The color temperature of steel is closely related to the heating process. At room temperature, steel does not emit light. However, when heated to a certain temperature, it begins to glow, initially emitting a red light. As the temperature increases further, the color of the steel gradually changes from red to orange and then to yellow.

This process is aligned with the concept of blackbody radiation, where color temperature is defined based on blackbody radiation, with orange-yellow having a lower color temperature and blue having a higher color temperature. .

Specifically for steel, when its color temperature reaches 3,200K, the color of light becomes relatively close to red, which is the color of iron when heated to more than a thousand degrees.

If heating continues, the glow will become stronger and the color will become closer to white.

This indicates that by controlling the heating process, a color change from red to almost white can be achieved.

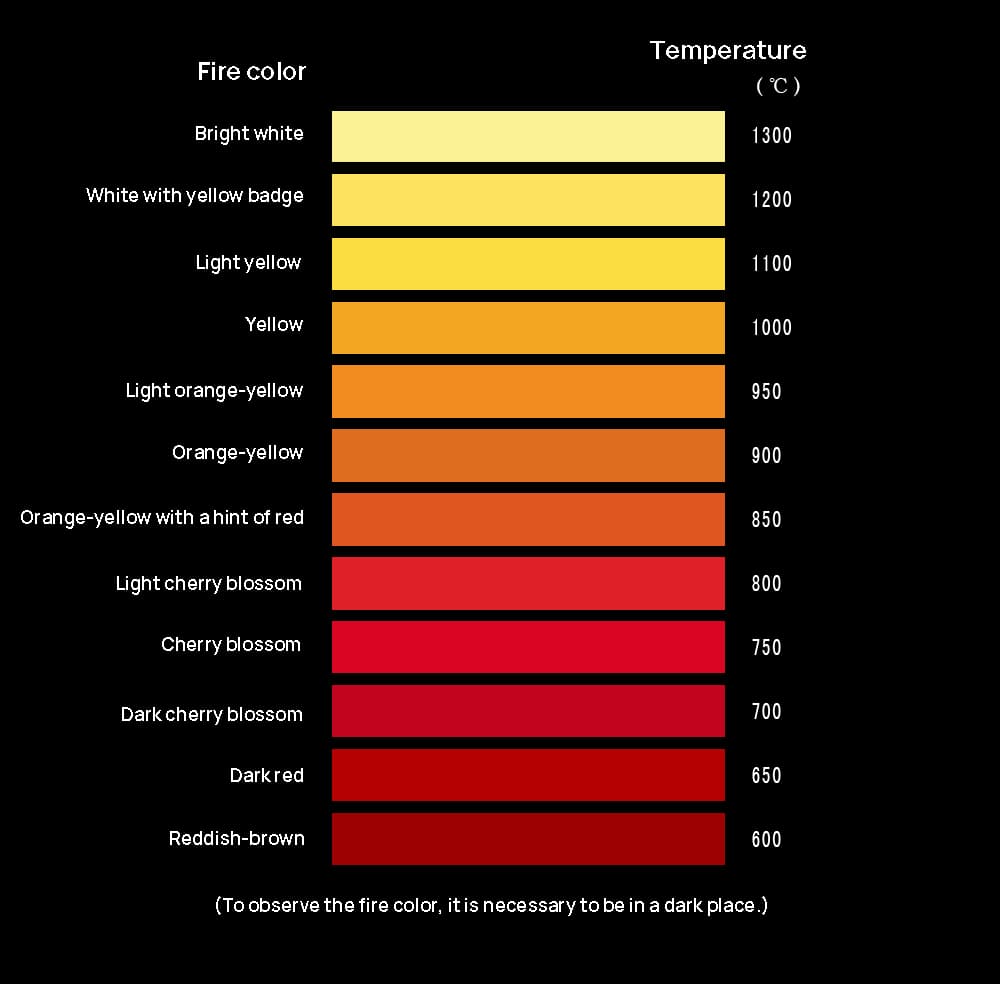

- At around 600 degrees Celsius, a faint red color begins to appear

- At 700 degrees Celsius, it turns into a light orange color

- At 800 degrees Celsius, it turns red

- At 900 degrees Celsius, it turns yellowish-red

- At 1000 degrees Celsius, it turns a whitish-red color

This is not an accurate method and may vary depending on the type of steel used. These colors are only applicable for certain types of steels (probably carbon steel). The flame color may be different for different types of metals at the same temperature.

