As the name suggests, destructive weld testing is performed by taking samples or damaging the weld. If it is difficult to determine the problem or a more detailed evaluation of the welds is required, destructive testing of the welds is performed.

Welding defects Reduce the strength of the connection and lead to structural failure if we do not pay attention to it.

The following types of destructive tests of weld beads can be identified.

- Macro Recording Test

- Fillet Weld Break Test

- Transverse tensile test

- Guided bending test

- Free bend test

- Backbend Test

The need to carry out destructive tests to evaluate resistance and evaluate properties is decided based on the importance of the work and the information collected during the work Welding test .

Let's discuss each type of destructive testing in detail.

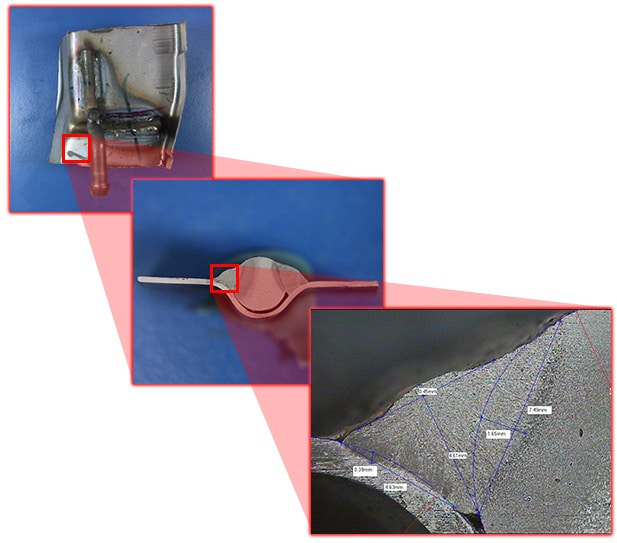

Macro Etching Test – Destructive test of weld beads

This method is also known as acid etching testing.

The appearance of the weld is checked by applying a chemical to the weld sample taken for the weld joint. The summary of this test is as follows.

- Take a small sample of the welded joint.

- The sample is polished to access the section.

- It is then etched with a mild acid.

- This makes the internal structure of the weld clearly visible.

- This test can be used to check the following.

- depth of penetration

- Lack of fusion

- Insufficient root penetration

- Internal porosity

- Fusion line cracks

Since such welding tests do not provide any information, they may be used more frequently to evaluate the quality of a weld.

Fillet Weld Break Test

This is a type of weld strength assessment. Since the strength of a weld seam depends on many parameters, a general assessment of all these parameters can be performed using a fillet weld fracture test.

For this test we need to collect weld samples as it is a non-intrusive testing method for welds.

This test can be summarized as follows.

- The test weld fillet is broken on one side.

- The sample is loaded from the unloaded side in the transverse direction of the weld seam.

- This value increases until the fillet weld fails.

- The defective sample is then examined to identify discontinuities in the weld and the length of these discontinuities.

- This test is often used in conjunction with the Macro Etch test to provide more information.

- This type of destructive weld testing can detect the following.

- Lack of fusion

- Internal porosity

- Slag inclusion

Transverse tensile test

Most of the time, weld is designed for tensile strength. Therefore, the following factors need to be evaluated.

- weld metal

- Base metal tensile strength

- The connection between the weld and the base metal

- Heat affected zone

The tensile properties or tensile strength of the weld seam are determined by loading the sample to failure.

- Tensile strength/tensile strength refers to the maximum load that was absorbed during loading.

- These values can then be compared with the project requirements.

- The tensile test is one of the best tests to determine the strength of a weld.

Guided bending test

This test is a measure of the ductility and strength of welded joints.

The sample is bent according to the specified radius. Some of the following aspects can be highlighted as relevant to this test.

- Generally, this test is performed across the weld axis.

- This is the most commonly used type of destructive testing of welds to determine welding performance and process.

- These tests can be used to evaluate internal enamel defects.

Free bend test

This is a type of free bending test used to evaluate the performance of a weld.

This test evaluates the ductility and metallic deposits of welded joints.

When performing a guided weld bead test, free bending testing is generally not necessary as a destructive test of weld beads.

Some of the articles related to steel structure design are as follows

- Single angle design for tensile stress according to EC3

- Dimensioning of screw connections according to Eurocode 3

- Practical example of constructing a single-angle section

- Design of metallic pillars according to EC3 – worked example

- Steel column design according to Eurocode 3

- Worked example of constructing a steel beam (universal beam)

- Bending and torsion (theory and calculation)

- Steel beam construction to BS 5950

- UB section classification according to BS 5950