The angle of a lathe tool is a crucial parameter that affects the cutting effect, including rake angle, clearance angle, feed angle, secondary feed angle and blade inclination angle.

- The rake angle refers to the angle between the tool and the workpiece contact surface, which influences the cutting force and the quality of the cutting surface.

- The clearance angle is the angle between the rear surface of the tool and the base, mainly affecting the tool's durability and heat dissipation conditions.

- The lead angle is the angle between the main cutting edge of the tool and the axis of rotation of the workpiece, affecting the distribution of cutting force and depth of cut.

- The secondary rake angle refers to the angle between the secondary cutting edge and the primary cutting edge, impacting the machined surface roughness and tool strength.

- The blade inclination angle is the angle between the tool edge and the workpiece rotation axis, affecting the chip ejection direction and machining quality.

When choosing the tool angle, consider the rigidity of the turning process system consisting of lathe, fixture and tool, as well as the geometric shape and material characteristics of the part being processed.

For example, when the rigidity of the system is good, the angle of attack should be small to increase tool life, improve heat dissipation conditions and surface roughness. When machining steps, the rake angle is generally 90°, while for parts cut in the middle, the rake angle is generally 60°.

Furthermore, the choice of incidence angle is influenced by the material to be processed. For example, when cutting plastic metals, the clearance angle is larger, while for brittle metals or materials with high toughness, the clearance angle is smaller.

The article delves into the various factors that influence the selection of each angle, such as the hardness of the material to be cut, the type of machining operation and the rigidity of the turning process system. It also explains the importance of the three reference planes used to determine and measure the geometric angle of the lathe tool.

Whether you're a seasoned professional or a beginner looking to improve your metal cutting skills, this article is a must-read. So, grab your lathe tools and get ready to take your machining operations to the next level!

When cutting metal, the angle of the tool plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the workpiece.

Lathe Cutting Tool Angle Selection Basics

Importance of angle selection

When working with a lathe, selecting the appropriate tool angle is crucial to getting the results you want. The angle you choose will greatly influence part accuracy, material removal rate, and overall process efficiency. A well-selected angle will also contribute to the durability of the cutting tool, saving time and reducing costs.

Types of cutting tools

There are several types of cutting tools used in lathe operations, including:

- Turning tools : They are used to remove material from the external diameter of a part, generating a cylindrical shape.

- Facing Tools : Used to cut material into the end of a workpiece to create a flat surface.

- Flat tools : Essential for enlarging existing holes in a part.

- Cutting tools : Designed to cut or separate a portion of the workpiece from the original material.

Tool angle geometry

The geometry of tool angles plays an essential role in determining the performance and life of a cutting tool. Some critical angles to consider are:

- Inclination angle : This angle influences chip formation, cutting force and temperature generation. A positive rake angle can reduce cutting force and facilitate chip formation, while a negative rake angle can provide a stronger cutting edge suitable for harder materials.

- Clearance Angle : Clearance angles are essential to prevent friction between the workpiece and the tool. Insufficient clearance can result in increased wear and heat generation.

- Lead angle : Lead angle is the angle between the cutting edge and the surface of the workpiece. It affects the direction of forces, chip thickness and contact length between the tool and the workpiece. A larger angle of attack can result in thinner chips, reducing cutting forces, but can also compromise the quality of the surface finish.

The selection of tool angles will depend on factors such as the material being cut, the type of lathe operation performed, and the desired result for the part. By understanding these basic principles, you can make informed decisions to optimize your lathe cutting process.

Lathe tool cutting part composition

The cutting part of a lathe tool consists of the rake face, main flank face, secondary flank face, main cutting edge, secondary cutting edge and tool tip.

- Rake face: The surface through which chips flow into the tool.

- Leading flank face: The surface of the tool that interacts with and opposes the machined surface on the workpiece.

- Secondary flank face: The surface of the tool that interacts and opposes the machined surface on the workpiece.

- Main advantage: The intersection line between the tool rake face and the main flank.

- Secondary cutting edge: The line of intersection between the tool rake face and the secondary flank.

