History of the development of chipbreaker grooves

With the development of interchangeable cutting tool technology and powder metallurgy technology, chipbreaker grooves have become increasingly complex and diverse in their shapes and functions. In addition to the traditional straight, diagonal and curved edge grooves, various shapes of protrusions, depressions and curved grooves have emerged.

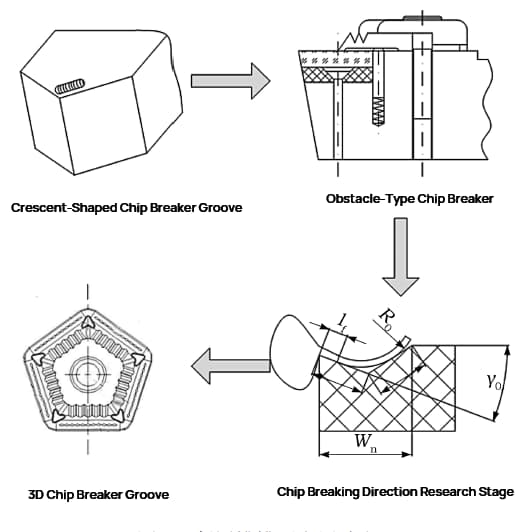

The development history of chipbreaker groove can be summarized into four stages: the crescent-shaped chipbreaker groove stage, the obstacle-type chipbreaker stage, the chip breaking direction research stage and the groove stage of the 3D chipbreaker, as shown in the figure below.

In the 1950s, the appearance of a crescent-shaped depression on the face of the tool during cutting facilitated chip breaking. Inspired by this, people would pre-grind a crescent-shaped depression-like groove on the face of the tool to facilitate chip breaking, or add an additional chip-breaking device on the face of the tool, which are often called traditional chipbreaker grooves and obstacles. chipbreaker type, respectively.

At that time, the theory of chip breaking was not yet fully developed, and people generally used the “trial and error method” to design groove shapes, which was very inefficient.

In the 1960s, groove shape design focused on analyzing, comparing and optimizing grooves for traditional chipbreakers and obstacle-type chipbreakers. The influence of chipbreaker groove shapes on chip shape and size has been studied extensively, allowing chip breaking to occur over a wide range of cutting conditions.

In the 1970s, with the maturity of molding technology, groove machining changed its traditional grinding wheel method, and the groove shape design became more complex and versatile. At this time, groove design mainly considered reducing the energy loss of chip flow and machining process, and typical groove structures such as inclined grooves and facet angle designs emerged.

In the late 1980s, the rapid development of complex 3D chipbreaker grooves greatly increased tool life and reliability compared with traditional 2D chipbreaker grooves, reduced machine and workpiece vibrations, reduced machining temperatures and improved machining quality of the part.

The 3D chipbreaker groove has a rich variety of shapes, mainly including two-stage grooves and wavy edges. Thanks to the development of 3D chipbreaker grooves, the application of CNC contour machining has also been continuously improved. For example, when turning a spherical part, a 3D chipbreaker groove tool can ensure high machining accuracy throughout the process.

Classification of chipbreaker groove shapes

Traditional chipbreaker grooves can be classified into three types: straight, arc-shaped and straight arc-shaped, as shown in the schematic diagram of groove structures below.

The chip breaking effect can be measured to a certain extent by the chip curvature radius. Furthermore, the smaller the curvature of the chipbreaker groove shape, the smaller the radius of curvature of the chip, the greater the deformation of the chip, and the more likely it is to break.

The straight arc-shaped chipbreaker groove is composed of a straight section and an arc section. The straight section is used to guide the chip outward, and the arc section at the end causes the chip to curl, which leads to deformation and breakage.

The smaller the diameter of the arc section, the easier the chip breaks.

The straight-line chipbreaker groove is formed by the intersection of two straight lines, and the bottom angle of the groove is the complementary angle of the chip wedge angle.

In the model shown in figure (b), the lower groove angle replaces the role of the lower arc radius of the groove R in the models shown in figures (a) and (c). That is, the chip will reach the back surface of the groove before the intersection of the two straight lines, and then directly curl and deform. The smaller the bottom angle of the groove, the smaller the curvature and radius of curvature of the chip and the more likely it is to break.

Compared with the previous two types, the arc-shaped chipbreaker groove has a relatively large front angle. The increase in face angle means that the chip's radius of curvature decreases and chip deformation increases, increasing the likelihood of chip breakage. Therefore, it is often used to cut highly ductile materials such as purple copper.

