This article provides an overview of the development, current research status and future trends of ultrasonic machining technology, with a focus on its industrial applications.

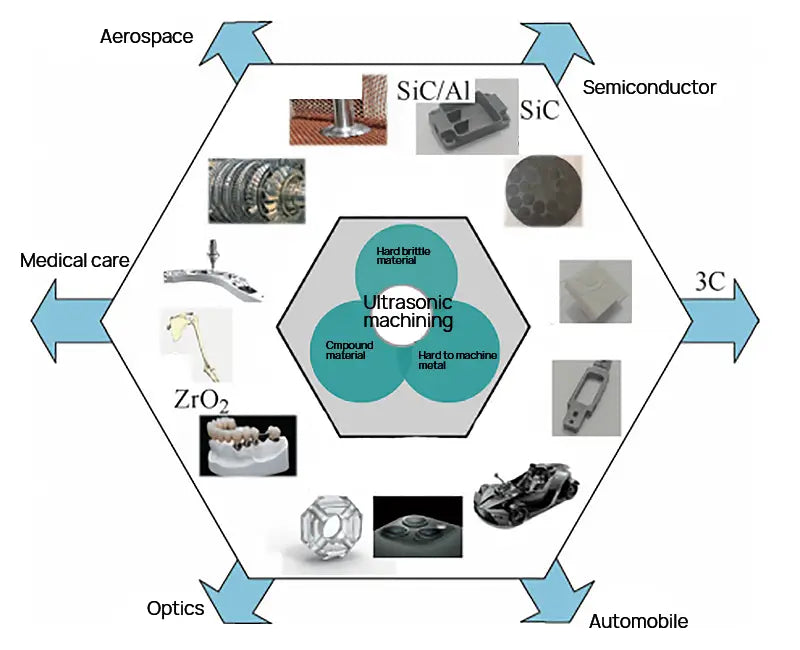

Ultrasonic machining is a specialized technology used to machine difficult-to-process materials, such as hard and brittle materials, composite materials, and challenging metallic materials. It has significant potential for use across multiple industries, including aerospace, automotive, semiconductors, 3C, and medical.

The technology works by using ultrasonic vibration energy to precisely remove material from difficult-to-machine materials.

In recent years, ultrasonic machining technology has seen significant development due to the collaboration of national and international universities, research institutes and companies. There have been numerous successful applications of ultrasonic machining in the precision machining of various challenging materials.

As a representative of advanced manufacturing technology, ultrasonic machining will play a crucial role in improving the overall manufacturing level.

1. Preamble

In recent years, advanced engineering materials such as titanium alloys, superalloys, engineering ceramics, ceramic matrix composites and honeycomb composites have emerged in various manufacturing fields, including aerospace, automotive, semiconductor, 3C and medical. These materials have excellent performance but poor machinability and are considered difficult to machine materials.

Traditional mechanical manufacturing technology faces challenges when it comes to precision machining of these materials. To overcome these limitations, ultrasonic machining (UM) has gained attention and become widely used.

Ultrasonic machining is a process technology that uses ultrasonic vibration energy to accurately remove material from difficult-to-machine materials. This technology concentrates the energy of ultrasonic vibration in the tool's working area through a series of transmissions and structural transformations, resulting in an impact removal effect on the material to be cut and improving its machinability.

Ultrasonic machining technology has several advantages in the machining process, such as reducing cutting force and heat, minimizing tool wear and edge collapse burrs, optimizing chip morphology, improving surface quality, reducing damage subsurfaces and increased machining efficiency.

It is important to note that ultrasonic machining technology is based on power ultrasonic technology and is a physical removal process that does not change the properties of the material.

Due to growing market demand, commercial systems standardized in ultrasonic machining technology have become a focus of the current market. Relevant ultrasonic machining technologies have been applied to the precision machining of various difficult-to-machine materials such as optical glass, sapphire, ceramics, alumina ceramics, titanium alloys, superalloys, carbon fiber composites and carbon fiber-based silicon carbide composites. aluminum.

Many scientific research institutions and manufacturing companies are now applying ultrasonic machining technology in industry.

Fig. 1 Application fields and typical cases of ultrasonic machining

2. Development status of ultrasonic machining technology

“A sharp tool is necessary to do a good job.” Ultrasonic machining technology is a sharp tool for precision machining of difficult materials. In most cutting fields, ultrasonic machining is called “ultrasonic-assisted precision machining”, which means using ultrasonic vibration to improve traditional cutting technology and achieve a special material removal effect. However, in some cases, ultrasonic vibration becomes the main or even the only cutting power, and this type of ultrasonic machining can be called direct ultrasonic machining.

