Regarding the construction site of relevant construction projects, what everyone should know today is about the use of construction materials in the current construction market.

There is no doubt that the two most commonly used construction materials are actually Z-section steel purlin and C-section steel purlin.

Two types of construction materials, Z-section steel and C-section steel, have been developed and put into use in recent years, and Z-section steel and C-section steel have been widely used in the construction industry soon after being introduced due to their low carbon and durability.

In the field of construction industry currently involved, there is a large amount of data on the use of steel in the specific construction process.

Furthermore, as the current Z-section steel purlin and C-section steel purlin have greatly replaced the status of some more traditional building materials in a certain sense, it has actually created a large number of Z-section and C-section steel - steel section to some extent.

Difference between C third and Z third

| Aspect | C Section Steel Purlin | Z-section steel purlin |

|---|---|---|

| Included Angle | 90 degrees | 60-75 degrees |

| Mechanical properties | Different strong and weak axis properties | More balanced mechanical properties |

| Connection to the steel structure | Generally bolted connection; considered as simple support | Often preferred due to better voltage distribution |

| Preferred use based on roof pitch | Preferred for wall purlins and low-slope roofs | Preferred for steeply pitched roofs |

| Section module in roof slope | A little smaller compared to the Z motherboard | Increases symmetrically for steeper slopes |

| Choice for walls | Comparable to Z third | Comparable to third C |

| Continuous Structural Members | Less suitable for overlapping | Best suited due to ease of layering |

| General use | Widely used in various applications | Preferred in specific situations due to its advantages |

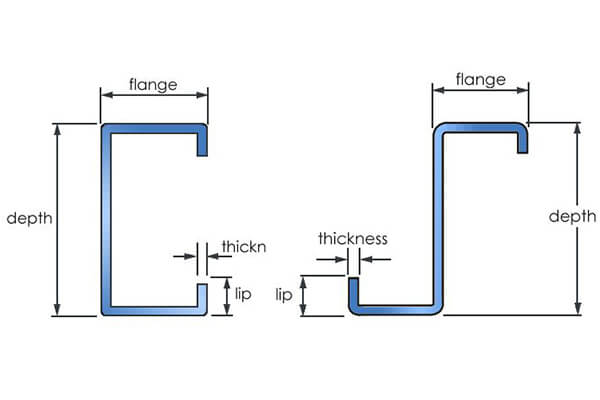

To understand the essential difference between C section steel purlin and Z section steel purlin, we need to have a corresponding understanding of C/Z section steel purlin

Next, I will talk about C-section steel purlin and Z-section steel purlin, respectively, and then analyze their essential differences according to the understanding of their use.

The angle between the C-shaped steel purlin and the Z-shaped steel purlin is different.

The included angle of the C-shaped steel purlin is 90 degrees, and the included angle of the Z-shaped steel purlin is less than 90 degrees, about 60-75 degrees.

Therefore, the included purlin angle must be considered in the selection and combined with the corresponding stress knowledge.

Compared with the Z third, the mechanical properties of the strong and weak axes of the C third are very different

The connection between the C section steel and the steel structure generally adopts bolted connection, which should be considered as simple support in the calculation, so the latter is more reasonable in stress, calculation results and structure.

Therefore, in addition to other special processing needs such as door and window openings, Z-shaped steel section should be preferred, and C-shaped steel should be preferred for wall purlins and house purlins with small slope ;

The purlin of the steeply pitched roof should be Z-shaped.

What type of Tuesday should be used in which environment? This is useful for choosing construction materials.

1. When the roof slope is small, the section modulus of the Z-shaped steel purlin is slightly larger than that of the C-shaped steel purlin, but the difference is not significant;

When the roof slope increases, the modulus utilization of the Z-shaped steel purlin section increases symmetrically in the vertical direction.

Therefore, the Z-shaped steel purlin is suitable for roofs with a large slope.

2. For the wall, the choice of type Z and type C is not much different.

3. If the purlins want to be continuous structural members, try using Z-shaped steel purlins because they are easy to overlap.

