STEEL IN THE BRAZILIAN INDUSTRY

Punching Machine: Working Principle and Mainten...

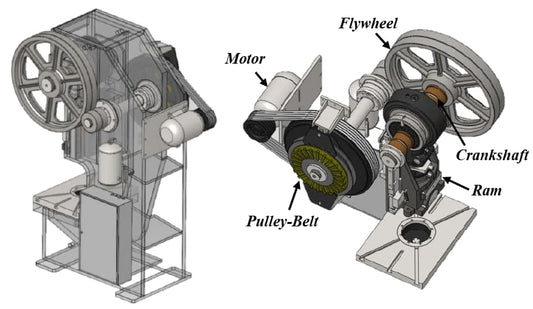

I. Working principle and maintenance of punching machines 1. Working principle of punching machines: Most of the punching machines we use today belong to this category, which is largely...

Punching Machine: Working Principle and Mainten...

I. Working principle and maintenance of punching machines 1. Working principle of punching machines: Most of the punching machines we use today belong to this category, which is largely...

Stamping Die Materials: A Comprehensive Overview

Materials used in the production of stamping dies include steel, carbide, steel-bonded carbide, zinc-based alloys, low-melting alloys, aluminum bronze, and other materials.

Stamping Die Materials: A Comprehensive Overview

Materials used in the production of stamping dies include steel, carbide, steel-bonded carbide, zinc-based alloys, low-melting alloys, aluminum bronze, and other materials.

Robotic Arm Printing: The Definitive Guide

The stamping robotic arm is a crucial component of smart manufacturing. Automatic stamping dies play a vital role in the stamping process. Without suitable matrices,...

Robotic Arm Printing: The Definitive Guide

The stamping robotic arm is a crucial component of smart manufacturing. Automatic stamping dies play a vital role in the stamping process. Without suitable matrices,...

Explore the differences: forging, stamping and ...

Forging, on the other hand, is similar to making burgers out of dough. You knead small balls of dough, place them in a mold and create products of different shapes....

Explore the differences: forging, stamping and ...

Forging, on the other hand, is similar to making burgers out of dough. You knead small balls of dough, place them in a mold and create products of different shapes....

Extending the Life of High-Quality Die Casting ...

⑵ After forging, adopt air cooling control and timely place it in the annealing furnace for post-forging heat treatment at about 400°C. The heating temperature for...

Extending the Life of High-Quality Die Casting ...

⑵ After forging, adopt air cooling control and timely place it in the annealing furnace for post-forging heat treatment at about 400°C. The heating temperature for...

Dies for Automotive Stamping: Development and C...

1. Body process data release The body design department releases product simulation models, and the engineering personnel of the engineering development department...

Dies for Automotive Stamping: Development and C...

1. Body process data release The body design department releases product simulation models, and the engineering personnel of the engineering development department...