Concrete cracks and concrete crack repair are very common in the construction of concrete structures. Cracks in concrete are inevitable. However, it depends on the depth and width of the crack.

- A crack width of less than 0.1 mm is not considered a problem for water-retaining structures where aesthetic appearance is important.

- In general, the crack width limit for water storage structures is 0.2 mm.

- In normal constructions, the crack width is limited to 0.3 mm. However, this value may need to be adjusted depending on the exposure class.

Another problem with cracks in concrete is the depth of the crack. The formation of cracks in the reinforcement is the main problem regarding the durability of the structure. This can lead to corrosion of the reinforcement and rapid deterioration of the structure.

Why does concrete crack?

The formation of cracks can have several causes. Some of the main reasons are as follows.

- Shrinkage Cracks

- Thermal cracks – due to heat of hydration

- Thermal cracks – due to the change in temperature of structures

- Structural Cracks

- Cracks caused by chemical reactions

Methods for repairing cracks in concrete

Depending on the treatment of the crack and the type of repair, a distinction is made between different methods of repairing cracks in concrete.

- Epoxy resin grout injection

- Polyurethane injection

- To sew

- Mending

- Gravity filling methods

- Drilling and doweling methods

- Flexible seal – channel and seal

- Autogenous healing

- Movement joints, expansion joints and retraction joints

In addition to those mentioned above, there are other methods of treating cracked concrete. They are not directly related to crack sealing, but can also be considered a secondary method of solving problems. Additionally, some of these methods may require one of the above methods to seal the cracks. Sealing the crack with a flexible sealant can be done to prevent deterioration of the concrete and corrosion of reinforcement.

Secondary methods – Indirect methods – when a crack affects the load capacity

- Adding Additional Reinforcements

- preload

- FRFP

- Steel Beam Support

- Growing section

- Provide additional support

Let's discuss each crack sealing method in detail.

Epoxy resin grout injection

What is epoxy mortar? It is a type of mortar with the following properties.

- Very low viscosity

- Does not shrink

- Stronger bond to steel than cement

- High adhesion to concrete, higher tensile strength than normal concrete

- Develop greater compressive strength than concrete

- High shear bond strength

- High chemical resistance

Epoxy mortar is fluid and can penetrate very small cracks. It is also applied with pressure to fill the entire crack. It is the most suitable type of structural crack repair. .

When repairing concrete cracks with epoxy mortar, the following procedure can be used.

- The crack may have penetrated to a certain depth or across the section.

- First, clean the area where the concrete crack needs to be repaired. Cement paste, dust, paint, filler, etc. must be removed. This needs to be done to a width of about 50 mm.

- Generally, repairing cracks with epoxy resin mortar is done by injection with a little pressure.

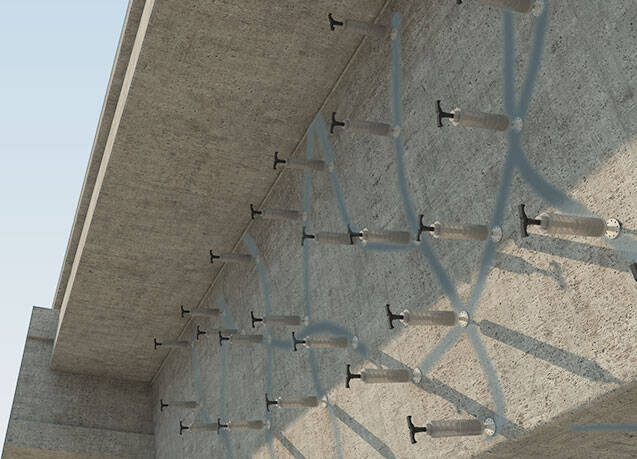

- Install the injection nozzles. They can be fixed at a maximum distance of approx. The distance can be selected depending on the length of the crack.