For example, the ultrasonic scalpel used in the medical field for cutting bones and the ultrasonic knife used in processing aviation honeycomb parts are examples of direct ultrasonic machining.

In the 1920s, scientists from the United States, Japan, Germany and the Soviet Union began basic vibratory machining research, focusing on improving cutting conditions for breaking material chips. This initial research was mainly in the area of ultrasonic turning and relied on low-frequency vibration machining, which had a frequency quite different from the current ultrasonic frequency above 15KHz.

In the early 2000s, due to the increasing number of difficult-to-process materials, universities and research institutes in China began research into ultrasonic machining technology. This research covers equipment design, control technology, ultrasonic machining systems and ultrasonic technology.

Ultrasonic machining technology went through an early stage from its inception until about 2000, and then a rapid development stage for more than 20 years. Over the past five years, the rapid and large-scale application of difficult-to-process materials has accelerated the commercial development of ultrasonic machining technology.

At present, ultrasonic machining equipment, ultrasonic vibration control and technology are gradually maturing both domestically and internationally, which also deepens people's understanding of the basic requirements, working mechanism, process characteristics and application fields of ultrasonic machining technology .

In addition, more and more universities and research institutes are conducting research on ultrasonic machining technology, and the application fields of ultrasonic machining are expanding.

3. Basic principle of ultrasonic machining technology

Currently, the understanding of ultrasonic machining technology is still evolving and there is no unified standard or specification both nationally and internationally.

The conventional ultrasonic machining system typically consists of an ultrasonic drive controller, ultrasonic transmitter, transducer, horn, clamping frame and cutter, as shown in Figure 2.

This article will cover the characteristics of ultrasonic machining technology through the classification of ultrasonic machining system, the typical structure of ultrasonic machining system, ultrasonic drive control technology and ultrasonic process technology.

Fig. 2 main components of the ultrasonic machining system

3.1 Classification of ultrasonic machining system

Ultrasonic machining can be classified based on the form of ultrasonic vibration into one-dimensional, two-dimensional and three-dimensional ultrasonic machining. Vibration forms include longitudinal (axial) ultrasonic vibration machining, torsional ultrasonic vibration machining, elliptical ultrasonic vibration machining, and compound ultrasonic vibration machining, with the latter involving a combination of different ultrasonic vibration forms.

According to the vibration starting materials, ultrasonic machining can be divided into electrostrictive ultrasonic machining and magnetostrictive ultrasonic machining. The first is based on piezoelectric ceramic vibrating starting principle, driven by applying voltage, with simple structure and mature technology, but limited vibration power, making it more suitable for light-load cutting conditions. The latter is based on the magnetic field conduction principle of giant magnetostrictive or magnetostrictive materials, with large vibration power capacity but a complex structure, making it more suitable for heavy cutting conditions.

In terms of power transmission mode, ultrasonic machining can be divided into wired power transmission ultrasonic machining and wireless power transmission ultrasonic machining. The former is often used in low-speed machining without rotary motion or using brushes, while the latter is generally used in rotary ultrasonic machining. Wireless power transmission is realized through the loosely coupled contactless method and can be divided into fully coupled ultrasonic machining and partially coupled ultrasonic machining. The latter is the most adaptable for automatic tool changing on machine tools today.

According to the process types, ultrasonic machining can be divided into ultrasonic milling, ultrasonic turning, ultrasonic drilling, ultrasonic grinding, ultrasonic polishing, ultrasonic cutting and ultrasonic hardening (strengthening). Each process has specific requirements regarding the size of the ultrasonic energy and the form of vibration.

In terms of machining precision, ultrasonic machining can be divided into precision ultrasonic machining and ultrasonic ultrasonic machining. The difference between the two is in the amount of material removal per cutting unit, with removal accuracy requirements of less than 1μm considered as ultra-precision ultrasonic machining. Elliptical ultrasonic machining is typically used for micro nano cutting.

Finally, ultrasonic machining can be divided into traditional ultrasonic machining and high-speed ultrasonic machining. The latter refers to ultrasonic machining with a linear speed of up to 400m/min.

3.2 Typical structure of ultrasonic machining machine

A typical ultrasonic machining machine tool is illustrated in Figure 3. It consists of an ultrasonic drive controller, a wireless power transmission module, an ultrasonic tool holder, a tool, a numerical control system, and a machine tool.

