What is laser welding?

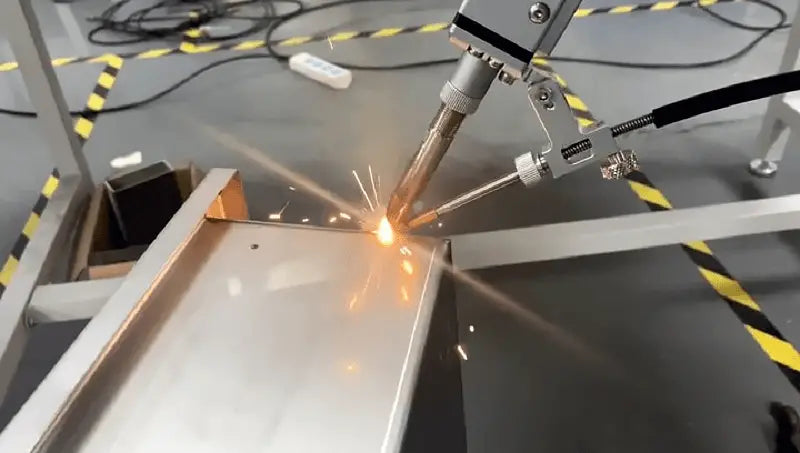

In short, laser welding involves melting the surface material of a part with a laser and joining it to another part made of the same material.

Laser welding is commonly used to weld metals or thermoplastics.

Various types of lasers can be used for this welding process.

Early applications of laser welding included solid-state lasers such as Nd:YAG and gas lasers such as CO2 lasers, which are still widely used today.

A laser is simply a highly concentrated beam of light that delivers significant energy.

The high power density of the lasers allows the part material to be melted in a controlled manner.

By exposing the material to the high-energy laser beam, the surface molecules gain enough energy to become more fluid.

When excited state molecules of the same substance come into contact and transition to a lower excited state simultaneously, they solidify and form molecular bonds.

Until the late 1990s, laser welding, like other laser-based technologies, was mainly used in laboratories and research institutions.

During this period, the concept of additive manufacturing, particularly 3D printing, gained popularity.

Although 3D printing using plastic resin or filament has been developed, there are few effective methods for applying the same process to metal.

The advent of laser welding technology has made the connection of powder metal as raw material fast and highly automated.

The widespread use of 3D printing has also spurred the development of laser welding technology, elevating this once experimental technology to a key player in the modern manufacturing industry.

Laser welding principle and process

The laser has extremely high energy, which when directed at the part, melts the irradiated portion, serving as the basis of laser welding technology.

It is important to note that laser is also a form of light, so the surface of the part should not be too smooth to reduce laser reflection.

The laser only reaches one point on the part, causing that area to reach a high temperature and melt.

Once the laser action stops, the locally molten metal quickly solidifies.

Laser welding can be classified into pulsed laser welding and continuous laser welding based on the output mode of the laser beam.

Furthermore, laser welding can be divided into thermal conductivity welding and deep penetration welding based on the characteristics of weld formation.

The first one, using low laser power, long molten pool formation time and shallow fusion depth, is mainly used for welding small parts.

The latter, with high laser power density and fast metal melting speed in the laser radiation area, results in strong vaporization as the metal melts.

Laser welding can achieve welds with deep penetration and large depth-to-width ratios of up to 12:1.

During laser welding, the laser injects heat into the material through the spot, and the temperature increase rate of the material is very fast.

The material below the surface can reach a high temperature in a short amount of time.

The weld penetration depth can be controlled by adjusting the laser power density.

The laser beam can be redirected using mirrors, allowing us to weld parts of the part that are difficult to access using conventional welding methods.

A laser welding system typically employs a 1 to 4 kW CO2 laser.

The laser beam generated by the laser is transmitted through the light guide system and reflected and focused by a parabolic mirror.

The high-temperature beam, reaching 5,000 to 20,000 K near the focus, is emitted from the nozzle and directed to the metal plate joint, instantly melting the metal material.