- Seal the surface crack with mortar or appropriate epoxy adhesive. If the crack has penetrated the entire section, nipples can be installed on both sides. For example, on a slab, nipples can be placed on both sides to ensure that the entire crack is filled with mortar.

- A width of about 50 mm can be sealed, and the thickness of the sealant applied to the surface can be at least 2 mm. Must cure as specified in the product specification.

- Injection of the epoxy grout should begin at one end when the horizontal cracks are sealed. Injection/filling must continue until the mortar comes out of the next nozzle. Then repeat the process.

- Injecting epoxy grout should start at the bottom when sealing a vertical crack.

- The mortar injection pressure can be maintained in the range of 0.1 to 0.5 MPa. However, this can be decided in consultation with the engineer and in accordance with product specifications.

Polyurethane injection

Polyurethane injection is not a common method for repairing cracks in concrete compared to other methods. However, in the presence of water it is more effective and efficient.

Furthermore, polyurethane injection has advantages and disadvantages compared to epoxy resin injection.

- If there is a risk of material leakage, polyurethane injection is suitable

- Not used to repair structural cracks

- Polyurethane expands approximately 2 to 40 times its original volume. It is suitable for filling voids in concrete.

- These fast-setting elastomer formats are suitable for sealing cracks in water-retaining structures.

- Polyurethane is very useful because it starts to harden within a few minutes. Reduces movement of crack material.

- The elastic nature of the sealant allows for slight structural movement in the crack.

- High injection pressure may be required to inject into fine cracks.

To sew

Repairing cracks in concrete by stitching is not as effective as filling them with epoxy mortar. It is a method in which the two concrete parts separated by the crack are connected together.

- To prevent the crack from widening, a steel bar is inserted into the concrete on both sides.

- It holds the two concrete segments together.

- May be suitable for repairing structural cracks. However, in my opinion, it is advisable to choose a method such as epoxy grout injection when structural crack repair is required.

- This method may be best suited for walls without structural elements, such as brick walls.

- The holes made for inserting the steel wire/rod can be filled with epoxy resin mortar.

Mending

Patching is one of the simplest and easiest methods of repairing cracks in concrete. No complicated tools or highly qualified specialists are required. However, technical personnel capable of meeting product specifications must be available.

- Crack sealant is applied to the surface of the crack. If eustatic appearance is a problem, the sealant will be applied after a groove is cut in the concrete.

- A V-shaped groove is cut along the crack and filled with sealant.

- Non-shrink construction mortar is generally used as a sealant. Its volume does not decrease as it hardens and it gains strength very quickly. The strength of construction mortar is approximately 50-60 N/mm. two .

- Anti-shrinkage construction mortar can be applied as a filler in the cracked area. It can even be applied to ceilings and vertical surfaces.

Gravity filling methods

This crack filling method has some similarities to epoxy grout injection. However, they are not the same. Furthermore, different materials are used in this method.

- This method can even be used to seal concrete cracks with a width of approximately 0.03 mm. This requires the use of very low viscosity epoxy resin grout.

- Normal mortar cannot penetrate if the width is smaller. It can partially seal the crack, thus affecting the structural performance of the structure.

- Since there is no pressure, when sealing a structural crack or a fissure in a water-retaining structure, attention must be paid to the effectiveness of the system.

- If in doubt, another method is always recommended, such as epoxy resin injection.

- As we know, filling very small cracks less than 0.1mm wide would not be so easy under gravity pressure.

Drilling and doweling methods

This method of repairing cracks in concrete cannot always be used because the crack pattern does not develop as desired and is irregular.

- This method is suitable for almost straight cracks

- Suitable for vertical cracks.

- One hole or several holes can be drilled into the crack.

- It can then be filled with suitable non-shrink construction mortar or epoxy resin mortar.

- In most cases, vertical cracks in concrete walls can be treated with this method.

Flexible seal – channel and seal

When repairing concrete cracks, it is not always necessary to seal the entire crack. If it is possible to leave the crack as is, crack sealing methods such as flexible sealants can be used.

