Beam failure can occur through bending, torsion, and shear if design loads are exceeded in both failure modes. Depending on the type of load that can be applied to the beam and when the relevant factor load is reached, structural failure will occur.

Beam failure in bending

Sections are sized to x/d value 0.5 This is less than this Equilibrium x/d ratio 0.64 .

This allows for greater moment distribution during the loading phase and promotes ductile rupture.

At x/d = 0.5 the concrete elongation is 0.002, while at failure it is 0.0035. This allows for early warning, as the reinforcement gives way early and cracks appear as the deflection increases.

Providing more reinforcement than necessary without early action will lead to failure of the structure as the concrete reaches its breaking load sooner.

Concrete failure occurs suddenly and without warning.

However, if the reinforcement fails, stretching and deflection with cracking occurs.

If the amount of reinforcement also fails, less section. However, there are warnings of excessive deformation and cracking under load .

If the section was designed according to the guidelines specified in the code, warnings will be issued when an error occurs.

Warnings come in the form of cracks and excessive deflections.

Typically, flexion fractures are identified by cracks.

Depending on the crack pattern, one can conclude whether it is a flexural fracture, torsional fracture or shear fracture.

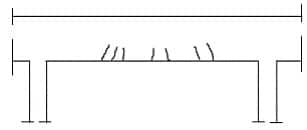

Figure 01 shows the cracks that were observed due to the increase in flexural stress above design values.

Flexural cracks before beam failure

Figure 01 Flexural cracks

Shear cracks before beam failure

If the design shear stress of the component is exceeded by the applied loads, shear cracks may be observed as the first warning as the load increases.

In these situations, immediate attention must be paid to avoid excessive loads and to study the effects of cracking on structural elements. Figure 02 shows that cracks occur as shear cracks in a beam.

Figure 02 Shear cracks in the beam

Torsional cracks before beam failure

Torsional cracking occurs in a section due to excess torsional moment in a section.

Insufficient torsional reinforcement and incorrect detailing methods can also cause cracking due to torsional moments.

In Figure 03 you can observe the formation of torsional cracks in the profile.

Figure 03 Torsional cracks in the beam

The torsional cracking patterns of beams are similar to the shear cracking pattern. However, torsional cracks propagate along the cross section, as shown in Figure 03, while shear cracks typically occur only on the sides of a cross section.

All types of cracks listed above give early warning because the sections are constructed according to the guidelines specified in the standards.

Necessary measures must be taken to determine the causes of the cracks. Furthermore, preventive measures and corrective work must be carried out to avoid new cracks.

Other types of beam errors

In addition to the flexural cracks discussed above, there are other types of cracks that can occur in components after construction. Mainly these are

- Corrosion cracks

- Shrinkage Cracks

Corrosion cracks

If reinforcement and concrete are exposed to extreme environmental conditions, this can cause cracks to form in the reinforcement.

Due to the initial cracking in the concrete section, the reinforcement can be exposed to the corrosive environment, creating a phase where corrosive materials can come into contact with the reinforcement.

Several tests are available to check the condition of concrete and determine whether the reinforcement is corroded.

The Carbonation Test and Chlorination Test are mainly carried out for this purpose.

The cracks run horizontally parallel to the reinforcement as shown in Figure 04. Furthermore, the cracking at the bottom of the section may also be due to inadequate coverage of the reinforcement.

Figure 04 Corrosion cracks

Shrinkage Cracks

There is no regular pattern for shrinkage cracks in a section. They occur in weak areas and depend on the evaporation of water from the concrete surface. Additionally, inadequate reinforcement also causes the concrete to crack as it dries.

Figure 05 Contraction cracks

Figure 05 Contraction cracks

Beam failure can occur in several ways, as explained above. In summary, this article discussed the causes of beam failure caused by different types of cracks.

There are several articles on beam design, including Floor Joist Construction that you could study to learn more about design aspects.