The relationship between the heating temperature of steel and its color:

In 1893, Wien studied the relationship between the maximum wavelength λmax and the temperature T, which is λmax . T=2898μ l •K .

Therefore, temperature can be judged based on the color of the flame (i.e., the wavelength of the light).

Empirical observation shows that dark red indicates 600°C, red indicates 900°C, orange-yellow indicates 1100°C, yellow indicates 1300°C, light yellow indicates 1400°C, yellow-white indicates 1500° C and bright white (with a hint of yellow) indicates 1600°C.

There is a type of temperature-sensitive paper developed by Nichiyu Giken Kogyo Co., Ltd. that can be placed on heated metal to show its temperature changes through different colors.

By observing the color changes of the paper on different parts of the metal, one can determine their respective temperatures and record them accordingly to make a color chart for later use.

The relationship between the color of steel heating and temperature

| color of fire | Temperature ℃ |

| Dark brown | 520——580 |

| Dark red | 580——650 |

| Dark cherry | 650——750 |

| Cherry Blossom | 750——780 |

| Light cherry blossom | 780——800 |

| Red light | 800——830 |

| Orange yellow with a touch of red | 830——850 |

| Faded light | 880——1050 |

| Yellow | 1050——1150 |

| Yellow light | 1150——1250 |

| Yellowish white | 1250——1300 |

| Bright white | 1300——1350 |

The relationship between tempering color and temperature of carbon steel.

| Tempered color | Temperature ℃ |

| Yellow light | 200 |

| Yellowish white | 220 |

| golden yellow | 240 |

| Yellow-purple | 260 |

| Dark purple | 280 |

| Blue | 300 |

| Dark blue | 320 |

| Bluish gray | 340 |

| Light blue-gray white | 370 |

| Black red | 400 |

| Black | 460 |

| Black dark | 500 |

This seems to require a lot of experience, as temperatures can be different during the day and night. The thermometer is not always easy to use and may not be very accurate.

There may also be differences between the temperature of the flame and the temperature of the object being measured.

How to accurately measure the color temperature of steel?

There are several methods to accurately measure the color temperature of steel:

1. Color Temperature Meter:

A color temperature meter is a tool used specifically to measure the color temperature of a light source. Its use is similar to that of a photometer, mainly due to the placement of the measuring probe on the object to be measured. This method is suitable for directly measuring the intensity of all wavelengths of light emitted by the light source, thus obtaining the color temperature value.

2. Spectral Analysis:

Spectral analysis measures color temperature by directly measuring the intensity of the entire wavelength of light emitted by the light source. This method can provide more detailed spectral information, helping to accurately assess the color temperature of steel.

3. Colorimeter:

A colorimeter is another tool used specifically to measure the color temperature of a light source, including filter type and crystal type. Filter-type colorimeter measures color temperature by filtering light of specific wavelength, while crystal-type colorimeter determines color temperature by measuring the crystal's response to different wavelengths of light.

Accurate measurement of the color temperature of steel can be achieved using a color temperature meter, spectral analysis or colorimeter. The choice of method depends on the specific measurement requirements and available resources. For example, if you need to get results quickly and the accuracy requirement is not too high, you can choose a color temperature meter; if more detailed spectral information is required for in-depth analysis, spectral analysis may be more appropriate; and if you have very high requirements for the accuracy of measurement results, consider using a colorimeter for accurate measurements.

What are the detailed changes in the luminescent properties of steel at different temperatures?

The detailed changes in the luminescent properties of steel at different temperatures can be understood from several aspects. Firstly, when the metal reaches a certain temperature, the movement of its internal particles becomes violent, which can cause photons to reach the minimum frequency of visible light, thus producing red luminescence. This indicates that at lower temperatures the steel may not shine or the light intensity may be weak, as the change in electron energy levels is not sufficient to produce visible light.

As the temperature increases, the luminescence intensity of the phosphor will decrease due to the thermal quenching phenomenon. This phenomenon is mainly due to the increase in temperature causing the vibration of the matrix network to intensify, increasing the electroacoustic interaction and the probability of non-radiative transition, thus reducing the light intensity. Although phosphors are mentioned here, this principle also applies to metallic materials such as steel, and a decrease in luminescence intensity can be observed at high temperatures.

