The shear wedge is a part of the structural element that mainly serves to make the structure stable against lateral loads. Depending on the type of construction and the type of load, the application of shear varies.

Most often, shear wedges are constructed between two structural elements. However, in structures such as retaining walls, they are connected to the main structure, but stability is guaranteed by being supported on the ground.

What is the purpose of a shear key?

The main purpose of the shear wedge is to maintain the integrity of the structure. In general, although we allow the transfer of shear forces, we do not transfer the bending moment through the shear wedge.

That is, the shear forces due to lateral or applied loads are transmitted through the shear key in the connection between the structures.

Classification of shear springs

The classification is based on the type of structure, design, magnitude of applied loads, etc.

Although the shape of the key is not yet fully designed, typical values provided in detailing manuals can be used to finalize the dimensions.

However, if the applied loads are critical, a special design must be carried out.

Based on the type of construction, the location and classification of shear springs must take into account the applied loads, construction sequence, etc.

The following reason can be discussed in relation to shear springs.

- Retaining walls (external)

- Basement walls, retaining walls (internal)

- Shrinkage joints in gravity and reinforced concrete structures

- dishes

- Pub

- Slab foundations

- Steel Column Foot Connection

- Connection of prefabricated parts

- Masonry

Let's discuss each type in detail.

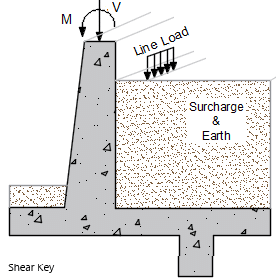

Shear teeth in retaining walls (external)

Lateral loads acting on the retaining wall are absorbed by the friction of the base and any projections of the base.

To some extent, concrete can withstand subsequent loads due to friction between the concrete and the rock.

The article on Retaining wall stability For more information on stability analysis can be found here.

Depending on the applied loads (active pressure and passive pressure), the shear key must be designed for bending and shearing.

Basement wall and retaining walls

We generally offer Construction joints just above the base. However, we do not supply shear springs for thinner walls.

As the wall thickness increases, the lateral loads increase and we also provide the shear connections to absorb the shear forces.

A horizontal construction joint may be a good option because it has low shear strength. Therefore, we need to provide a wedge to support the lateral loads.

If the wall thickness exceeds 500 mm, it can generally be assumed that there is a shear element at the construction joint. However, there is no specific requirement for the presence of a shear gear element.

Joint stopper can be provided depending on the wall waterproofing requirements. The construction joint must be rough enough to ensure sufficient adhesion.

Shrinkage joints in gravity and reinforced concrete structures

Expansion joints exist in many types of structures.

In this article we discuss shear springs in shrinkage joints of large structures.

For more information about construction joints, see the article Types of Concrete Joints .

There are several shear wedges fixed to the wall.

As shown in the illustration above, there are additional wedges in the contraction joint that provide lateral stability through the connection.

The force applied to each key would be less and failure would occur due to the shear forces of the keys.

Plate Shear Wedges

Shear anchors are provided for the slab based on the applied loads and the slab span. If there is no larger gap, we can do without the shear pin in the slab.

With even thinner plates it is very difficult to form a shear spring. Therefore, for panels with a thickness of about 150 mm or less, most often no spring is provided.

Furthermore, pockets shaped like shear wedges are introduced into the plate to form shear wedges. They can be placed at a distance of 600 mm. This distance is based on the engineer's judgment based on the slab span and applied loads.

Shear teeth in beams

Due to limited resources, time required to complete a mold, etc., it is not possible to produce a floor slab in one go.

Therefore, two or more concrete pours are necessary to complete the concreting of the slabs.

The construction joint is in the slab and beams. Shear springs shall be provided in each beam and slab.

Beam shear wedges are placed in a similar manner to slabs.

However, shear dowels are also commonly used in beam construction joints.

Typical key depth and dimensions can be shown in the figure above. However, these values can be adjusted depending on other requirements, if any.

For a better connection of the concrete in two castings, the shear wedge must be sufficiently rough.

Shear Springs in Slab/Mat Foundations

Due to the volume to be poured and to minimize thermal effects, shear wedges are generally present in the slab foundations.

There are typical dimensions for wedges designed to absorb shear forces in foundations. Generally, we do not design shear wedges because they are very rigid and can withstand the applied loads.

The figure above shows the type of shear gear that can be used in slab foundations. Depending on the type of construction, Joint stopper available.

Joint barriers can be placed at the bottom of the foundation or in the middle of the foundation as shown in the image above. Joint barriers are generally placed when there are movement joints present.

Steel Column Foot Connection

Steel frames are subject to lateral loads due to wind action or depending on the type of loads acting on the structure.

Generally, changes are made to the foundation of the column that serves as shear reinforcement.

The dimensions of the inlay must be based on the applied loads and correspond to the connection details.

Shear expansion springs in precast connections

To ensure uniform load transfer, shear teeth are incorporated into the finished parts.

In general, the shear wedge is mostly made of concrete and, if done correctly, will be filled with mortar.

Deformation due to shear force in masonry

Shear wedges are installed in a masonry wall to support external and internal lateral loads.

The connection to the remaining walls is made through projections on the wall.

There may be joints in both vertical and horizontal directions.