As the laser beam advances, the molten metal solidifies, forming a weld and connecting the two separate metal plates as one.

Gas lasers can be used for continuous welding, making them suitable for welding low-alloy steel, stainless steel, nickel, titanium, aluminum and other metals and alloys with thicknesses between 0.12 and 12 mm.

With solid-state laser welding, the small output energy (1 to 50 J) and short laser pulse duration (<10 ms) enable weld joints as small as tens of microns.

It can be used for spot welding and continuous spot welding of metal sheets with a thickness of less than 0.5mm, as well as butt welding of metal wires with a diameter of less than 0.6mm.

It is also suitable for welding valuable components of miniature, precise, densely arranged and heat-sensitive instruments.

The type of joint in laser welding is the same as in traditional welding.

What are the welding methods of laser welding machine:

1. Resistance welding

Resistance welding is used to weld thin metal products by clamping the welded part between two electrical electrodes, melting the surface in contact with electrical current to create a weld based on the heat resistance of the part.

This welding method may cause deformation of the product part as it is welded on both sides of the connector.

In contrast, laser welding is only carried out on one side, thus minimizing the risk of deformation.

Resistance welding requires frequent maintenance to eliminate metal oxides and other materials adhered to the product part.

On the other hand, when laser welding a reinforcement connector made of thin metal material, it does not touch the product part.

Additionally, laser welding allows light to enter areas that cannot be welded by basic welding, resulting in a faster welding speed.

2. Argon arc w and meet

The use of energy-free and maintenance-free steam to weld thin product parts is common.

However, the welding rate of this method is relatively slow, and the thermal bonding is much higher than laser welding, which can easily cause deformation.

3. Plasma arc welding

The speed of arc welding is similar to that of argon arc welding, but it is slower than that of argon arc welding.

4. Electron beam welding

Electron beam welding relies on a beam to accelerate high-energy, high-density electrons to collide with the product part. The main disadvantage of this method is that it requires high vacuum conditions to prevent electron scattering.

The machines and equipment involved are complex and the specifications and appearance of the welds are limited by the vacuum system.

Furthermore, the quality of butt weld installation must be strictly controlled.

Electron beam welding without a vacuum pump is possible, but the welding quality is often poor due to electron scattering, which affects the overall effectiveness.

Additionally, electron beam welding can introduce magnetic drift and X-ray problems. Electronic devices can be affected by electromagnetic field drift, causing malfunction or damage.

To solve this problem, parts for electron beam welding products must be welded within a magnetic field. In contrast, laser welding does not require a vacuum system or demagnetization of the product part prior to welding.

It can be carried out in air, making it suitable for production line operation or for welding permanent magnet materials.

Advantages and Disadvantages of Laser Welding

When examining the advantages and disadvantages of laser welding technology, it is useful to compare it with traditional welding methods such as gas shielded welding and argon arc welding.

These classic welding methods are still widely used in the manufacturing industry, and it will take some time for laser welding to fully replace them.

The advantage:

Laser welding is particularly suitable for automated manufacturing. Although it has been widely used in 3D printing, it can also be applied to the automation of traditional welding tasks.

Automatic welding offers several benefits to manufacturers, such as greater convenience, greater product accuracy, and more stable quality.

Automated systems are also much faster than manual welders, and traditional welding still requires a large number of welders.

Wide range of compatible materials

In traditional welding, such as argon arc welding, converting from one material to another involves adjusting the flame temperature and arc resistance.

The working principle of the laser is similar in this aspect. The laser can adjust its power to suit various materials, providing a distinct advantage.

With preset parameters for different materials, laser welding is more convenient than other welding methods.

Thanks to its high power density, laser welding can weld materials that are difficult to weld using other technologies.

Laser welding can be applied to a wide range of materials, including supermetals such as titanium and carbon steel.

In terms of power density, the only welding technology that can match laser welding is electron beam welding.

Fast heating rate

Another advantage of high power density lasers is their ability to melt materials more quickly than flame or arc welding. This results in faster welding speeds and stronger welds.