What type of environment and what type of building materials are used in different environments?

The building materials they use perform different functions, but C motherboard is still widely used in today's life.

The above is an essential difference between C/Z steel purlins for everyone to understand.

Tuesday C

C section steel is automatically processed and formed by C section steel forming machine.

The machine can automatically complete the forming process according to the given size.

C section steel is processed by cold bending into hot coil, with thin wall, light weight, excellent section performance and high strength.

Compared with traditional steel channel, the same strength can save 30% of materials.

C Section Steel Application

C-section steel is widely used in purlins and wall beams of steel frame buildings, and can also be combined into lightweight roof trusses, supports and other building components.

Furthermore, it can also be used in columns, beams and arms in mechanical and light industrial manufacturing.

C third processing flow

Unload ① – level ② – shape ③ – adjust ④ – straighten ⑤ – measure the length ⑥ – drill the round hole of the connecting bar ⑦ – drill the elliptical connecting hole ⑧ – form and cut ⑨

Specification Type

C-shaped steel purlins are divided into five specifications: 80, 100, 120, 140 and 160 according to different heights.

The length can be determined according to the engineering design, but considering conditions such as transportation and installation, the total length generally does not exceed 12m.

C Tuesday Weight Chart

Meaning of numbers in each line (take C80×40×20×2.5 as an example):

- Section height h=80mm;

- Section width b=40mm;

- Crimping width c=20mm;

- Thickness t=2.5mm;

