- Silicone sealants

Gaskets are molded in place and are best suited for repair work.

- Asphalt Buffer Joints

Very effective in absorbing heat movements

Medium expansion joints in bridges

This type of expansion joint can also be divided into three categories depending on the arrangement.

- Strip sealing gaskets

A neoprene membrane fixed between the straps guarantees sealing. Furthermore, the membrane is not exposed to traffic. Therefore, there is no wear and tear caused by traffic.

Additionally, it acts as a barrier against water.

- finger joints

Two segments are anchored at each point and the movements are plane.

Finger joints are concrete joints widely used in bridge construction.

It's more durable.

- Sliding Plate Joints

Two overlapping plates absorb movements.

Improves drawing convenience, the following figure shows a similar arrangement.

Large expansion joints in bridges

Modular bridge expansion joints are mainly considered movement joints of large bridges.

However, the finger expansion joint can also be placed in the same category because it allows significant movement.

- Modular bridge expansion joints

This type of concrete joint is used to accommodate comparatively larger movements. The joint is made of steel.

The arrangement of the joints allows the vehicles to move evenly. Additionally, there is uniform movement as the seal expands and contracts.

Additionally, it prevents water and debris from falling through joints and provides protection to underlying structures.

Expansion joints for concrete roads

To prevent additional stresses on concrete due to thermal contraction and shrinkage, expansion joints must be installed in roads at regular intervals.

Additionally, soil movement under the concrete pavement can also cause cracks in the concrete if it is not sufficiently separated by the joints.

Joint distances are in the range of 3-5m.

There are reinforced and unreinforced concrete floors. However, reinforced paving stones are more durable and remain crack-free for longer.

The following types of concrete joint details can be adopted in road expansion joints. Source: Technical document.

Sometimes it is observed that contraction joints are also installed instead of expansion joints. Installing shrinkage joints improves operating conditions. However, the width of the joint is not sufficient for thermal movements.

Expansion joints on terraces

Roof expansion joints are concrete joints that are typically not the preferred option for compensating for movement in the structure.

However, for unavoidable reasons, it is necessary to install expansion joints on the roofs.

- If a building is made up of two blocks and they have different periods of vibration, in these situations the required joint width is provided.

Lateral deflection can be caused by wind or earthquake.

- When sealing, especially membrane sealing, and roof insulation, it is necessary to apply the concrete layer to the insulation.

The thickness of the concrete is about 50 mm and prefabricated mesh (BRC mesh) can be predominantly used to prevent cracks in the concrete.

Furthermore, the concrete dimension is maintained around 12 m 2 Expansion joint is provided every 12 m. 2 concrete. The joint width can be about 10-15 mm.

For wider joints, a prefabricated assembly can be used to seal the joint. If the width is in the range of 10 to 15 mm, a suitable sealant can be used to seal the joint. M

Bituminous sealants are most commonly used for roofs because they can withstand high temperatures and are comparatively durable.

Expansion joints in buildings

The dimensions and type of building materials have a significant impact on the lateral movement of buildings due to thermal expansion and contraction.

For example, the length of a steel building is greater than that of a concrete building.

Therefore, it is necessary to limit the dimensions of the structures and provide expansion joints that allow lateral movements.

Technical Report 65, “Expansion Joints in Buildings,” from the National Academy of Sciences provides comprehensive guidance on this topic.

The following figure from the same guideline shows the limitation of the connection depending on the construction material and temperature variations.

For more information and methods for calculating building extensions, it is worth studying the guide.

sliding joints

Joints that allow movement between two planes are called sliding joints.

According to BS 8007, a sliding joint is a joint that allows two components to slide relative to each other with minimal restrictions.

With these types of joints, a total loss of the component can be observed. The reinforcement is interrupted and there are no embedding or shear wedges.

For example, a joint in the base plate may be detached in the construction of a cylindrical tank. The following figure shows a similar type of joint.

More information about the sliding joint can be found in the Garpédia article.

Construction joints

The most commonly used type of joint is the construction joint. Construction joints are necessary in almost all constructions.

The important factor in how we treat the construction joint is when the second leak occurs.

Particular attention is paid to molded construction joints in water-retaining structures.

Furthermore, in the case of higher bending moments and shear forces, construction joints must be placed in such a way that these points are avoided. Furthermore, construction joints in special constructions must be specifically treated.

The continuation of reinforcements, dowels, shear wedges, etc. That's what's special about a construction joint.

The Construction Joints article discusses this topic in more detail and is worth reading for more information.

Temporary joints

These are types of concrete joints rarely used in construction.

These joints are installed in long structures when thermal contraction is critical, especially during the construction phase.

In the second stage, a width of approx. 1 m free for concreting. In most cases, the reinforcement is also interrupted at the joint to allow for lateral movement. Water dishes are also provided if watertight requirements exist.

The following image shows a temporary joint used in construction. Reinforcement continued in the joint. However, depending on the type of construction, the reinforcements can be interrupted and overlapped.

Insulating joints

Isolation joints have different purposes. They can be used to isolate structural elements, concrete elements and other elements such as wood, brick, steel, etc.

If it is necessary to take into account construction movements at various stages, an isolation joint can be used.

For example, if we need a cavity until construction is complete or if we need to close part of it later, we can form an isolation joint.

A spike could be kept around the opening and later a plate could be constructed and supported on the spike.

Furthermore, changes in material properties at the junction of two elements can cause cracks. Providing such a connection can minimize this.

In summary, it can be said that the insulating joint is a joint in structures that allows relative movements.