The ultrasonic drive controller comprises an ultrasonic generator, an ultrasonic power amplifier, an ultrasonic feedback detection and an ultrasonic controller. The ultrasonic transmitter and ultrasonic receiver constitute the wireless power transmission module.

The ultrasonic tool holder is the main functional component of the ultrasonic machining system, usually composed of the ultrasonic receiver, transducer and horn. The ultrasonic machining system and the CNC machine tool system must have a certain level of communication control to ensure the smooth running of the entire machining process.

Fig. 3 structure of a typical ultrasonic machining machine

3.3 Ultrasonic machining system driving control technology

The drive control technology of the ultrasonic machining system is critical to realizing the benefits of ultrasonic machining technology, and the performance of the controller is the key to evaluating the performance of ultrasonic machining.

In the machining process, the ultrasonic drive controller must control various parameters, including the most important ultrasonic frequency and power, as well as the frequency resolution, response speed and amplitude fluctuation of the ultrasonic machining system. These parameters are crucial in determining the effectiveness of material processing.

The process of cutting tools in and out of materials is a typical time-varying, strong-load process, which means that the cutting force changes significantly in a short period. In this process, the impedance characteristics of the ultrasonic machining system and the electrical characteristics of the control system will undergo significant changes, making it essential to maintain amplitude stability.

The frequency resolution and accuracy of the ultrasonic controller and the system response speed are critical parameters in this process. Figure 4 shows the change in system characteristics during a typical ultrasonic cutting process. As shown in the figure, when the tool begins to enter the machining state, the cutting force increases instantly. To ensure the stability of the ultrasonic amplitude during the cutting process, the system adjusts the internal control parameters (such as frequency and power) to maintain a stable vibration amplitude during the machining process. A similar process occurs when the tool cuts the material.

Fig. 4 Changing state characteristics of ultrasonic machining system

During ultrasonic machining, changes in load and temperature result in significant changes in system characteristics during the machining process. Fast frequency tracking is crucial for effective ultrasonic machining, and common methods include the maximum current method, the phase-locked loop method, and the maximum power method.

Adaptive ultrasonic power control technology is also an important aspect of ultrasonic machining, aiming to solve the problem of the tool being unable to complete effective cutting due to the suppressed amplitude after loading. These tests require the ultrasonic machining system to have real-time feedback detection of the state of the ultrasonic actuator. Therefore, ultrasonic vibration feedback detection is a crucial part of achieving stable ultrasonic machining.

Currently, advanced algorithms are being applied in this process, including PID, fuzzy algorithms and artificial neural networks. The core of these algorithms is to identify the state during the machining process, ensuring the robustness of the machining process.

4. Process characteristics and application of ultrasonic machining technology

For materials with varying properties, the material removal mechanism and effect of ultrasonic machining can vary greatly.

Hard-working materials can be classified into three categories: hard and brittle materials, composite materials and difficult-to-machine metal materials.

Hard and brittle materials such as glass, ceramics, tungsten steel and ceramic-based materials are typically processed with diamond tools. During processing, the hardness of the material must be considered and efforts must be made to reduce the cutting force and improve the processing quality through ultrasonic processing.

Composite materials, such as carbon fiber reinforced composites, aramid fiber composites, and honeycomb composites with low stiffness, require selection of appropriate shapes and ultrasonic vibration amplitudes based on material properties to reduce cutting force and delay wear of the tool.

Difficult-to-machine metal materials, including titanium alloys, high-temperature alloys, high-strength steels and other metals with high toughness, require solving the tool adhesion problem, reducing the cutting temperature and delaying tool wear. Ultrasonic vibration requirements for these materials differ greatly from those for hard and brittle materials, and torsional vibration or longitudinal twisting is often used, with relatively high amplitude requirements.

For metallic materials, the ideal machining scenario involves complete intermittent cutting of the material, efficient cooling and lubrication in the cutting area.

The following summarizes the main process characteristics of different materials during ultrasonic machining.

(1) Hard and brittle materials:

Materials such as glass, ceramics (alumina, zirconia, silicon carbide and silicon nitride), ceramic-based materials, glass ceramics and other materials with high hardness and brittleness are considered hard and brittle materials.

The main challenges in processing these materials include significant surface damage, rapid tool wear and low processing efficiency.

Ultrasonic machining can help improve the cutting state, leading to longer tool life, better surface quality and greater machining efficiency.

Figure 5 shows a comparison of the average cutting force between ultrasonic machining and conventional machining of semiconductor silicon carbide (SIC).