| Model |

Sizes (mm) |

Cross-sectional area (cm²) |

Weight (kg/m) |

|||

|---|---|---|---|---|---|---|

| H | B | w | t | |||

| C80 | 80 | 40 | 20 | 2.25 | 4.29 | 3.37 |

| C80 | 80 | 40 | 20 | 2.50 | 4.75 | 3.72 |

| C80 | 80 | 40 | 20 | 2.75 | 5.19 | 4.08 |

| C80 | 80 | 40 | 20 | 3:00 | 5.64 | 4.42 |

| C80 | 80 | 50 | 20 | 2.25 | 4.74 | 3.72 |

| C80 | 80 | 50 | 20 | 2.50 | 5.25 | 4.12 |

| C80 | 80 | 50 | 20 | 2.75 | 5.74 | 4.51 |

| C80 | 80 | 50 | 20 | 3:00 | 6.24 | 4.89 |

| C100 | 100 | 50 | 20 | 2.25 | 5.19 | 4.08 |

| C100 | 100 | 50 | 20 | 2.50 | 5.75 | 4.51 |

| C100 | 100 | 50 | 20 | 2.75 | 6.29 | 4.94 |

| C100 | 100 | 50 | 20 | 3:00 | 6.84 | 5.36 |

| C120 | 120 | 50 | 20 | 2.25 | 5.64 | 4.43 |

| C120 | 120 | 50 | 20 | 2.50 | 6.25 | 4.90 |

| C120 | 120 | 50 | 20 | 2.75 | 6.84 | 5.37 |

| C120 | 120 | 50 | 20 | 3:00 | 7.44 | 5.84 |

| C140 | 140 | 50 | 20 | 2.25 | 6.09 | 4.78 |

| C140 | 140 | 50 | 20 | 2.50 | 6.75 | 5.29 |

| C140 | 140 | 50 | 20 | 2.75 | 7.39 | 5.80 |

| C140 | 140 | 50 | 20 | 3:00 | 8.03 | 6.31 |

| C140 | 140 | 60 | 20 | 2.25 | 6.54 | 5.13 |

| C140 | 140 | 60 | 20 | 2.50 | 7:25 am | 5.69 |

| C140 | 140 | 60 | 20 | 2.75 | 7.94 | 6.23 |

| C140 | 140 | 60 | 20 | 3:00 | 8.64 | 6.78 |

| C160 | 160 | 50 | 20 | 2.25 | 6.54 | 5.13 |

| C160 | 160 | 50 | 20 | 2.50 | 7:25 am | 5.69 |

| C160 | 160 | 50 | 20 | 2.75 | 7.94 | 6.23 |

| C160 | 160 | 50 | 20 | 3:00 | 8.64 | 6.78 |

| C160 | 160 | 60 | 20 | 2.25 | 6.99 | 5.49 |

| C160 | 160 | 60 | 20 | 2.50 | 7.75 | 6.08 |

| C160 | 160 | 60 | 20 | 2.75 | 8.49 | 6.67 |

| C160 | 160 | 60 | 20 | 3:00 | 9.24 | 7:25 am |

| C160 | 160 | 70 | 20 | 2.25 | 7.44 | 5.84 |

| C160 | 160 | 70 | 20 | 2.50 | 8:25 am | 6.47 |

| C160 | 160 | 70 | 20 | 2.75 | 9.04 | 7.10 |

| C160 | 160 | 70 | 20 | 3:00 | 9.84 | 7.72 |

| C180 | 180 | 50 | 20 | 2.25 | 6.99 | 5.49 |

| C180 | 180 | 50 | 20 | 2.50 | 7.75 | 6.08 |

| C180 | 180 | 50 | 20 | 2.75 | 8.49 | 6.67 |

| C180 | 180 | 50 | 20 | 3:00 | 9.24 | 7:25 am |

| C180 | 180 | 60 | 20 | 2.25 | 7.44 | 5.84 |

| C180 | 180 | 60 | 20 | 2.50 | 8:25 am | 6.47 |

| C180 | 180 | 60 | 20 | 2.75 | 9.04 | 7.10 |

| C180 | 180 | 60 | 20 | 3:00 | 9.84 | 7.72 |

| C180 | 180 | 70 | 20 | 2.25 | 7.89 | 6.19 |

| C180 | 180 | 70 | 20 | 2.50 | 8.75 | 6.86 |

| C180 | 180 | 70 | 20 | 2.75 | 9.59 | 7.53 |

| C180 | 180 | 70 | 20 | 3:00 | 10.44 | 8.19 |

| C180 | 180 | 80 | 20 | 2.25 | 8.34 | 6.55 |

| C180 | 180 | 80 | 20 | 2.50 | 9:25 am | 7.26 |

| C180 | 180 | 80 | 20 | 2.75 | 10.14 | 7.96 |

| C180 | 180 | 80 | 20 | 3:00 | 11.04 | 8.66 |

| C200 | 200 | 50 | 20 | 2.25 | 7.44 | 5.84 |

| C200 | 200 | 50 | 20 | 2.50 | 8:25 am | 6.47 |

| C200 | 200 | 50 | 20 | 2.75 | 9.04 | 7.10 |

| C200 | 200 | 50 | 20 | 3:00 | 9.84 | 7.72 |

| C200 | 200 | 60 | 20 | 2.25 | 7.89 | 6.19 |

| C200 | 200 | 60 | 20 | 2.50 | 8.75 | 6.86 |

| C200 | 200 | 60 | 20 | 2.75 | 9.59 | 7.53 |

| C200 | 200 | 60 | 20 | 3:00 | 10.44 | 8.19 |

| C200 | 200 | 70 | 20 | 2.25 | 8.34 | 6.55 |

