The type of column failure depends on the type of structural system and columns can fail in different ways, as discussed in this article.

The pillar is the main element that transfers vertical loads to the foundation. The failure of one support can lead to the failure of the entire structure. Therefore, failure of supports, like any other element, must be avoided.

Furthermore, pillar failure can lead to gradual collapse of the structure. Therefore, it is very important to identify the critical pillar and pay attention to it during planning and construction.

The following types of column failures have been identified.

- Pure compression error

- Combine stress errors

- Buckling failure

- Shear failure

- Failure due to lack of containment reinforcement

- Torsional failure

- Failures due to construction defects

- Failures due to design errors

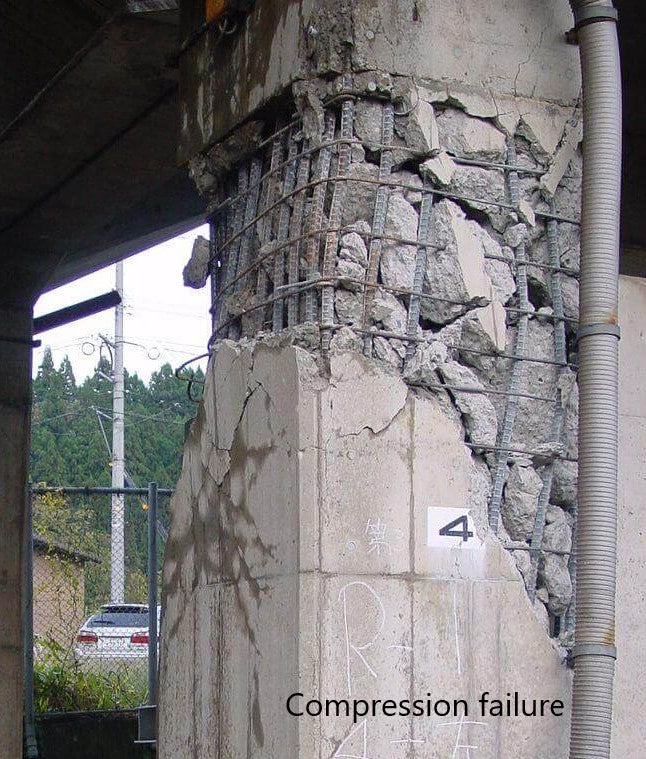

Pure compression errors

A column is an element that transfers the weight of a structure as axial stress to the foundation or supporting element.

Concrete is capable of withstanding compressive loads and predominates in load-bearing, while in other elements such as beams, compressive stress is absorbed only by a part of the cross-section.

Reinforcement is also provided for supports where the concrete cannot support the entire load or serves only as nominal reinforcement.

The column may fail during compression if the axial stress exceeds its capacity. These types of failures may be due to the following reasons.

- Reinforcement and concrete have a certain bearing capacity, which depends on the quantity and cross-sectional area. If the axial stress is greater than this load capacity, the column will fail under compression.

- Furthermore, reinforcement and concrete have their own loads that they can support. According to British standards, concrete can withstand a load of up to 0.0035, and steel begins to sag at a load of 0.002, and this may be greater than that of concrete. When the axial stress exceeds a certain value, resulting in concrete stress exceeding 0.0035, the concrete suddenly fails. Concrete breaks suddenly.

- If the section is sufficiently reinforced, it will warn against such support failures. The article was published as Structural cracks in concrete Additional information about cracks can also be consulted.

Combined stress failure

In addition to axial forces, concrete columns are subject to bending moments due to the eccentric moment created by unbalanced loads.

Bending stress and axial compressive stress are added to obtain the final stress in the section.

It is not a uniform tension. However, support rupture is based on the criteria explained above under pure compression rupture.

The most important thing the designer must consider when designing is possible load combinations and alternative load effects. If there are significant deviations in the spans, care must be taken during construction.

Buckling failure

Mainly, buckling failure can be identified as a design defect because we consider the effect of buckling in the design. If the designer is aware of this type of spine defect, he or she can take care of it.

The additional bending moment of the column and the slenderness of the column are taken into account in the design.

Furthermore, the effective height of the column is considered based on its buckling pattern.

Buckling failure. The name itself provides information about the nature of the failure. Therefore, we take this into account when designing. In addition to compression failure of columns, buckling failure is the other basic type of column failure.

We make connections with supports to avoid buckling. This is the basic idea of creating connections to supports that do not serve as shear reinforcement.

Shear failure

Lateral loads in a structure are supported by vertical members such as columns and shear walls.

When there are no shear walls, the supports support these lateral loads. If there are not adequate shear connections, these types of column failures can occur.

Lateral loads arise from wind, earthquakes, supporting structures, etc.

The pillars are provided with shear connections adapted to the shear forces acting on them. Furthermore, the size of the supports is increased in the shear direction to increase the shear capacity.

In general, column failure due to shear forces can be identified as a design defect. Designers should have provided sufficient joints or shear sections to accommodate the shear forces.

Failure due to lack of containment reinforcement

Vertical elements subject to cyclic loading are susceptible to failures of this type.

The cause of failure is mainly due to lack of connections in the area of higher shear forces.

Structural elements such as beams and columns experience greater stresses near the joints. Lack of connections in these areas leads to structural defects under cyclic loading.

The article appeared as Seismic Detailing of Beams and Columns provides clear guidance on how we should design the reinforcement in detail so that it can withstand cyclic loading.

Torsional failure

There is a probability that the supports are subject to torsional moments.

Typically, supports are designed for axial, bending, and shear forces. However, due to irregularities in the structure, torsional behavior of the support can be observed.

Compared to the beam, the supports are torsionally rigid because they have reinforcement around the section and the connections are made at smaller intervals.

However, if the torque exceeds the limits, torsional failure of the supports may occur.

The article appeared as 6 Causes of Beam Failure Discuss torsional failure of beams and their cracking patterns.

Failure due to design defects

Brackets may fail due to design errors. For example, improperly treated honeycomb in a column can cause failure when loads are applied. These types of spine failures can be avoided if great care is taken.

Voids within the column that have not been properly filled with soil reduce the pressure area of the column. This reduces its axial load capacity.

Furthermore, voids inside the column can cause cracks in the concrete. This exposes the reinforcement to the environment, leading to corrosion of the reinforcement.

Similar cases can lead to errors.

Failure due to design defects

Many errors may occur during construction, which can also be divided into different types of column failure. By employing qualified engineers on the project and closely monitoring construction work, these types of pillar failures can be minimized.

- Accidentally reducing the rod diameter

- Create a fake column instead

- Changes in concrete quality

- Lack of concrete strength due to the failure of the concrete supplier.