Pumps simplify the transport of water and other fluids, making them very useful in all types of buildings – residential, commercial and industrial. For example, fire pumps provide pressurized water supply to firefighters and automatic sprinklers, water booster pumps provide drinking water to the upper floors of tall buildings, and hydronic pumps are used in HVAC systems that use water to provide heating and room cooling.

There are many pump designs, but most types can be classified into centrifugal and positive displacement pumps. This article will provide an overview of each pump type, comparing their performance characteristics.

Centrifugal pumps

A centrifugal pump uses an impeller, which has curved blades that accelerate the fluid outward during rotation. The impellers are normally driven by an electric motor or combustion engine and their movement produces suction at the pump inlet, drawing water inside.

Based on the type of water flow they produce, centrifugal pumps can be classified into three subtypes. The flow pattern is determined by the impeller shape and pump construction.

|

SUB-TYPE |

DESCRIPTION |

PERFORMANCE |

|

Axial flow pump |

Also known as propeller pump, it produces water flow along the direction of the impeller shaft. |

High flow |

|

Radial Flow Pump |

This type of pump produces flow in a direction perpendicular to the axis (90° angle). |

Low flow |

|

Mixed Flow Pump |

This type of pump combines radial and axial flow, producing a conical flow pattern around the shaft. |

Average flow rate |

Centrifugal pumps are the most common type as they are suitable for handling water and relatively easy to manufacture. These pumps also tend to have a lower price, as mass production has reduced their production cost.

Make sure your building's pumping systems are professionally designed.

Positive Displacement Pumps

Positive displacement pumps move a fixed amount of fluid at regular intervals. They are built with internal cavities that fill on the suction side, to be discharged with greater pressure at the exit. Based on how the fluid is displaced, positive displacement pumps can be reciprocating or rotary.

|

SUB-TYPE |

DESCRIPTION |

EXAMPLES |

|

Alternative Pump |

The flow is established within a cavity that expands and contracts, like a piston. Water enters the cavity during expansion and is forced out during contraction, while the direction of flow is controlled using check valves. |

Bladder |

|

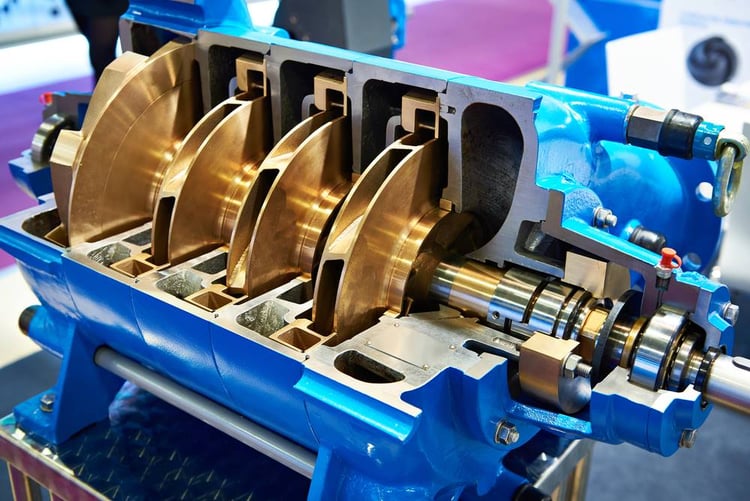

Rotary Pump |

This type of pump uses a rotor that retains water in the cavities, releasing it at the exit. These cavities can be spaces between gear teeth or screw threads, among other configurations. Some designs use more than one axis, but the principle is the same: the shape of the rotor is designed to capture “pockets” of water and move them in the intended direction. |

Gear |

How do centrifugal and positive displacement pumps compare?

Both types of pumps move fluids in a specific direction, but accelerating a fluid continuously is not the same as displacing it by fixed amounts. As a result, there are important performance differences between the two types of pumps.

When pumps are driven by an electric motor, a variable frequency drive (VFD) can provide major energy savings by reducing engine RPM when full pump speed is not required. However, you should check compatibility: some pumps are incompatible with VFDs, while others allow speed control above a minimum RPM value.

VFDs and other pump controls can be combined with NEMA Premium Efficiency motors to achieve the lowest possible operating costs.

Conclusion

The pumps have multiple applications and are widely used in residential, commercial and industrial buildings. As a result, a wide variety of pump designs have been developed. However, variety can also cause confusion, and using the wrong pump for an application can cause wasted energy or even equipment damage.

To ensure that all of your building systems utilize the correct types of pumps, the best recommendation is to work with qualified MEP engineers. They can also help you integrate VFDs and other control features during the design phase, saving you thousands of dollars in energy bills over time.