- Cracks in concrete, cracks in masonry, etc. that are not affected by static can be sealed through grooving and sealing processes.

- Furthermore, with this method we can repair cracks caused by thermal influences and where there is continuous expansion and contraction.

- First, a V-shaped groove must be cut along the crack. The crack can then be filled with flexible sealant.

- For wider cracks, depending on the width of the crack, a wire filler may be inserted into the crack to minimize the use of sealant.

Autogenous healing

Autogenous curing is not an artificial method for repairing cracks in concrete. It is a method in which the crack in the concrete heals itself.

- Autologous healing involves the formation of calcium carbonate (CaCO 3 ) crystals.

- Approximately 2+ Ions on the surface of the crack react with water. They migrate through the crack and are deposited. This is a quick process.

- Autogenous healing depends on the width of the fissure. According to British standards, cracks less than 0.2mm wide are expected to heal automatically.

- Autogenous healing is influenced by water pressure. However, the type of cement and the type of water do not influence the formation of calcium carbonate.

- The formation of calcium carbonate is accelerated by the high temperature of the concrete, the increase in the pH value of the water and the drop in the CO content. 2 Particles in concrete.

Movement joints, expansion joints and control joints

Have Motion Joints , Expansion Joints and Expansion Joints Minimize cracks in some structures and avoid repairing cracks in concrete.

Different Types of Concrete Joints Available materials could be used to allow the concrete to move. If the structure is cast without joints, it may crack. If we repair the crack, it will reoccur. It is therefore necessary to allow the structure to behave freely.

In this type of structures we create expansion joints that allow movement joints or retraction joints that allow the formation of cracks.

These cracks or joints can be filled with a suitable, expensive and flexible sealant.

Other Methods for Repairing Cracks in Concrete

There are also other methods, such as crack grouting.

- Portland cement mortar

- Dry mortar method

Indirect method of repairing concrete cracks

There are other indirect methods to repair cracks. Instead of trying to repair the crack with sealant, the crack problem can be solved through alternative methods.

These types of repair methods are performed when the crack affects the load-bearing capacity of the components. Let's discuss each method in detail.

- Adding Additional Reinforcements

To withstand the tensile stress that occurs across the crack, additional reinforcements are inserted.

- preload

If there are structural cracks in the concrete, repairing them with structural mortar or epoxy mortar will not be sufficient. Therefore, additional reinforcement may be required.

If there are cracks in the slab or beams, we can apply post-tensioning to improve the load capacity. The following figure shows this repair.

- FRFP

FRFP is used to improve load capacity. This is mainly used in structural retrofit. If the concrete has cracks, this method can be used.

- Steel Beam Support

As with prestressing beams or slabs, we can use steel beams to support slabs or beams.

This is a common method of structural repair and can be used more efficiently when the structural element has lost its original capacity or when the structural capacity of the element needs to be increased.

- Provide additional support

If there are cracks in a structural element such as a beam or slab, if other elements allow it, we can use a support to reduce the stress on the cracked element.

Before supporting the cracked element, the structural element that transfers the additional load must be checked.

There are other related articles on concrete cracks and durability considerations. For more information, see the following articles.

Related articles

- Early thermal cracking (calculate R/F requirements)

- Influence of construction practices on the formation of cracks

- Formation of cracks in concrete (basics, types and causes)

- Physical reasons for cracks

- Basics of crack formation in immature concrete

- Types of Foundation Cracks, Why They Are Serious

- Basement Wall Cracks (A Detailed Study)

- What is concrete spalling – causes and repairs

- 20 factors that affect the durability of concrete

- Durability of concrete (requirements and problems)

- Concrete shaking (methods and correct procedure)

- 6 Factors That Affect Concrete Curing Time

- 11 Methods for Curing Concrete

- A detailed study of concrete (from scratch)

- Types of concrete shrinkage (detailed study)