Furthermore, due to its full arc structure, the groove depth is relatively small and the chip flow is smoother, making it more practical in engineering applications.

Analysis of chipbreaker groove parameters

The basic structure of the chipbreaker groove is shown in the figure below.

This paper takes the straight arc-shaped chipbreaker groove as an example to illustrate the influence of the geometric parameters of the chipbreaker groove on the chip performance.

In the figure, br is the negative chamfer width, Wn is the normal groove width (referred to as groove width) of the chipbreaker groove of the main cutting edge, γ0 is the front angle of the chipbreaker groove, γ1 is the front angle of the negative chamfer, h is the height of the blade, and H is the depth of the chipbreaker groove (known as groove depth).

Changes in these parameters will directly affect the flute type and chip performance of the chipbreaker groove. Based on the literature, the following conclusions can be drawn:

1. Setting a negative chamfer can increase the strength of the cutting edge. The wider the negative bevel, the blunter the cutting edge and the greater the cutting force. If the negative chamfer width is too small, the cutting edge strength will be reduced, affecting tool life. Therefore, there is an ideal value for the negative chamfer width.

2. The greater the front angle of the chipbreaker groove, the smaller the chip curvature radius, the greater the chip deformation, and the easier it is for the chip to break.

3. Flute width and depth are the main factors affecting chip breaking. When designing the chipbreaker groove geometry, the influence of groove width and depth on chip breaking is interrelated. When selecting the geometric parameters of the channel type, the relationship between the width and depth of the channel is generally considered as a parameter.

Generally, if the groove width is too large, the chip will not be easy to break, while if the groove width is too small, it is easy to cause chip jamming. Therefore, a larger groove width can be used for rough machining, while a smaller groove width can be used for finishing. With the groove width determined, a smaller value should be selected for the groove depth.

4. The influence of blade height on chip performance is also affected by flute depth. With the same groove depth, reducing the blade height will increase the face angle, reduce chip deformation, reduce cutting force, and decrease the probability of chip breakage. However, increasing the blade height will increase obstruction of the groove back to the chip, increasing the likelihood of chip breakage and reducing blade edge strength.

5. The relief angle is the angle between the tangent of the rear groove and the front face of the tool. The greater the relief angle, the easier the chip will break.

In addition to the front angle of the chipbreaker groove having a significant impact on chip performance, other angle parameters also have some influence, among which the primary clearance angle and rake angle have the greatest influence.

The primary clearance angle mainly affects the thickness and width of the cut. When the primary rake angle increases, the chip becomes narrower and thicker and is more likely to break.

The rake angle mainly affects the direction of chip flow. When the rake angle is greater than zero, the chip flows toward the unprocessed surface and can be used for finishing. When the inclination angle is less than zero, the chip flows towards the processed surface, affecting the surface quality. Considering the size of the tool, the inclination angle is generally selected between 5° and 15°.

Classic chipbreaker designs and their characteristics

This article selects hard alloy cutting tools (0° back angle) from 8 companies with high market share in the current market (Mitsubishi, Kyocera, Sumitomo, Dege, Sandvik, Kennametal, Tungaloy and Walter). Based on their geometric shapes, nine basic types of slots and their design characteristics are summarized and analyzed below.

Linear type

Typical cutting tool with straight structure and flat bottom.

The negative rake angle and straight section in the middle ensure cutting edge strength, allowing for a larger front angle.

Typical cutting tool with straight, pointed tip and flat bottom.

The front angle is generally smaller to ensure the strength of the cutting edge. The height of the cutting edge is sufficient to facilitate chip breaking.

Typical cutting tool with straight double groove structure.

The double groove structure is used for contour turning.

Circular arc type

Typical cutting tool with single circular arc structure.

The circular arc structure organizes the front angle from large to small, while ensuring the strength of the cutting edge.

Typical cutting tool with double circular arc structure.

The circular arc structure. The convex surface at the rear of the groove provides elastic chip breaking, allowing a higher feed rate compared to rigid chip breaking.

Linear arc type

Typical cutting tool with straight-circular-straight structure.

The negative rake angle increases cutting edge strength, while a larger head angle ensures sharpness but may not lead to chip breakage. When the face angle, groove width and cutting edge height are constant, a larger width-to-depth ratio makes chip breaking easier.

Typical cutting tool with straight-circular structure.

Negative tilt angle, large front angle. When the face angle, groove width and cutting edge height are constant, a larger width-to-depth ratio makes chip breaking easier.