| C200 | 200 | 70 | 20 | 2.50 | 9:25 am | 7.26 |

| C200 | 200 | 70 | 20 | 2.75 | 10.14 | 7.96 |

| C200 | 200 | 70 | 20 | 3:00 | 11.04 | 8.66 |

| C200 | 200 | 80 | 20 | 2.25 | 8.79 | 6.90 |

| C200 | 200 | 80 | 20 | 2.50 | 9.75 | 7.65 |

| C200 | 200 | 80 | 20 | 2.75 | 10.69 | 8.39 |

| C200 | 200 | 80 | 20 | 3:00 | 11.64 | 9.13 |

| C220 | 220 | 50 | 20 | 2.25 | 7.89 | 6.19 |

| C220 | 220 | 50 | 20 | 2.50 | 8.75 | 6.86 |

| C220 | 220 | 50 | 20 | 2.75 | 9.59 | 7.53 |

| C220 | 220 | 50 | 20 | 3:00 | 10.44 | 8.19 |

| C220 | 220 | 60 | 20 | 2.25 | 8.34 | 6.55 |

| C220 | 220 | 60 | 20 | 2.50 | 9:25 am | 7.26 |

| C220 | 220 | 60 | 20 | 2.75 | 10.14 | 7.96 |

| C220 | 220 | 60 | 20 | 3:00 | 11.04 | 8.66 |

| C220 | 220 | 70 | 20 | 2.25 | 8.79 | 6.90 |

| C220 | 220 | 70 | 20 | 2.50 | 9.75 | 7.65 |

| C220 | 220 | 70 | 20 | 2.75 | 10.69 | 8.39 |

| C220 | 220 | 70 | 20 | 3:00 | 11.67 | 9.13 |

| C220 | 220 | 80 | 20 | 2.25 | 9.24 | 7:25 am |

| C220 | 220 | 80 | 20 | 2.50 | 10:25 am | 8.04 |

| C220 | 220 | 80 | 20 | 2.75 | 11.24 | 8.82 |

| C220 | 220 | 80 | 20 | 3:00 | 12.24 | 9.60 |

| C240 | 240 | 50 | 20 | 2.25 | 8.34 | 6.55 |

| C240 | 240 | 50 | 20 | 2.50 | 9:25 am | 7.26 |

| C240 | 240 | 50 | 20 | 2.75 | 10.14 | 7.96 |

| C240 | 240 | 50 | 20 | 3:00 | 11.04 | 8.66 |

| C240 | 240 | 60 | 20 | 2.25 | 8.79 | 6.90 |

| C240 | 240 | 60 | 20 | 2.50 | 9.75 | 7.65 |

| C240 | 240 | 60 | 20 | 2.75 | 10.69 | 8.39 |

| C240 | 240 | 60 | 20 | 3:00 | 11.64 | 9.13 |

| C240 | 240 | 70 | 20 | 2.25 | 9.24 | 7:25 am |

| C240 | 240 | 70 | 20 | 2.50 | 10:25 am | 8.04 |

| C240 | 240 | 70 | 20 | 2.75 | 11.24 | 8.82 |

| C240 | 240 | 70 | 20 | 3:00 | 12.24 | 9.60 |

| C240 | 240 | 80 | 20 | 2.25 | 9.69 | 7.61 |

| C240 | 240 | 80 | 20 | 2.50 | 10.75 | 8.43 |

| C240 | 240 | 80 | 20 | 2.75 | 11.79 | 9.26 |

| C240 | 240 | 80 | 20 | 3:00 | 12.84 | 10.07 |

| C250 | 250 | 50 | 20 | 2.25 | 8.57 | 6.72 |

| C250 | 250 | 50 | 20 | 2.50 | 9:50 am | 7:45 am |

| C250 | 250 | 50 | 20 | 2.75 | 10.42 | 8.18 |

| C250 | 250 | 50 | 20 | 3:00 | 11:34 am | 8.90 |

| C250 | 250 | 60 | 20 | 2.25 | 9.02 | 7.08 |

| C250 | 250 | 60 | 20 | 2.50 | 10:00 | 7.85 |

| C250 | 250 | 60 | 20 | 2.75 | 10.97 | 8.61 |

| C250 | 250 | 60 | 20 | 3:00 | 11.94 | 9:37 am |

| C250 | 250 | 70 | 20 | 2.25 | 9:47 am | 7.43 |

| C250 | 250 | 70 | 20 | 2.50 | 10:50 am | 8.24 |

| C250 | 250 | 70 | 20 | 2.75 | 11.52 | 9.04 |

| C250 | 250 | 70 | 20 | 3:00 | 12.54 | 9.84 |

| C250 | 250 | 75 | 20 | 2.25 | 9.69 | 7.61 |

| C250 | 250 | 75 | 20 | 2.50 | 10.75 | 8.43 |

| C250 | 250 | 75 | 20 | 2.75 | 11.79 | 9.26 |

| C250 | 250 | 75 | 20 | 3:00 | 12.84 | 10.07 |

| C250 | 250 | 80 | 20 | 2.25 | 9.92 | 7.78 |

| C250 | 250 | 80 | 20 | 2.50 | 11:00 | 8.63 |

| C250 | 250 | 80 | 20 | 2.75 | 12.07 | 9:47 am |

| C250 | 250 | 80 | 20 | 3:00 | 13.14 | 10:31 am |

C Tuesday Weight Calculator

Z Tuesday

Z-section steel is a common cold-formed thin-walled section steel with a thickness of 1.6-3.0mm and a section height of 120-350mm.

