Joint tapes are used to prevent water from penetrating construction and movement joints. Construction joints in liquid-tight structures must be provided with adhesive tape.

The selection of waterstops should be based on the type of construction and their applicability. Not all types of joint tapes can be used on all concrete structures.

No water stops are used within the structures. It must be connected to other waterproofing systems. The following occasions can be identified as places where we use water stops.

Furthermore, different types of joint tapes are not used in the same construction due to their compatibility. For example, it is very difficult to expose the steel joint with PVC joint tapes.

Water barriers are typically used in the following constructions:

- Basement walls

- Basement slabs, slab foundations when used as a basement floor.

- Subway and tunnel

- channels

- Overflow walls and keel arches

- Other fluid retention structures

Normally the water stop is on Construction joints Contraction joints, movement joints and expansion joints. If there are waterproofing requirements, the only way to avoid them is to stop irrigation.

Let's discuss the different types of water stops.

- PVC Joint Tapes

- Rubber joint tapes

- Metal joint tapes

- Bentonite Joint Barriers

- Hydrophilic joint tapes

PVC water stopper

PVC joint tapes are widely used construction elements. They are very easy to use and handle at the construction site and the cost is also comparatively cheap.

PVC waterstop is used for movement joints and expansion joints due to its ability to accommodate the movements of structures.

PVC joint tapes are becoming more popular due to the following advantages.

- High flexibility.

- High elasticity and tensile strength.

- Low water absorption.

- Corrosion resistant.

- It is not affected by low temperatures and immersion in water.

- Withstands high hydrostatic pressure and shock.

- Weather resistant and excellent durability.

Tests must be carried out to ensure that the water stop behavior is acceptable for the project. In general, testing can be performed at the time of supplier selection. Testing standards can vary greatly from country to country.

| Physical properties | Test Methods |

| Water absorption | ASTM D-570 |

| Tear resistance | ASTM D-624 |

| specific weight | ASTM D-792 |

| Shore hardness A15 | ASTM D-2240 |

| tensile strength | ASTM D-638 Type IV |

| Maximum elongation | ASTM D-638 Type IV |

| 100% module | ASTM D-638 Type IV |

| Low Temperature Brittleness (Tb) °F (°C) | ASTM D-746 |

| Bending rigidity | ASTM D-747 |

| Ozone resistance | ASTM D-1149 |

| Change in Shore A hardness | ASTM D-2240 |

Let's discuss the layout of the water stops at each location.

Surface water barriers in front

Surface water barriers are used to prevent the movement of water through construction joints, shrinkage joints, movement joints and expansion joints.

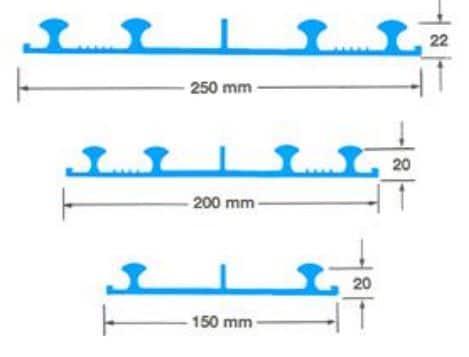

The water barriers used in construction joints are not the same as those used in expansion and movement joints. The following figure shows water barriers used for shrinkage and construction joints.

The sizing of the water barrier must be selected depending on the intended use and other technical properties.

If expansion or movement of the structures is necessary, this must be allowed by the joint tapes. The segment in the middle of the joint tapes is modified so that movements are possible.

The following illustration shows the typical type of joint tape for use in expansion and expansion joints .

Dimensions shown in the image above may vary depending on the supplier and product specification. Furthermore, dimensions can be selected according to the technical requirements of the project.

If there is also an external seal below the foundation, this can be continued normally and must not be interrupted at these joint barriers.

The following figure shows the method of placing water barriers in concrete.

Internal joint barriers

A joint tape is placed in the middle of the construction, retraction and movement joints. Joint tapes with central cord are intended for expansion and movement joints.

Normal joint tape can be provided at construction and expansion joints. The following image shows the typical type of masking tape used in the center.

The following figure shows the types of water bars available on the market.

PVC Water Stop Welding

If the length is not sufficient or the joints need to be provided in different directions, PVC joint barriers can be welded.

Welding is done by heating the water seals together and holding them in place for some time until the connection is made.

As indicated in the figure above, waterstops can be continued in any direction depending on construction requirements. If there are tightness requirements and joint barriers are provided, these must be installed at all construction joints.

Rubber joint tapes

Rubber gasket tapes are available in similar designs to PVC gasket tapes. Rubber joint tapes are made from natural rubber or synthetic rubber.