- Tool Tip: The intersection of the primary cutting edge and the secondary cutting edge. The tip of the tool can be a small curve or a straight line, called the tip of the rounding or chamfering tool.

Auxiliary Plane for Measuring Lathe Cutting Tool Angle

To determine and measure the geometric angle of the lathe tool, three reference planes must be selected. These three reference planes are the cutting plane, the base plane, and the perpendicular plane.

1) Cutting plane

A plane that intersects at a designated point on the main cutting edge and is perpendicular to the base plane of the shank.

2 ) Base plan

A plane that passes through a selected point on the main cutting edge and is parallel to the base surface of the shank.

3) Orthogonal plane

A plane that is perpendicular to the cutting plane and perpendicular to the base plane.

It can be seen that these three coordinate planes are perpendicular to each other, forming a rectangular spatial coordinate system.

Main Geometric Angles and Lathe Tool Selection

1) Principle of tilt angle selection (γ0)

The size of the rake angle is a crucial factor in balancing the durability and sharpness of the cutting tool.

When determining the rake angle, the first consideration should be the hardness of the material being cut.

For materials with high hardness, a smaller inclination angle is preferable, while for softer materials, a larger angle is appropriate.

Furthermore, the type of machining operation also influences the choice of rake angle.

For rough machining, a smaller angle is preferred, while a larger angle is used in finishing operations. A tilt angle between -5° and 25° is typically selected.

Typically, the rake angle (γ0) is not predetermined in lathe tool manufacturing. Instead, this is achieved by grinding a chip discharge groove in the tool.

This groove, also known as chip breaker groove, serves to break chips without curling, control the direction of chip flow to maintain the precision of the machined surface, reduce cutting resistance and extend tool life.

2) The principle of posterior angle selection (α0)

Firstly, the type of machining must be considered. In finishing machining, the back angle should have a large value, while in rough machining it should have a small value.

Secondly, the hardness of the material to be processed must be taken into account.

If the material to be machined is hard, the main back angle should have a small value to improve the firmness of the cutting head.

On the other hand, if the material is soft, the back angle may have a larger value. The back angle must not be 0° or negative and is generally chosen between 6° and 12°.

3) Cutting edge angle selection principle (Kr )

Firstly, the rigidity of the turning process system consisting of lathes, accessories and tools must be considered.

If the rigidity of the system is good, the entering angle should be a small value, which will increase the tool life of the lathe, improve heat dissipation conditions, and result in better surface roughness.

Secondly, the geometry of the part to be processed must be taken into account. When processing steps, the cutting edge angle should be 90°.

For parts cut in half, the cutting edge angle is generally 60°. The cutting edge angle is generally between 30° and 90°, with the most commonly used angles being 45°, 75° and 90°.

4) The principle of selecting the secondary deflection angle (Kr')

Firstly, the lathe tool, workpiece and clamp must have sufficient rigidity to reduce the secondary deflection angle, otherwise a larger value must be considered.

Second, consider the nature of the processing.

In finishing machining, the secondary deflection angle should be 10° to 15°, while it should be around 5° for rough machining.

5) The principle of tilt angle selection (λS)

It mainly depends on the nature of the machining process. During rough machining, the workpiece has a significant impact on the lathe tool.

In finishing machining, when λS is less than or equal to 0°, the impact force of the workpiece on the lathe tool is minimum.

When λS is greater than or equal to 0°, it is generally considered a value of 0°. The tilt angle is normally selected between -10° and 5°.

