STEEL IN THE BRAZILIAN INDUSTRY

Overcoming 7 Common Quality Problems in Laser W...

Weld Drift/Deflection 1. Laser Possible Causes: 1) Unreasonable weld offset setting Connect to the basic HMI software, check the current offset, and determine how to change it...

Overcoming 7 Common Quality Problems in Laser W...

Weld Drift/Deflection 1. Laser Possible Causes: 1) Unreasonable weld offset setting Connect to the basic HMI software, check the current offset, and determine how to change it...

Shielding gas in laser welding: the most comple...

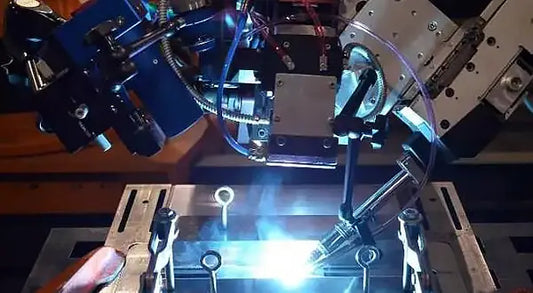

1. Laser Welding Gas In laser welding, a shielding gas is employed to improve welding results and prevent sediment build-up on laser tools. The shielding gas can...

Shielding gas in laser welding: the most comple...

1. Laser Welding Gas In laser welding, a shielding gas is employed to improve welding results and prevent sediment build-up on laser tools. The shielding gas can...

Laser Welding Sheet Metal: A Beginner’s Guide

Introduction Welding is a primary process in the manufacture of sheet metal, characterized by high labor intensity and adverse working conditions. As such, high proficiency is essential...

Laser Welding Sheet Metal: A Beginner’s Guide

Introduction Welding is a primary process in the manufacture of sheet metal, characterized by high labor intensity and adverse working conditions. As such, high proficiency is essential...

Fiber Laser Welding vs. Fiber Laser Welding CO2...

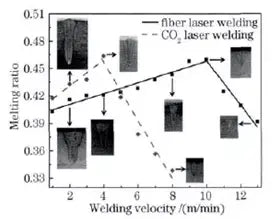

The main difference between fiber laser and CO2 laser welding lies in the absorption rate of laser energy. (1) Fiber laser has shorter wavelength, resulting in lower...

Fiber Laser Welding vs. Fiber Laser Welding CO2...

The main difference between fiber laser and CO2 laser welding lies in the absorption rate of laser energy. (1) Fiber laser has shorter wavelength, resulting in lower...

Choosing between continuous laser welding and p...

Pulsed welding of stainless steel sheet with Nd 3+ laser: YAG 1. Relevant principles Lasers can be classified in several ways. One classification method is based on length...

Choosing between continuous laser welding and p...

Pulsed welding of stainless steel sheet with Nd 3+ laser: YAG 1. Relevant principles Lasers can be classified in several ways. One classification method is based on length...

Exploring the impact of defocus in laser welding

1. Effect of Defocus on Laser Welding Defocus is the term used to describe the distance between the surface of a workpiece and the focal point. When the focal point...

Exploring the impact of defocus in laser welding

1. Effect of Defocus on Laser Welding Defocus is the term used to describe the distance between the surface of a workpiece and the focal point. When the focal point...