1. Preamble

Cones are widely used in mechanical combination and assembly. When a designer specifies the taper size of an internal hole and requires machining an external taper to match it, the task can be challenging for operators because the taper of the external taper is difficult to control and measure.

At Panzhihua Iron and Steel Co., Ltd., the main factory area is equipped with C6120 and CA6140 machining equipment. When turning a cone with a small sliding plate, the minimum deflection accuracy of the lathe is 1 degree, which makes it difficult to meet the high precision requirements for machining the outer cone.

To meet the matching requirements, other measuring instruments are used to control the taper of the cone through a relative measuring method.

2. Manual turning of small short conical sliding plate

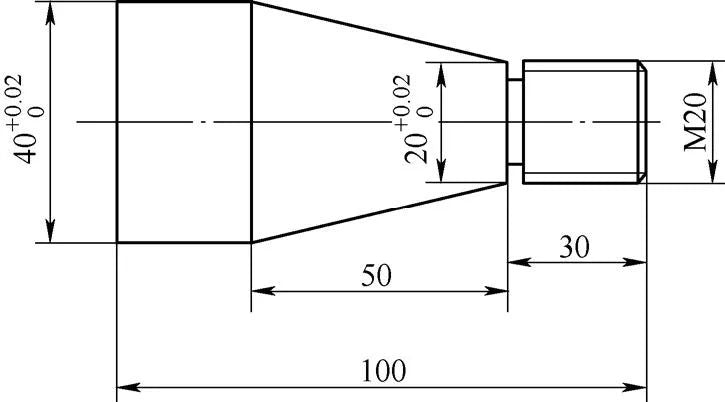

The parts shown in Fig. 1 are mainly composed of cone and thread.

Figure 1 pieces

The dimensions of the cone are represented in Figure 2, consisting mainly of:

Fig. 2 main dimensions of the conical part

- Cone angle α, which is the angle between two radial lines.

- Half cone angle α/2, which is the smallest sliding plate rotation angle during turning.

- Maximum end diameter D, commonly referred to as large end diameter.

- Minimum final diameter d, commonly referred to as small final diameter.

- Cone length L, which is the distance between the largest end diameter and the smallest end diameter along the axis.

When rotating a cone, the rotation angle of the smaller sliding plate is α/2, as illustrated in Figure 3.

Fig. 3 Schematic diagram of the rotation angle of the small sliding plate

The rotation angle of the smaller sliding plate, α/2, can be calculated using the trigonometric function relationship: tan(α/2) = (D – d)/(2L) = (40 – 20)/(2 x 50 ) = 0.2, resulting in α/2 = 11°20′.

The rotation angle of the smaller sliding plate is 11°20′, and its rotation angle is divided into increments of 1° without any subdivision into 20′. Measuring the angle with a universal angle ruler is a time-consuming and laborious process, and also results in an inaccurate cone angle. This leads to low part accuracy, making it difficult to meet the corresponding requirements.

To address this question, the shaded right triangle in Figure 2 (see Figure 4) was analyzed.

Fig. 4 Shaded right triangle

During taper turning, the path of the turning tool is from point C to point B. The length of this path can be calculated using the Pythagorean theorem (see Figure 5).

Fig. 5 Turning tool path length

During turning, the position of the tool tip relative to points B and C can be adjusted using the dial on the small slide plate.

When the tool moves a distance of 50.99mm, the distance between the tool tip and the lathe axis should measure 10mm, indicating that the turning taper angle is correct. Otherwise, the rotation angle of the small sliding plate is incorrect.

It is recommended to simulate the machining process before actually machining a cone.

To determine whether the rotation angle of the small slide plate is correct, first adjust the small slide plate so that the tool moves a distance of 50.99 mm, and then use a measuring tool to check whether the distance between the tool tip and lathe axis is 10mm.

This process can be repeated until the correct cone angle is achieved. The steps are illustrated in Figure 6.

Fig. 6 Schematic diagram of the specific operation method

(1) Start by rotating a section of the outer circle. The surface roughness should be low and there should be no taper along the length of the cylinder.

To ensure no taper, measure both ends of the cylinder with a micrometer and compare the dimensions. If they are the same, it means that the cylinder does not have a taper.

(2) Calculate the movement of the dial indicator and determine the side length BC using the Pythagorean theorem, which is the exact distance the small sliding plate needs to travel when the carriage is conical (BC = 50.99 mm).