The penetration depth in laser welding can be controlled by adjusting the laser power.

Laser pulses can be applied to virtually any material to prevent damage to both materials and equipment.

Joints with complex geometry can be welded

A unique feature of laser welding is its ability to weld over greater distances than other welding methods.

Laser welded joints do not need to be close to the material being welded to provide the energy required for welding.

This provides more space for the operation of the part and makes it possible to weld parts with complex geometries.

High security

Laser welding machines are typically fully automatic and have an enclosed workspace. This means that personnel are no longer exposed to high temperatures and particles during welding.

At this point alone, it is worth investing in a laser welding machine. Any technology that can improve workplace safety and keep people out of unnecessary danger is worth considering.

Disadvantages:

There is a risk of cracking when the metal cools quickly .

Anything that heats up quickly also cools down quickly. The same applies to laser welding. The localized transmission of energy through the laser means that joints can be welded quickly.

However, this also means that the heat in the weld is quickly dissipated through the material, which leads to a significant build-up of thermal stress.

Only some materials can prevent cracking or damage due to this.

Carbon steel is a typical example, as it is prone to embrittlement when cooled too quickly.

One-time equipment cost investment is high

This may be the biggest obstacle to the wide application of this technology – the price of laser welding machines is expensive. This is more obvious than gas shielded welding and argon arc welding.

Traditional welding requires skilled welders, but does not necessarily require expensive equipment.

Laser welding overturns the idea that the equipment is expensive, but operation does not require many skills.

With large-scale production, laser welding equipment will mature along with the industrial chain. Just like in the LED lighting industry, the price will become more affordable and widely used.

Traditional welding can complete its mission and become part of history.

What is TIG welding?

Welding protected with tungsten inert gas is known as TIG welding. It is a welding method that uses the arc generated between the tungsten electrode and the workpiece to heat and melt the base metal and filler wire (if filler wire is used) under the protection of an inert gas.

During welding, shielding gas is continuously sprayed from the welding gun nozzle to form a protective layer of gas around the arc, isolating the air and preventing its harmful impact on the tungsten electrode, the molten pool and the adjacent zone affected by the heat, in order to obtain high quality welds.

The shielding gas can be argon, helium or an argon-helium mixture.

Related Reading: MIG vs TIG Welding

TIG Welding Overview

Tungsten inert gas arc welding, also known as TIG welding, is an arc welding method that uses external gas as a shielding medium. Its advantages include good visibility of the arc and weld pool and easy operation.

Additionally, there is little or no slag produced, which eliminates the need for slag removal after welding. However, special windproof measures need to be taken during outdoor operations.

Gas shielded welding can be divided into two types based on whether the electrode is melted during the welding process: gas shielded welding with a non-melting electrode (tungsten electrode) and gas shielded welding with a non-melting electrode (tungsten electrode). Fusion.

The first includes tungsten inert gas welding, plasma arc welding and atomic hydrogen welding. Atomic hydrogen welding is rarely used in production at present.

In special applications, a small amount of hydrogen may be added.

Tungsten argon arc welding is commonly called argon arc welding, and tungsten helium arc welding is called helium arc welding.

Due to the high price of helium, tungsten argon arc welding is more widely used in industry than helium arc welding.

TIG welding classification

TIG welding is divided into manual welding, semi-automatic welding and automatic welding according to the operation mode.

During manual TIG welding, the movement of the welding gun and the addition of filler wire are completely manually operated.

During semi-automatic TIG welding, the movement of the welding gun depends on manual operation, but the filler wire is fed automatically by the wire feed mechanism.

During automatic TIG welding, if the workpiece is fixed and the arc moves, the welding gun is installed on the welding cart.

Cart ride and filler wire can be added by cold wire or hot wire.

Hot wire refers to the increase in deposition speed.

In some cases, such as plate welding or backing pass, sometimes it is not necessary to add filler wire.

Among the above three welding methods, manual TIG welding is the most widely used, while semi-automatic TIG welding is rarely used.