Processing materials are hot-rolled (painted) and galvanized.

The processing standard must be in accordance with GB50018-2002.

Z-section steel is generally used in large steel structure factories.

The processing length and hole are produced according to the processing requirements.

Z Section Steel Purlin Applications

Cold-formed Z-shaped steel has the advantages of adjustable specification and size and strong compressive strength.

It is widely used in automobile, railway vehicle, construction doors and windows, transportation, shelf, electrical cabinet, highway guardrail, steel structure construction, container, steel formwork and scaffolding, solar support shipbuilding, bridge, power transmission tower, steel sheet piling, cable bridge, agricultural machinery, furniture, storage, guide rail, steel keel Vegetable greenhouses, pipe supports, municipal construction fields etc.

Z Tuesday Weight Chart

| No | Item | Model | Unit | Weight |

|---|---|---|---|---|

| 1 | Cold Bending Z Section Steel | Z80×40×2.5 | kg/m | 2,947 |

| two | Cold Bending Z Section Steel | Z80×40×3.0 | kg/m | 3,491 |

| 3 | Cold Bending Z Section Steel | Z100×50×2.5 | kg/m | 3,732 |

| 4 | Cold Bending Z Section Steel | Z100×50×3.0 | kg/m | 4,432 |

| 5 | Z Purlin Cold Bend Steel | Z100×40×20×2.0 | kg/m | 3,208 |

| 6 | Z Purlin Cold Bend Steel | Z100×40×20×2.5 | kg/m | 3,932 |

| 7 | Z Purlin Cold Bend Steel | Z120×50×20×2.0 | kg/m | 3,835 |

| 8 | Z Purlin Cold Bend Steel | Z120×50×20×2.5 | kg/m | 4,718 |

| 9 | Z Purlin Cold Bend Steel | Z120×50×20×3.0 | kg/m | 5,569 |

| 10 | Z Purlin Cold Bend Steel | Z140×50×20×2.5 | kg/m | 5.11 |

| 11 | Z Purlin Cold Bend Steel | Z140×50×20×3.0 | kg/m | 6.04 |

| 12 | Z Purlin Cold Bend Steel | Z160×60×20×2.5 | kg/m | 5,895 |

| 13 | Z Purlin Cold Bend Steel | Z160×60×20×3.0 | kg/m | 6,982 |

| 14 | Z Purlin Cold Bend Steel | Z160×70×20×2.5 | kg/m | 6,288 |

| 15 | Z Purlin Cold Bend Steel | Z160×70×20×3.0 | kg/m | 7,453 |

| 16 | Z Purlin Cold Bend Steel | Z180×70×20×2.5 | kg/m | 6,679 |

| 17 | Z Purlin Cold Bend Steel | Z180×70×20×3.0 | kg/m | 7,924 |

| 18 | Z Purlin Cold Bend Steel | Z200×70×20×2.5 | kg/m | 7,073 |

| 19 | Z Purlin Cold Bend Steel | Z200×70×20×3.0 | kg/m | 8,394 |

| 20 | Z Purlin Cold Bend Steel | Z230×75×25×3.0 | kg/m | 9,573 |

| 21 | Z Purlin Cold Bend Steel | Z230×75×25×4.0 | kg/m | 12.51 |

| 22 | Z Purlin Cold Bend Steel | Z250×75×25×3.0 | kg/m | 10.04 |

| 23 | Z Purlin Cold Bend Steel | Z250×75×25×4.0 | kg/m | 13.14 |