(3) Rotate the small slide plate counterclockwise 11° to 12°, secure it with a screw, and then fix the dial indicator base to the tool holder on the small slide plate. Push the dial indicator contact into the outer circle (see Fig. 6).

(4) Align the small sliding plate with the zero position and point the dial indicator at the 10 mm scale position. Move the small sliding plate forward and the dial indicator contact will gradually extend.

If the small slide plate moves 50.99 mm and the dial indicator moves less than 10 mm, this indicates a small taper. In this case, loosen the locking screw to increase the taper.

If the small slide plate moves 50.99 mm and the dial indicator moves more than 10 mm, this indicates a large taper. Reduce the taper in this case.

If the small slide plate moves 50.99 mm and the dial indicator moves 10 mm, it means the taper is correct and turning can continue.

Precautions during adjustment are as follows :

(1) It is important to note that the outer circle used to determine taper should not have taper itself, as this will result in inaccurate measurements.

If the rotated outer circle has a taper, align it by pressing the dial indicator against the tailstock sleeve.

(2) To ensure accurate readings, make sure that the magnetic base of the dial gauge is firmly attached and that the connecting rod screw on the gauge frame is tightened without looseness.

(3) The measuring rod of the dial indicator must be perpendicular to the axis of the outer circle. If necessary, use a small square to correct perpendicularity and place the dial indicator contact as close as possible to the axis of the outer circle.

(4) It is recommended to use the longest possible measuring stroke of the dial indicator. Although a 10mm strip is common, a 30 to 50mm strip can also be prepared if necessary.

(5) This method can also be applied to machining an internal cone.

3. Automatic turning of long taper saddle tool

As depicted in Fig. 7, the rotation taper of the automatic saddle tool feed is achieved using the offset tailstock method.

Fig. 7 Automatic saddle tool feed taper turning

When moving the lathe tailstock laterally by a certain distance s, the axis of rotation of the part intersects with the axis of the lathe spindle, creating an included angle equal to half the part cone angle α/2.

As the base saddle is fed parallel to the main axis, it results in a taper in the workpiece.

This method is suitable for parts with a small taper (less than 3°) and long lengths.

3.1 Calculation of tailstock displacement

Tailstock displacement S ≈ L 0 tan( α/ 2) = L 0 (Dd) / (2L) or S = CL 0 / 2, where,

- S is the tailstock displacement (mm);

- D is the maximum diameter of the cone (mm);

- D is the minimum diameter of the cone (mm);

- L is the length of the cone (mm);

- l 0 is the total length of the part (mm);

- C is conical.

For example, when machining a tapered cylindrical part between two centers, with the given dimensions: D = 80 mm, d = 76 mm, L = 600 mm and L 0 = 1000 mm, the tailstock offset (S) can be calculated as follows form:

S = L 0 × (D – d) / (2 × L) = 1000 × (80 – 76) / (2 × 600) = 3.3 mm.

3.2 Tailstock compensation measurement

A dial indicator must be installed in the tool holder to measure the tailstock displacement, as shown in Fig.

Figure 8 Tailstock displacement measurement

3.3 T urn steps

Automatic tool feeding from the base saddle is used to machine a cone-shaped part. The workpiece is clamped as shown in Fig. 9. The rough turning of the outer cone is shown in Fig. 9.

Fig. 9 Clamping the workpiece

Fig. 10 Rough outer cone

Fig. 11 Complete the turning of the external cone

3.4C External Cone Turning Features with Automatic Bed Saddle Tool Feeding

- This method is suitable for machining external tapered parts with a small taper (less than 3°) and a long taper. However, it cannot be used for parts with large taper due to tailstock displacement limitations.

- By feeding the base saddle longitudinally automatically, the surface roughness (Ra) is reduced and the surface quality of the part is improved.

- The tip of the workpiece may be crooked in the center hole, resulting in uneven wear and poor contact.

- The part is fixed with double apexes and the chicken heart clamp transmits force, making it impossible to machine both the internal cone and the general external cone.

4. Conclusion

The two methods of machining a cone described above use trigonometric function relationships to calculate data, and then adjust the half-angle of the cone indirectly through the dial indicator, resulting in the machining of the outer cone and greater accuracy of the half-angle of the cone of the workpiece.

These methods have practical significance in machining external cones using standard machine tools.