Advantages and disadvantages of TIG welding

Advantage

- Argon can be effectively isolated from the surrounding air. It itself is insoluble in metal and does not react with metal. In the TIG welding process, the arc can also automatically remove the oxide film from the surface of the workpiece. Therefore, it can successfully weld non-ferrous metals, stainless steel and various alloys with easy oxidation, nitriding and strong chemical activity.

- The tungsten arc is stable and can burn stably even under a small welding current (< 10A). It is especially suitable for welding thin sheet and ultra-thin sheet materials.

- The heat source and filler wire can be controlled separately, so the heat input is easy to adjust and can be welded in multiple positions. It is also an ideal method for carrying out one-sided welding and two-sided flowering.

- Since the filler wire does not pass through the arc, there will be no spatter and the weld formation is beautiful.

Disadvantage

- TIG welding has a shallow fusion depth, low deposition speed and low productivity.

- The tungsten electrode used in TIG welding has a low current-carrying capacity. Excessive current will cause the tungsten electrode to melt and evaporate, and its particles may enter the molten pool and cause slag (tungsten inclusion) pollution.

- Inert gases such as argon and helium are more expensive and the production cost is higher compared to other arc welding methods such as manual arc welding, submerged arc welding and CO2 gas protected welding. TIG welding can be used to weld almost all metals and alloys, but due to its high cost, it is usually used to weld non-ferrous metals such as aluminum, magnesium, titanium and copper, as well as stainless and heat-resistant steel. steel. Welding is difficult for metals with low melting points and easy evaporation, such as lead, tin and zinc. From a productivity point of view, the thickness range of the plate welded by TIG welding should be less than 3 mm.

For some important thick-walled components, such as pressure vessels and pipes, made of black and non-ferrous metals, TIG welding is sometimes used to ensure high welding quality.

Argon tungsten arc welding is used in root penetration weld bead connection, all position welding and narrow gap connection.

Laser welding vs argon arc welding

| Category/mode | Argon Arc Welding | laser welding |

| Deformation | Easy to deform | Slight deformation or no deformation |

| Aesthetic grade | Ugly and needs repeated polishing | The appearance is smooth and can be treated lightly |

| Weld point size | Large soldering point | Fine welding spot and adjustable spot |

| Shielding gas | Argon | Argon |

| Heat input | Elevated temperature | Low fire |

| Machining precision | Generally | Necessary |

| Processing hours | Late | Little time consuming |

| Security | Ultraviolet light, radiation hazard | T exposure to light, almost no harm |

| Perforation degree | Easy drilling | Not easy to pierce |

| Degree of automation | Very low | Generally |

C feed speed

Spot welding machine and automatic welding are simply used for classification.

The welding operation of a laser spot welding machine is simple and fast.

The operation of meltless electrode argon arc welding is relatively difficult and requires consumables, so the welding speed is relatively slow.

The welding speed of an automatic laser welding machine and an automatic MIG welding machine is not much different because MIG welding still needs molten wire, so the welding speed will be a little slower than that of a machine automatic laser welding.

Welding depth

A laser welding machine is used to melt welding materials using a laser, but laser deep welding is not its strong point. It's not that deep laser welding is not good, but the cost is very high.

For example, if you need to weld a 2.0mm stainless steel plate, you would need to use at least a 500W fiber optic transmission laser welding machine, and the price would be around 100,000.

Although a general argon arc welding machine can weld such a thick stainless steel plate, the price is only a few hundred, and automatic argon arc welding costs twenty or thirty thousand.

Therefore, it is not economical to use a laser welding machine if deep penetration is required to weld thick materials.

Welding effect

The appearance of welding from a laser spot welding machine is more beautiful than that of argon arc welding with a non-melting electrode.

The welding appearance of an automatic laser welding machine is similar to that of an automatic argon arc welding machine, and the laser welding of thin materials is better.

In terms of welding firmness, as long as the power of the laser welding machine is large enough, it can weld firmly, which is comparable to argon arc welding.

However, the heat of the laser welding machine is more concentrated and the thermal deformation of the material is smaller, so the laser welding machine has more advantages in welding thin-walled materials.

