I. Working principle and maintenance of punching machines

1. Working principle of punching machines:

Most of the punching machines we use today belong to this category, which is widely used because of its simple mechanical structure, reliable mechanical performance and precision.

With the continuous development of science and technology, some modern punching machines have integrated “mechanical, electrical, pneumatic, hydraulic” systems and numerical control structures.

They are more reliable in operation, have higher stamping accuracy, more comprehensive functions and more reliable safety performance.

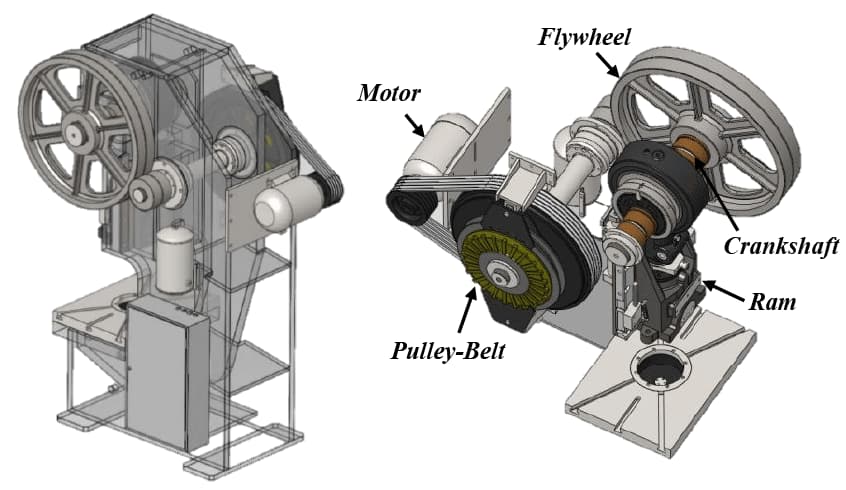

The machining accuracy of a punch press is related to the clearances between the slide and the sliding guide rail (generally with a standard comprehensive clearance of 0.02-0.13) and the deformation of the punch body during operation (especially for punch press type C presses, where the standard deviation between the centerline of the slider and the centerline of the worktable should not be more than 3′), as well as the parallelism between the lower plane of the carriage and the working surface of the worktable , clearances between the slide and the connecting rod, clearances between the connecting rod and the crankshaft and the central vibration of the flywheel.

Based on the above points, the daily/shift inspection and annual inspection of the punch press should reflect these aspects, and the content related to these inspection items should also be reflected in the daily inspection. For example, oil condition, noise, vibration, body tremors, 2S, etc.

III. Stamping machine correction

1. Clearance between slide and guide rail

Adjusting the clearance between the slide and guide rail is mainly for accuracy. If adjusted too tightly, it will generate heat.

Generally, for small machines, the gap on each side is between 0.02 ~ 0.05mm, while for large machines, the gap on each side should be between 0.03 ~ 0.20mm.

2. General release

The corrective method for general backlash is as follows: During production, touch the movable slide body with your hand. If there is a feeling of vibration when the slide reaches bottom dead center, it means that the overall clearance is too large and needs to be adjusted in a timely manner.

3. Slide link lock

Due to prolonged use or overload, the connection may become loose. This condition is generally considered overload. In addition, if oil leaks from the joint, it may also be caused by overloading.

In this case, the locking degree of the connecting rod locknut must be adjusted in a timely manner, as it is related to safety issues.

4. Brake and Clutch Maintenance

The brake and clutch of a stamping machine are important components for the safe operation of the machine. They are the cause of major safety accidents, so it is necessary to understand their basic structure and confirm their safety performance before daily operation.

If any abnormal conditions are found (such as the slide cannot stop at the specified position, abnormal sound during operation, abnormal vibration, slow movement of the slide, etc.), report them immediately for maintenance.

Additionally, maintenance personnel should also pay attention to signs of excessive play between the brake and clutch friction plates.

These signs include increased use of compressed air, crawling of the stamping machine slide, and in severe cases, continuous movement of the slide during a single operation, which is absolutely prohibited.

If the clearance is set too small, the brake and clutch friction plates will emit rubbing noise, generate heat, and cause an increase in motor current, which may damage the return spring. (The normal gap standard is 1.5 ~ 3.0mm.)

5. Non-involvement

Disengagement usually occurs at bottom dead center when the upper and lower dies are closed, causing the slide to not operate normally.

At this time, the engine can be reversed and air pressure can be increased to raise the slide in small increments to top dead center by selecting “inch” mode on the operating selector.

6. Fixing loose screws

It is necessary to regularly check the screws of machine tool accessories, especially for some stamping machines that operate at high speeds and frequencies.

These machines are prone to vibrations, which can easily cause screws to loosen. Once the screws loosen, if not corrected in time, unexpected safety accidents may occur.

7. Lubrication System Inspection

Mechanical moving parts can often cause burns or bites if lubrication is not timely, so it is necessary to carry out inspection of the oil supply part.

This includes checking the oil cups, oil tanks, oil pipes, filters, oil seals, etc. for “running, leaking, dripping, blocking and other phenomena” and dealing with them in a timely manner.

8. Compressed Air Inspection

When the compressed air pipeline of the machine tool leaks, it will cause a decrease in pressure and affect the operation of the machine tool, causing it to malfunction, so it must be repaired immediately.

Furthermore, the water content of the compressed air must also be controlled (an air filtration drying and dehumidification device can be installed). This is one of the main causes of slow movement and corrosion of electromagnetic valves, cylinders and other machine tool devices.

9. Periodic Inspection of Stamping Machine Accuracy

The precision of the stamping machine directly affects the service life of the mold and the processing accuracy of the product. However, as time passes, the machine tool precision of the stamping machine deteriorates.

Therefore, it is necessary to carry out periodic precision inspections, discover problems in a timely manner and repair them to ensure that the machine tool has relatively accurate precision, thereby ensuring the precision of the products produced.

For inspection, maintenance and correction of machine tools, each schedule must begin and end with 2S. That is, before inspection and maintenance, clean and clean all parts of the machine tool, especially some very dirty areas.

Also, observe whether there are any abnormal conditions during cleaning and record them one by one.

After inspection and maintenance, immediately clean around the machine table and count the tools to avoid leaving tools, rags and other items inside the machine, which may cause unnecessary danger to the operation and safety of the machine.