Furthermore, from the perspective of luminescence studies, changes in temperature have a significant impact on refrigeration efficiency, and this impact has a cubic relationship with temperature. This means that as the temperature decreases, the difference between the ideal frequency of the excitation light and the center frequency of the non-uniform line shape will increase, reaching a maximum at lower temperatures. This indicates that under low temperature conditions, the luminescent properties of steel may vary due to excitation at specific frequencies, especially at low temperatures where it may be easier to observe luminescence at specific wavelengths.

The luminescent properties of steel will change at different temperatures as follows: at lower temperatures, due to insufficient change in electron energy levels to produce visible light, the steel may not glow or the light intensity may be weak; as the temperature increases, due to the intensification of lattice vibrations and the increase in electroacoustic interaction, the intensity of the steel's luminescence may decrease; and under low temperature conditions, excitation at specific frequencies can cause steel to exhibit different luminescent properties, especially at low temperatures where it may be easier to observe luminescence at specific wavelengths.

What is the relationship between color temperature and blackbody radiation theory during the steel heating process?

The relationship between color temperature and blackbody radiation theory during the steel heating process can be explained from the following aspects:

Definition of color temperature: Color temperature is a scale that measures the color of a light source and its unit is Kelvin. It is determined by comparing the color of the light source with a theoretical blackbody with thermal radiation. The Kelvin temperature at which the thermal radiant blackbody matches the color of the light source is the color temperature of that source.

Blackbody Radiation Theory: A blackbody is an idealized object that can absorb all the radiation energy falling on it without loss and can radiate energy in the form of electromagnetic waves. Planck's law describes the theoretical distribution of wavelengths in blackbody radiation, that is, as the temperature changes, the color of the light also changes.

The color temperature changes during the steel heating process: During the iron heating process, black iron gradually turns red. This is because as the temperature increases, the blackbody can emit all visible light waves in the spectrum, leading to color change. This process is an example of blackbody theory, illustrating the relationship between color temperature and temperature changes during the heating process of an object.

In practical applications, how do we select the appropriate steel material based on color temperature?

In practical applications, selecting suitable steel materials based on color temperature requires consideration of multiple factors. For example, in street lighting design, choosing steel materials with a suitable color temperature can increase the effectiveness of road lighting, making roads safer and easier to navigate. If the steel used in public lighting has a high color temperature (cold tones), it can provide a clearer field of vision, but at the same time it can reduce the heat of the night environment. On the contrary, steel with a low color temperature (warm tones) can increase the heat of the environment, but can affect visibility.

Furthermore, the choice of thermoforming temperature is crucial to guarantee the quality of the formed parts. Different steel materials have different temperature-mechanical property curves, which means that the physical state of the steel changes during the heating process, affecting its final shape and quality. Therefore, when choosing steel materials, it is also necessary to consider the heat treatment requirements during their processing to ensure that the material can meet the specific demands of the application without sacrificing performance.

When selecting suitable steel materials based on color temperature, it is important to consider the material's visual effects, its physical and chemical properties, and heat treatment requirements during its processing. By carefully evaluating these factors, you can choose the steel material that best meets your specific application requirements.

What are some specific examples of the impact of steel color temperature on product performance?

The impact of steel color temperature on product performance is mainly reflected in the following aspects:

1. Mold steel heat treatment process:

The color of mold steel does not change at low temperatures, but when heated to about 600 ℃ and above, a slight dark red color appears. As the temperature increases, the color of the mold steel gradually changes. This shows that the change in the color temperature of steel is related to the change in performance during the heat treatment process, and the color change indirectly reflects the changes in the internal structure and performance of the material.

2. Changes in the strength and plasticity of steel:

An increase in temperature leads to a reduction in the strength of the steel and an increase in deformation. Especially near 250℃, the tensile strength of steel increases, but the plasticity and toughness decrease, while a blue brittleness phenomenon occurs, that is, the oxide film turns blue. This phenomenon shows that the change in color temperature of steel at a specific temperature (such as the color change of oxide film) is closely related to changes in mechanical performance, especially changes in tensile strength, plasticity and toughness.