Fig. 5 Comparison of average cutting force between ultrasonic machining and ordinary machining of silicon carbide

(2) Composite Materials:

Carbon fiber reinforced and aramid fiber reinforced composites are prone to surface damage, tearing, delamination, low processing efficiency and rapid tool wear during processing.

However, ultrasonic machining can significantly increase tool cutting capacity, reduce burr and extend tool life.

Figure 6 shows the result of ultrasonic machining on aviation honeycomb material.

a) Machining with disc cutter

b) machining with straight edge milling cutter

Fig. 6 Ultrasonic machining of aviation honeycomb materials

(3) Metal materials that are difficult to machine:

Metal materials with a certain level of toughness, such as titanium alloys, high-temperature alloys and high-strength steels, are prone to problems such as tool adhesion and rapid tool wear due to high processing temperatures.

Ultrasonic machining can reduce cutting force, lower cutting temperature, improve chip shape, reduce tool adhesion and extend tool life.

Figure 7 shows a comparison of tool wear between ultrasonic machining and conventional machining of titanium alloys.

a) Comparison of cutting tools under different removal amounts

b) Comparison and improvement rate of tool wear under different removal amounts

Fig. 7 Comparison of tool wear between ultrasonic machining and ordinary machining of titanium alloy

5. Future development trend of ultrasonic machining technology

At present, ultrasonic machining technology is advancing rapidly.

The availability of several new materials provides a solid foundation for the application of ultrasonic machining.

As a result, ultrasonic machining has become a powerful tool for precision machining of these materials.

In the future, ultrasonic machining technology will continue to develop rapidly as the industry advances.

At the same time, the following research areas are likely to become the focus of future scientific research and engineering applications.

5.1 Advanced ultrasonic composite energy field technology

In the future, multidimensional ultrasonic machining technology will be increasingly used, and the development of control technology and corresponding process technology will be a key area of research.

Furthermore, the integration of ultrasonic, laser, plasma and other processes into a composite technology is a crucial direction for the future development of ultrasonic machining.

The use of multiple energy fields in the processing of difficult-to-machine materials will bring unique benefits, facilitating processing.

5.2 Fast, accurate and stable control algorithm and control system

The actual cutting process is different from static or quasi-static processes.

Variations in materials, tools and cutting parameters can have a significant impact on cutting force, cutting temperature and system impedance characteristics during machining. The strong time-varying load can also cause instability in the ultrasonic machining system.

To achieve efficient and accurate machining, it is crucial to ensure the stability of the ultrasonic machining system through fast, accurate and stable control algorithms.

In the future, more advanced control algorithms will be incorporated into the ultrasonic machining process.

5.3 High speed and efficiency of ultrasonic machining

In traditional precision machining, it can be challenging to achieve high machining quality and efficiency, especially when machining complex structural parts in the aerospace industry.

To ensure machining quality, machining efficiency is often compromised.

However, when ultrasonic machining is applied to process difficult-to-machine materials in this field, such as titanium alloys, superalloys and carbon fiber composite materials, its unique intermittent cutting mode allows periodic opening of the cutting area during the cutting process. cutting, improving cooling and lubrication, reducing cutting force and temperature, and increasing cutting speed. As a result, high-quality and efficient precision machining can be achieved.

5.4 Formulation of ultrasonic machining standardization system

The capability of the ultrasonic machining process is a clear demonstration of its advantages.

A thorough understanding of process capability can help fully utilize the capabilities of ultrasonic machining.

As technical research advances, more specialized tools, accessories and corresponding process parameters for ultrasonic machining will be available, allowing greater utilization of its capabilities.

However, currently, there is no unified standard for ultrasonic machining technology.

The saying goes: “To know righteousness, you must follow the standard; To get to know the surroundings you need to follow the rules.

Accelerating the development of industrial and national standards will help remove technical barriers and promote the widespread adoption and development of ultrasonic machining technology.

6. Conclusion

It is important to note that ultrasonic machining technology is not a one-size-fits-all solution for difficult-to-machine materials.

Different types of ultrasonic machining have their own strengths and limitations, and it is crucial to be familiar with the characteristics of the technology and understand the process requirements for an ideal application.

Ultrasonic machining technology is a cutting-edge manufacturing technology with enormous growth potential and serves as a crucial technical support for manufacturing power.

As the use of difficult-to-machine materials increases, ultrasonic machining technology will be rapidly adopted and developed.

In the future, ultrasonic machining technology will provide solutions to precision machining problems for an even wider range of difficult-to-machine materials.