Typical cutting tool with circular-straight structure.

The front end of the groove is designed to be circular while ensuring cutting edge strength.

Typical cutting tool with straight-circular structure (double groove).

The convex back design of the groove provides elastic chip breaking, allowing a higher feed rate compared to rigid chip breaking. The double-slot structure is used for contour machining and is often used in precision machining.

Among the 9 basic slot types listed in the table above, 4 slot structures have been modified from previous designs to improve chip breaking performance. The 4 typical slot structures are shown in the following figure, with a classic example of each slot type listed:

a) The type of groove in Figure A is a straight circular structure (double groove). Compared with the traditional concave curved surface straight circular groove, this structure symmetrically adjusts the circular arc part of the groove, using it as a convex elastic chip breaking ring, allowing a higher feed rate compared with chip breaking rigid.

Using this type of groove, the contact area between the chips and the chip breaking groove in the cross-sectional direction is smaller. Furthermore, compared with the traditional concave curved surface chip breaking groove, the chip curl radius is smaller, making chip breaking easier.

In addition, the convex surface can increase the lateral curvature of the chips, resulting in greater deformation of the chips, making them easier to break.

b) The groove type in Figure B is a double circular arc structure. The characteristic of the double circular arc structure is that a small convex elastic chip breaking ring is placed at the rear end of the groove, and the front end of the circular arc structure groove type arranges the front angle from large to small.

Compared with the straight structure, considering that a small front angle will increase the deformation of chips and make the cutting easier to break, the circular arc structure at the front end of the groove type is more conducive to chip breaking. Therefore, it is not necessary to place a large convex snap ring to break chips at the back of the groove. Setting a small convex surface at the end can achieve similar effects.

c) The slot type in Figure C is a straight structure with a flat bottom. The traditional straight-edge bottom structure concentrates stress at the bottom, which affects the strength of the cutting edge. Changing it to a flat bottom structure can overcome the problem of low cutting edge strength.

Furthermore, as it is a flat-bottomed structure, a larger front angle can be defined, thus reducing cutting forces and temperatures. Therefore, this structure is more suitable for cutting plastic materials.

d) The groove type in Figure D is a straight double groove structure. The straight double slot structure has two slots and belongs to a double slot structure.

Whereas in rough machining, a large feed rate and depth of cut are required to ensure efficiency, while in precision machining, a small grooving width and adequate grooving depth are required to ensure good machining accuracy, The double flute structure is designed in such a way that the chips are broken in the first deep groove in precision machining and in the second groove in rough machining.

The advantage of this structure is its composite structure, which provides a wider machining range.

In addition to the designs mentioned above, there are many slot type designs with special structures. Additionally, more designs that are more suitable for specific situations can be added based on traditional slot shapes to make them easier to manufacture.

For example, in the design of a type of three-dimensional chip breaking groove, the cutting edge may be designed as a curve or a wave shape (such as Toshiba type 37 chip breaking groove and Toshiba type 37 chip breaking groove type PF from Sandvik).

Alternatively, the traditional concave curved surface chip breaking groove can be changed to a convex surface (such as Sumitomo's GH type chip breaking groove and Sandvik's MM type chip breaking groove) to achieve the breaking purpose elastic chip flow and reduced chip breakage during high feed rates. Friction reducing structures can also be used in the design.

This article provides two typical types of chip breaking grooves with special designs, as shown in the figure below.

Chip breaking performance evaluation

The chip curvature radius is a universal measure of the chip breaking effect.

Chip corrugation can take the form of 2D or 3D corrugation, with 2D corrugation mainly consisting of upward corrugation and sideways corrugation. Currently, there has been extensive research on the theory of 2D rising ripple.

For example, the predicted radius of curvature of straight-type and straight-arc type chip slots was examined. The corrugation of the straight type groove is illustrated in the diagram below:

Chip winding for a convex surface groove is illustrated in the diagram on the left below, and chip winding for a straight arc type groove is illustrated in the diagram on the right.

The formula for calculating the radius of curvature of chips is very complex and will not be explained in detail here.

The chip slot is based on changing the chip's radius of curvature to improve chip performance while using the chip's radius of curvature to measure chip performance.

After comparing with the empirical formulas summarized by previous researchers, the original text concludes that the chip curl radius is proportional to the groove width and inversely proportional to the face angle, that is, smaller groove widths and larger face angles are advantageous for chip breaking.