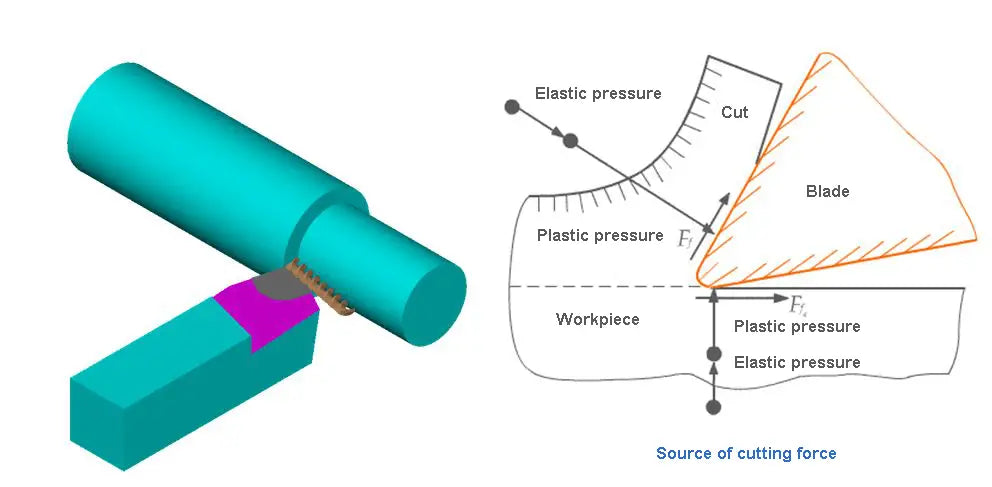

What is the specific impact of lathe tool angles on cutting forces and cutting surface quality?

The influence of lathe tool angles on cutting forces and cutting surface quality is mainly reflected in the following aspects:

Rake angle: The size of the rake angle directly affects the sharpness of the cutting edge and the cutting force. An increased rake angle can improve the sharpness of the cutting edge, thereby reducing cutting force and making cutting easier. Simultaneously, a larger rake angle helps improve chip evacuation, reduces cutting deformation and improves the quality of the machined surface. However, when the rake angle is too large, the strength of the cutting edge decreases, causing the tool tip to wear faster and the cutting force to increase.

Clearance angle: Clearance angle is the angle between the cutting face and the line perpendicular to the tool axis. It influences the resistance of the cutting edge and chip evacuation. An appropriate rake angle can increase tool durability and chip removal efficiency, but an excessively large rake angle can increase cutting force.

Lead angle: Lead angle affects chip shape and direction of cutting force. Different rake angles are suitable for different machining requirements such as roughing or finishing machining. For example, in rough face milling, a rake angle of 60° to 75° can significantly reduce the radial cutting force, improving vibration resistance and cutting stability.

Tip bevel angle: A larger tip bevel angle can reduce cutting forces and cutting temperature while increasing cutting edge life and surface quality. However, if the chamfer angle is too large, it may reduce the cutting edge entry angle. Chips can easily block the space between the tool and the workpiece, affecting machining results.

What are the best selection criteria for back angle when processing different materials?

The best selection criteria for back angle when processing different materials mainly depends on the material properties of the workpiece (such as hardness, plasticity, toughness, etc.) and the specific requirements of the machining process (such as rough machining or fine machining) . Here are the best selection criteria I summarized from my research:

When machining plastic materials, a larger back angle should be chosen. This is because plastic materials tend to deform and stick to the tool. A larger back angle helps reduce friction between the tool and the workpiece, thereby improving machining efficiency and surface quality.

When machining brittle or hard materials, a smaller back angle should be chosen. This is because brittle and hard materials are more prone to cracking. A smaller back angle can increase the strength of the cutting edge and prevent breakage during the machining process.

During fine machining, due to the smaller cutting thickness, a larger back angle must be chosen to ensure the quality of the machined surface. This makes the tool sharper, reduces wear and improves machining precision.

When machining materials that are prone to forming hardened layers, a larger back angle should also be chosen. This helps prevent hardened layers from forming and maintain tool sharpness.

For specific materials such as titanium alloys that have higher plasticity and toughness, a larger back angle should also be considered during machining to reduce machining difficulty and improve machining efficiency.

How is the influence of primary and secondary relief angles on the roughness of the machined surface quantified?

The influence of primary and secondary relief angles on the roughness of the machined surface can be quantified in several ways:

Impact of primary relief angle: The primary angle of relief (KAPR) is the angle between the main cutting edge of the tool and the surface of the workpiece. It affects chip thickness, cutting force and tool life. As the primary relief angle decreases, the chip thickness decreases. This chip thinning effect distributes the machined material over a larger part of the cutting edge, which can affect surface roughness.

