Keeping your employees safe is critical, especially if you want to be successful, now and in the future. Although there are so many different types of hazards, the ones considered most deadly are electrical hazards. Any type of electrical hazard can cause an electrical shock, which is bad enough, but some of these shocks can also cause a person's heart to stop beating and they could end up dying from what seemed like such a small thing at the time. .

While you want to say that all of your employees are knowledgeable about electrical hazards and are safe on the job, you cannot completely guarantee this. It only takes a second for an electrical hazard to turn deadly, which is why it is critical to act quickly to remove all electrical hazards.

We know that you try to use state-of-the-art equipment and that you inspect it regularly. However, we also know that things happen, that inspections are left aside and that tools and equipment are sometimes used when they are past their limit.

It can be very dangerous to use any type of damaged tool or equipment, especially when the wires, cables or cords are cracked, cut or falling apart. You may be tempted to wrap these items with electrical tape to buy a little more time before replacing them, but this is dangerous for your employees.

We recommend replacing these items completely or hiring a professional repairman to fix them for you.

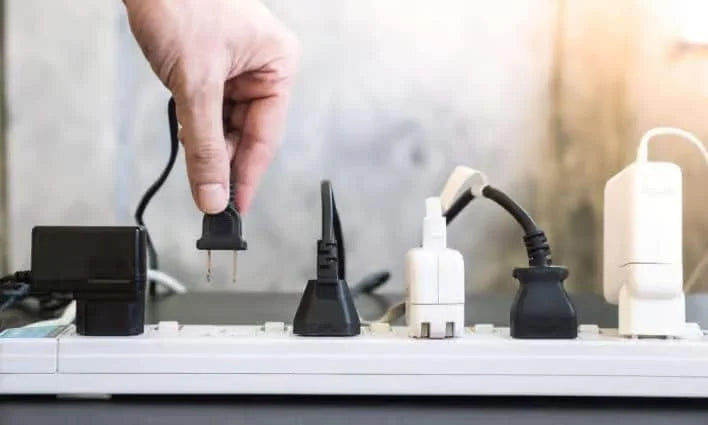

2. Overloaded Circuits

It's common to plug in extension cords, so you can plug more than two items into one outlet. However, all those extra cables can cause the circuit to overload, which could cause a fire.

You should also make sure all of your wiring is up to date, because even an underloaded circuit can become problematic if your wiring isn't up to code. Overheating can occur quickly and can easily start a fire inside the walls. The worst part about this is that the fire can burn and even smolder for hours before you realize what is happening.

3. Power lines

If you are working outdoors, you and your employees may encounter power lines. It is recommended that you all stay at least three meters away from these power lines and that you keep all your equipment away from them as well. Simply bumping into these power lines while working can cause electrocution or serious burns.

You may be tempted to store items under power lines, especially since there will be no workers in that area. However, this can be just as dangerous because if these power lines ignite, the items below can catch fire. This fire will then spread to the rest of the workplace.

4. Humid Conditions

Power is everywhere these days, but that doesn't mean you should mess with it in wet areas. If you need to plug something in but notice water nearby, move away immediately and alert someone that there is a dangerous situation. If you don't do this and choose to plug in the item anyway, you run the risk of being electrocuted as soon as the plug starts receiving power from the outlet.

You also shouldn't try to use any type of equipment once it's wet, as water and electricity don't mix and can cause electrocution as well.

5. Exposed electrical parts

There are some electrical parts that can become exposed over the years, but the most common include disconnected cable insulation, temporary lighting, and open distribution units. When these items are exposed, you are at greater risk of getting burned or shocked.

If you notice any exposed electrical parts, you should have them repaired immediately. Failure to do so would be unwise, so if you cannot repair them immediately, you should stop using these items until they can be repaired or replaced.

6. Damaged insulation

Insulation can also become damaged over time or simply stop working as it should. You should turn off all power in the area where you find damaged insulation so that an accident does not happen before it can be replaced.

You may be tempted to cover the damaged insulation with electrical tape, but that's the worst thing you can do. After all, this tape won't stop the flow of electricity and is just another thing that could catch fire.

7. Grounding is done incorrectly

It is always essential that you ground all electrical parts properly, as this is the only way to reduce the risk of unwanted voltage and prevent people from being electrocuted. The only thing we see most is the removal of the metal ground pin. Many people think that this pin is not necessary, but we can say that this is what keeps all the extra voltage going towards ground.

Now that you know what the most common electrical hazards are, you can easily walk around your workplace and start taking appropriate precautions. We also recommend holding a few safety meetings with your employees so you can share these electrical hazards with them and give them the knowledge they need to stay safe while doing their jobs. These meetings should also be repeated annually so that everyone can be reminded of the dangers of these seven electrical hazards.

You can even create a checklist that your employees can use every day when they arrive at work so they can spot new electrical hazards before they get to the point where they cause problems. If everyone checks certain items every day, you will have more success in keeping all of your employees safe and out of harm's way.

Don't waste time when it comes to electrical hazards and learn how to avoid them because you never know when a small electrical shock will cause permanent injury or even death.