STEEL IN THE BRAZILIAN INDUSTRY

Understanding Internal Stress: Causes and Preve...

1. Internal stress generation In injection molded products, the stress state varies locally and the degree of product deformation will depend on the stress distribution. These tensions can...

Understanding Internal Stress: Causes and Preve...

1. Internal stress generation In injection molded products, the stress state varies locally and the degree of product deformation will depend on the stress distribution. These tensions can...

Fillet vs Chamfer in AutoCAD: Know the differen...

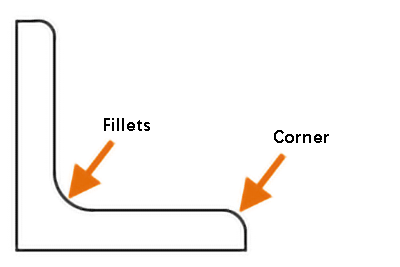

Definition Chamfering and filleting refer to the process of cutting the edges of a part on a given inclined or rounded surface. Purposes of chamfering and filleting The purposes of...

Fillet vs Chamfer in AutoCAD: Know the differen...

Definition Chamfering and filleting refer to the process of cutting the edges of a part on a given inclined or rounded surface. Purposes of chamfering and filleting The purposes of...

Heat treatment C curve: everything you need to ...

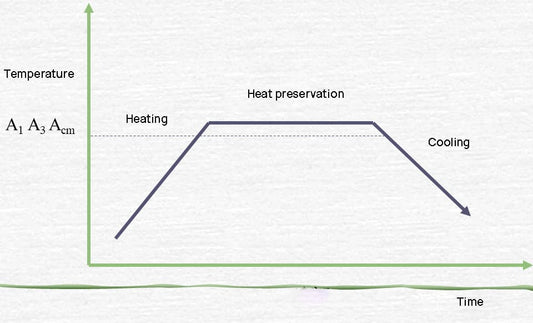

Principle of heat treatment CA curve C curve is a tool used to analyze the transformation of the microstructure of carbon steel during cooling after heating to form the...

Heat treatment C curve: everything you need to ...

Principle of heat treatment CA curve C curve is a tool used to analyze the transformation of the microstructure of carbon steel during cooling after heating to form the...

Pig Iron vs Wrought Iron: The Differences Expla...

Difference in Nature 1. Pig Iron Generally, pig iron refers to an iron alloy with carbon content ranging from 2% to 6.69%. It is also known as cast iron. In...

Pig Iron vs Wrought Iron: The Differences Expla...

Difference in Nature 1. Pig Iron Generally, pig iron refers to an iron alloy with carbon content ranging from 2% to 6.69%. It is also known as cast iron. In...

Surface Roughness: The Comprehensive Guide

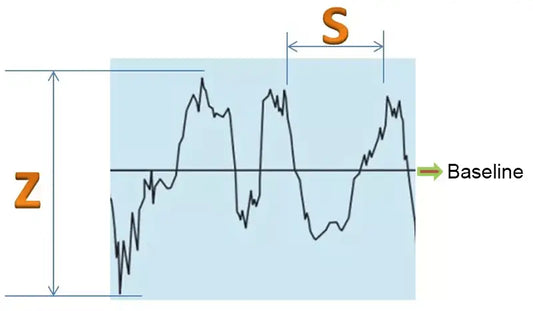

1. What is surface roughness? In technical communication, the term “surface finish” is commonly used. However, it should be noted that the “surface finish” is based on human perception...

Surface Roughness: The Comprehensive Guide

1. What is surface roughness? In technical communication, the term “surface finish” is commonly used. However, it should be noted that the “surface finish” is based on human perception...