Impact of secondary relief angle: The secondary relief angle mainly affects the roughness and quality of the machined surface. A smaller secondary relief angle can reduce surface roughness because it can increase tool tip strength, reduce vibration, and polish the machined surface.

However, reducing the secondary relief angle can easily cause vibration, so it needs to be determined based on the rigidity of the machine tool. Furthermore, it is common to reduce the surface roughness value by decreasing the secondary relief angle kr', although this may cause vibration in the tool.

Comprehensive consideration: Among the geometric parameters of the tool, the primary relief angle Kr, the secondary relief angle Kr' and the tool tip radius re have a significant influence on the surface roughness. When the primary and secondary relief angles are small, the height of the residual area on the machined surface is also small, thereby reducing the surface roughness. This indicates that by adjusting the size of the primary and secondary relief angles, the surface roughness can be controlled to a certain extent.

What are the specific case studies on the influence of tool rake angle on chip evacuation direction and machining quality?

The impact of the tool rake angle on the chip evacuation direction and machining quality can be observed mainly in the following aspects:

The positive or negative angle of inclination directly influences the direction of chip flow. When the rake angle is positive, the chip rotates counterclockwise and lengthens, forming an angle at its root with the transition surface, causing the chip flow to extend only toward the surface to be processed. This indicates that the rake angle design plays a vital role in controlling the direction of chip flow, especially in situations where it is necessary to reduce chip contamination on the workpiece surface.

In the oblique cutting process of C45 steel, the rake angle λs significantly affects the minimum uncut chip thickness (hmin) within the range of 0° to 60°. This finding was confirmed through theoretical analysis and experimental verification. This implies that the rake angle not only influences the direction of chip evacuation, but also has a direct impact on the material removal rate during the machining process.

During angle cutting, the chip flows out of the cutting edge in an inclined direction and produces a lateral curvature along the front face of the tool, forming a spiral chip discharge. This phenomenon is caused by the distribution of friction forces between the tool and the chip. This further proves the significant impact of rake angle on chip evacuation characteristics.

Adjusting the tilt angle can also affect the durability of the tool and the hardening degree of the workpiece. Increasing the tilt angle can lead to a drop in the temperature of the rear face of the tool, thereby reducing wear on the rear face of the tool. This means that by adjusting the rake angle, the tool life can be extended to a certain extent and the surface quality of the workpiece can be improved.

In a high rigidity system, how to adjust the lathe tool angle according to the geometry and material characteristics of the workpiece?

In high-rigidity systems, adjusting the lathe tool angle according to the geometric shape and material characteristics of the workpiece requires initial consideration of the tool's geometric parameters, including the main lead angle, relief angle, and approach angle.

These parameters significantly impact cutting deformation, cutting force, cutting temperature and tool wear, thereby affecting cutting efficiency, tool life, workpiece surface quality and machining cost. For example, adjusting the tool angles, particularly the main feed angle, relief angle and approach angle, can solve the problem of machine tool vibration and tool chatter.

For different part shapes and materials, selecting the appropriate tool shape is also crucial. For example, an 80-degree diamond-shaped blade is suitable for a wide range of applications, from rough machining to fine machining, while a 55- or 35-degree diamond-shaped blade is typically used for contour machining. In addition, the geometric shape of the tool must also consider factors such as the geometric shape of the workpiece, its material and surface quality requirements.

In practical operations, attention must also be paid to the size of the residual area left on the machined surface when the tool makes a forward movement in relation to the workpiece. Reducing the main rake angle, relief angle and increasing the tool nose radius can decrease the height of the residual area. This implies that when adjusting the tool angle, one must consider not only the geometric parameters of the tool, but also how these parameters impact physical phenomena during the cutting process, such as cutting force and cutting efficiency.

Adjusting the angle of the lathe tool according to the geometric shape and material characteristics of the workpiece requires comprehensive consideration of the geometric parameters of the tool (such as the main attack angle, relief angle and approach angle), selecting the appropriate tool shape and considering the interaction between the tool and the workpiece, as well as the physical phenomena during the cutting process. These adjustments can help improve machining efficiency, extend tool life, and ensure part machining quality.