Rubber joint tapes are used in the following construction areas:

- Ideal for joints with high movement.

- Water inclusions.

- Water excluded.

- Tunnels and engineering structures.

- Water and waste treatment.

- Dams, reservoirs, diversion tunnels and spillways.

- Chemical areas.

- Irrigation canals, dikes and culverts.

- Sewage treatment station

- Pool

- reservoirs

- water tank

- Underground areas

- underground parking

- retaining walls

- Hanging dishes

- wells

- Roof Panels

The following features and benefits can be seen in rubber water barriers.

- Excellent elasticity and flexibility.

- High elasticity.

- Excellent adaptation to large movements.

- Can withstand a high water column.

- Adjust for settlement and seismic movements.

- Abrasion and tear resistant.

- Resistant to corrosion and chemicals.

- Resistant to weather and aging.

- Excellent sealing effect.

A similar construction method can be used to install rubber gaskets as for PVC installation. Additionally, model intersections are also available for construction.

Metal joint tapes

The main metal water barriers used are mild steel, galvanized steel and copper. Copper water barriers are not widely used. However, they are used in special cases, such as hydraulic structures with very high heads and anticorrosive properties.

- Mild Steel Water Stop : These types of joint barriers are often used in construction. The construction cost is also less compared to other types. The main disadvantage of using carbon steel is corrosion. Water penetration to the joint barrier through the construction joint increases corrosion of the joint barrier. Joint barriers made of medium steel cannot be used in expansion joints and construction joints due to the poor expansion properties of steel. PVC and rubber joint barriers can withstand the movement of structures and stretch very high. Furthermore, the sealing of the joint can be continued by welding.

- Galvanized Steel Water Stop : Using galvanized steel for construction joints as joint tape is a permanent solution. Because carbon steel can corrode when exposed to the environment, galvanizing provides additional protection. Galvanized steel joint tape cannot be used for expansion and movement joints.

- Stainless Steel Water Stopper : Stainless steel can also be used as a water barrier. However, due to the cost of materials, it can only be used on special occasions. Stainless steel water stops are often used in corrosive environments.

- Copper Water Stopper : Copper water barriers are not commonly used in construction. They are used in special structures such as dams, overflow pipes, etc. due to corrosion problems. If we install a steel water barrier in these locations, it may corrode over time. Furthermore, these structures are built to last over 100 years and the water barrier cannot be repaired if damaged for any reason as we cannot empty the reservoirs. PVC water barriers and copper water barriers are widely used in hydraulic structures.

Bentonite Water Stop

Bentonite joint tapes are hydrophilic joint tapes based on bentonite. These joint tapes are attached like strips to construction joints. These joint tapes cannot be installed on all types of joints. In particular, they cannot be used in expansion and movement joints.

Bentonite joint tapes are generally installed on construction joints. They are placed in the groove created in the middle of the construction joint, as shown in the following figure.

Furthermore, there are different types of joint barriers with different properties that can be used in different locations.

Advantages and special features

- Activated by moisture.

- Robust and durable in comparison

- Cost effectiveness.

- High water absorption with excellent compression sealing.

- High expansion control capacity to maintain integrity.

- Controlled internal pressure in the surrounding concrete to prevent spalling and cracking.

- Withstands high water pressure.

- Capable of self-healing.

- Easy to connect/overlay

- Non toxic

These types of water barriers are applicable to the following structures.

- Pipe penetrations in concrete

- Joints with limited mobility

- Construction joints

- Water retention and reservoirs

- Water and wastewater treatment

- Manholes and elevator shafts, manure pits

- Tunnels, culverts, dams, water tanks and canals

- Pool

- retaining walls

- Precast concrete construction

- Foundations and basements

- dishes

Hydrophilic Water Stop

Hydrophilic joint tapes are swellable joint tapes that react to water. The material becomes active when moisture hits it. When it comes into contact with water, it increases in volume. However, the expansion does not harm the structure.

Connects construction joints and prevents water from penetrating the joint.

They are installed in joints where relative movements do not occur. Expansion joints and movement joints are not waterproof with these joint tapes.

Furthermore, they are used to maintain waterproofing when pipes are embedded in concrete walls. A waterstop is installed around the pipes.

The following figure shows the arrangement of the waterstops and the location where they should be installed.

Construction details on water barriers

The following construction details are used in construction. These details refer to hydraulic structures.

Detail 01 – Movement articulation

Detail 02 – Expansion joint

Detail 03 – Expansion joint

Detail 04 – Expansion joint

Detail 05 – Movement articulation

Detail 6 – Construction joint