1. Pre-Operation Inspection

1.1 Add appropriate lubricating oil and grease according to the machine lubrication chart.

1.2 Check that all electrical installations, handles, transmission parts, protections and limit devices are complete, reliable and flexible.

1.3 All gears must be in the neutral position and the belt tension must meet the requirements.

1.4 Do not place metal objects directly on the bed surface to avoid damaging it.

1.5 Make sure the part to be processed is free from mud and sand to prevent them from falling into the carriage and damaging the guide rails.

1.6 Before fixing the workpiece, it must undergo a test to ensure that everything is normal before assembling the workpiece.

2. Operating Procedures

2.1 Properly clamp the workpiece, turn on the lubricating oil pump first, and make sure the oil pressure meets the machine specifications before starting.

2.2 When adjusting the gearbox or suspended wheel, the power supply must be disconnected. After adjustment, all screws must be tightened and the wrench must be removed immediately. Perform a test without the workpiece.

2.3 After loading or unloading the workpiece, immediately remove the chuck key and any floating objects on the workpiece.

2.4 Adjust the tailstock, rocker arm and other machine parts to appropriate positions according to processing needs and tighten or clamp them.

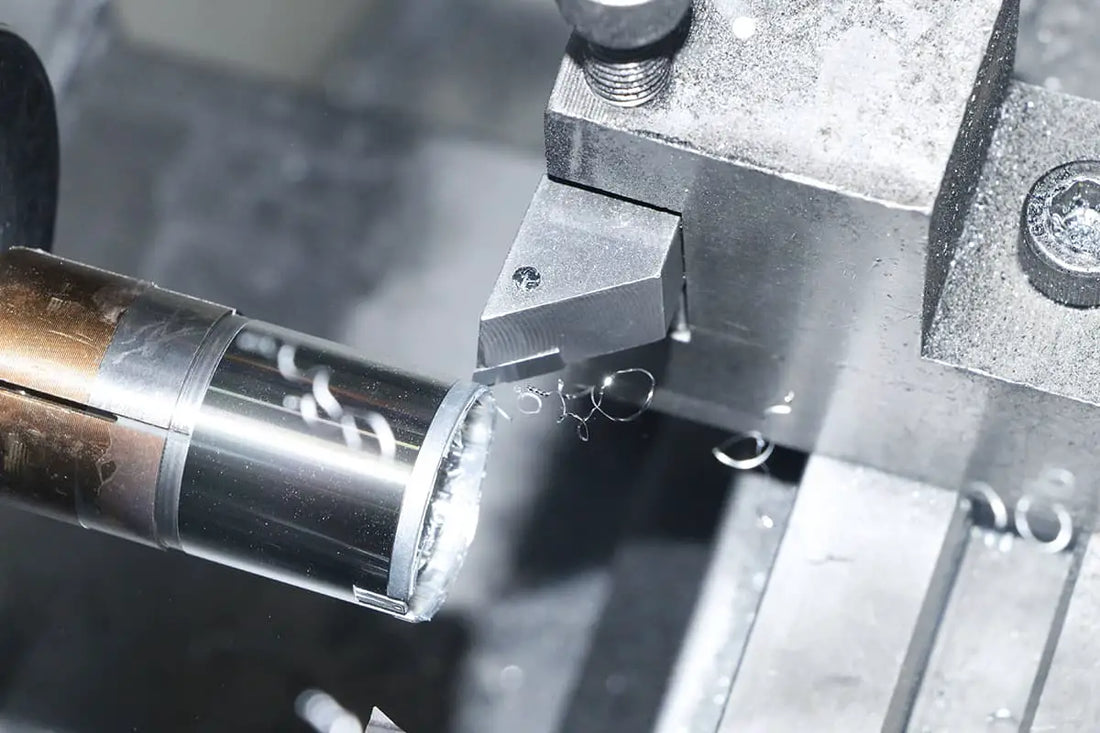

2.5 The workpiece, cutting tools and accessories must be securely fixed and the cutting force must extend to the workpiece before starting the machine.

2.6 When using a center frame or companion support, ensure that the center is properly adjusted and has good lubrication and contact with the support.

2.7 When machining long materials, the portion extending beyond the spindle must be kept within a reasonable range. If it is too long, a support rack must be installed and a warning sign must be hung.

2.8 When approaching the workpiece, the tool must be approached slowly to avoid impact. The speed of the car must be uniform during the back and forth movements. When changing tools, make sure there is adequate distance between the tool and the workpiece.

2.9 Clamp the cutting tool securely, and the length of the cutting tool protrusion should generally exceed 2.5 times the thickness of the tool.

2.10 When machining eccentric parts, suitable counterweights must be used to balance the center of gravity of the chuck and the cutting speed must be adequate.

2.11 When fixing workpieces that extend beyond the machine body, protective measures must be taken.

2.12 When adjusting the tool, do so slowly. When the tool tip is 40-60 millimeters away from the working area of the workpiece, switch to manual or mechanical feed, then engage rapid feed to make direct contact.

2.13 When using a file to polish the workpiece, the tool holder must be moved to a safe position. The operator must face the chuck, with the right hand in front and the left hand behind. It is prohibited to use a file to process parts with keyways or square holes.

2.14 When using sandpaper to polish the workpiece, the operator must hold both ends of the sandpaper as described above and polish. It is prohibited to use your fingers to hold the sandpaper to sand internal holes.

2.15 When using automatic feed, adjust the small tool holder to be level with the base to prevent the base from touching the chuck.

2.16 When cutting large or heavy parts or materials, leave sufficient machining margin.

3. Shutdown Procedure

3.1 Turn off the power and remove the workpiece.

3.2 Place all handles in the zero position and clean and tidy up tools and equipment.

3.3 Check the status of all protection devices.

4. Precautions during operation

4.1 Non-personnel are strictly prohibited from operating the machine.

4.2 It is strictly prohibited to touch the tools or any rotating parts of the machine during operation.

4.3 Use the emergency stop function correctly. After using the emergency stop button in an emergency, follow the machine's startup procedures and check everything again.

4.4 When using a foot-operated lathe, except as specified, use the foot instead of the hand to operate the guide rail, lead screw, and light rod handles of the lathe.

4.5 For parts with sand holes, tapered holes or keyways on the inner wall, use a triangular scraper to cut the inner hole according to the process requirements.

4.6 The pressure of compressed air or liquid of pneumatic or hydraulic chucks must meet the specified value before use.

4.7 When turning long, slender parts, if the length extending beyond both ends of the headstock exceeds four times the diameter, use a stable support, center frame or companion support for support. If you exceed the counterpoint, install protective devices and warning signs.

4.8 When cutting brittle metals or materials prone to chip splashing (including frontal swing), install protective shields and the operator must wear protective glasses.