In terms of precision, the precision of the laser welding machine is higher, and the subsequent welding with a laser welding machine basically requires no processing, which saves time and effort.

Difficulty of operation

Operating a laser spot welding machine is much less difficult than meltless electrode argon arc welding.

In fact, argon arc welding requires skill and is prone to error, but laser welding is much simpler and the operation is more straightforward.

Even if there are errors, they are not significant.

The operation of automatic laser welding and automatic argon arc welding is not difficult. Both require computer control.

Summary

For welding thin-walled materials, it is better to use a laser welding machine than welding thick materials.

If there are no high requirements for welding speed and accuracy, it is more economical to use an argon arc welding machine.

However, if cost is not a concern, it is better to use a laser welding machine.

Comparison Between Portable Laser Welding and Argon Arc Welding

Power consumption comparison:

Compared with traditional arc welding, the portable laser welding machine can save about 80%~90% of electrical energy and reduce the processing cost by about 30%.

Welding effect comparison:

Portable laser welding can complete the welding of different steels and metals. It has a fast welding speed, small deformation and a small heat-affected zone.

The welds must be beautiful, flat and free or with few pores and contamination. Portable laser welding machines can perform micro open parts and precision welding.

Comparison of subsequent processes:

During manual laser welding, the heat input is low and the deformation of the workpiece is small, which can result in a beautiful welding surface without or just simple treatment (depending on the welding surface effect required).

Manual laser welding machines can greatly reduce the labor cost of the extensive polishing and leveling process.

Advantages of portable fiber optic welding machine over traditional argon arc welding

| Item | Portable Optical Fiber Laser Welding | Traditional argon arc welding |

| Employment cost | The operation is simple, ordinary people start in half an hour, and the employment cost is low | Recruitment is difficult, salaries are high and employment costs are high |

| Personal injuries | Single wavelength beam pure energy, low indirect radiation, only need protective glasses to filter strong light | Occupational illness, serious physical injuries |

| Efficiency | The speed is fast, the efficiency can reach 3-8 times that of argon arc welding, and the linear welding speed can reach more than 10 cm/s | Slow speed and low efficiency |

| Thermal deformation | Energy concentration and little influence of thermal deformation | Great thermal influence and deformation |

| Weld quality | The solder is fine and beautiful, the solution pool is deep, and the strength is high | The weld is rough and irregular, requiring secondary grinding and polishing |

| Weldable material | Very thin materials can be welded, such as 0.05mm stainless steel | Do not weld very thin materials |

| Learning difficulty | Ordinary people can start in half an hour, and inexperienced workers can also start | Professional welders are required and the technical limit is high |

| Consumables | Can be welded with filler wire or without welding wire | Consumables, welding wire required |

| Weld damage | The solder is nice and thin, the solution pool is uniform, and the consistency is good. | It is easy to weld if there are pores |

Compared with traditional argon arc welding, portable fiber optic welding machine has disadvantages

| Item | Portable Optical Fiber Laser Welding | Traditional argon arc welding |

| Ability to fill in gaps | Weak, our company adopts oscillating welding, which can fuse the gap of 0.3-0.5mm at most, and adopts wire feeding welding, which can fuse the gap of more than 1mm at most | Strong, insensitive to part gap, large gap can be welded through filler |

| Equipment price | Expensive equipment | Cheap equipment |

| Volume weight | Relatively large volume and weight | Small size and light weight |

| Thick plate welding | It is not conducive to welding thick plate materials. The penetration capacity of the 1000 Watt molten pool is about 3 mm and that of 1500 Watt is about 4 mm. | Welding thick plate materials has advantages, which can accumulate and fill the welding solution set and can adapt to welding thicker materials |

Advantages of portable fiber optic welding machine over traditional argon arc welding

| Item | Portable Optical Fiber Laser Welding | Traditional argon arc welding |

| Employment cost | The operation is simple, ordinary people start in half an hour, and the employment cost is low | Recruitment is difficult, salaries are high and employment costs are high |

| Personal injuries | Single wavelength beam pure energy, low indirect radiation, only need protective glasses to filter strong light | Occupational illness, serious physical injuries |

| Efficiency | The speed is fast, the efficiency can reach 3-8 times that of argon arc welding, and the linear welding speed can reach more than 10 cm/s | Slow speed and low efficiency |

| Thermal deformation | Energy concentration and little influence of thermal deformation | Great thermal influence and deformation |

| Weld quality | The solder is fine and beautiful, the solution pool is deep, and the strength is high | The weld is rough and irregular, requiring secondary grinding and polishing |

| Weldable material | Very thin materials can be welded, such as 0.05mm stainless steel | Do not weld very thin materials |

| Learning difficulty | Ordinary people can start in half an hour, and inexperienced workers can also start | Professional welders are required and the technical limit is high |

| Consumables | Can be welded with filler wire or without welding wire | Consumables, welding wire required |

| Weld damage | The solder is nice and thin, the solution pool is uniform, and the consistency is good. | It is easy to weld if there are pores |

Disadvantages of portable fiber optic welding machine compared to traditional argon arc welding

| Item | Portable Optical Fiber Laser Welding | Traditional argon arc welding |

| Ability to fill in gaps | Weak, our company adopts oscillating welding, which can fuse the gap of 0.3-0.5mm at most, and adopts wire feeding welding, which can fuse the gap of more than 1mm at most | Strong, insensitive to part gap, large gap can be welded through filler |

| Equipment price | Expensive equipment | Cheap equipment |

| Volume weight | Relatively large volume and weight | Small size and light weight |

| Thick plate welding | It is not conducive to welding thick plate materials. The penetration capacity of the 1000 Watt molten pool is about 3 mm and that of 1500 Watt is about 4 mm. | Welding thick plate materials has advantages, which can accumulate and fill the welding solution set and can adapt to welding thicker materials |

Table 3: Portable laser welding has obvious advantages over traditional argon arc welding

| heat effect | subsequent treatment | plate requirements | requirements for workers | welding speed | availability of consumables | |

| Lone glow of argon | excellent | to need | Thickness > 1mm | High, generally requires professional technicians (assuming professional technicians' salary is 10,000 yuan/month) | slow | Yes (flux, solder wire) |

| Portable laser welding | Tiny | unwanted | Thickness <3mm | Ordinary and low-level workers can start after simple training (assuming the salary of ordinary workers is 4,000 yuan/month) | It is 2 to 10 times greater than argon arc welding | anything |

What would you choose between laser welding machine and traditional argon arc welding machine?

Nowadays, there are still some disputes between traditional argon arc welding and laser welding. The pace of technological advancement is unpredictable.

If argon arc welding operators who have been working for more than ten years start using laser welding, they may face some difficulties and may not be suitable for the new technology.

Both welding methods have their own advantages and disadvantages. Depending on the current industrial demand, we should choose the suitable welding method.

First of all, speaking of cost, the price of a traditional argon arc welding machine is about 2000 to 5000 yuan, which can be accepted by large and small factories.

The gun head is small, light and compact, and easy to carry, making it convenient to work on site.

However, the welding speed is slow, the efficiency is low, the heat-affected area is large, the solder joint is large and subject to deformation.

Furthermore, the requirements for operators are high and they must undergo professional training and have long-term practical experience.

There is also a certain amount of damage caused by radiation to the human body, which makes it difficult to recruit welders. Experienced welders are particularly difficult to find.

On the other hand, the relative price of a laser welding machine is high, about 50,000-100,000 yuan, and the machine is large. It is suitable for batch processing at specific points.

The welding speed is fast and the efficiency is high, which is 5 to 10 times that of traditional welding.

The spot size is adjustable and the welding effect is uniform and beautiful without deformation. The operation is simple, with few requirements for welders who can be trained in about ten minutes.

Wrap it up

Through our comparison, I believe you have a good knowledge about laser welding and argon arc welding.

Which would you choose?

Please leave a message in the comments area and tell us what you think.