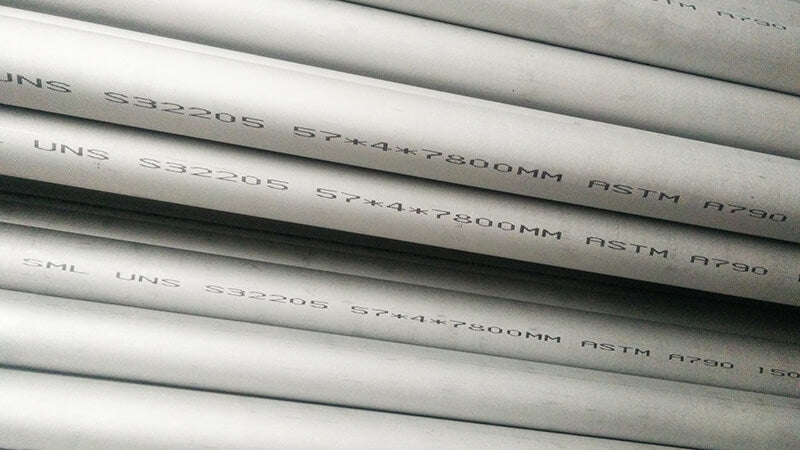

SAF Duplex 2205 Stainless Steel Alloy Material (UNS S32205 S31803)

SAF Duplex 2205 stainless steel (UNS S32205 formerly known as UNS S31803 and commonly known as “alloy 2205”) has a mixed microstructure of austenite and ferrite and is a two-phase alloy based on the Fe-Cr-Ni series. Alloy 2205 material has lower nickel and molybdenum content than austenitic stainless steel and has similar corrosion resistance. Because the price of Ni and Mo is relatively high, 2205 duplex stainless steel is often considered an economical alternative to austenitic stainless steel.

Compared with conventional 300 series stainless steel (e.g. SS 304, SS 316, SS 301, SS 904L and 303, etc.), the special advantages of 2205 duplex stainless steel are strength (about twice that of austenitic stainless steel) and excellent resistance to SCC chloride and pitting corrosion. High yield strength has sufficient pressure and bearing capacity, and thin-walled materials can be made to greatly reduce weight.

Duplex 2205 Datasheet and Specifications

The following tables present the technical sheet and specifications of SAF 2205 duplex stainless steel, such as chemical composition, physical properties, mechanical properties, heat treatment, welding, etc.

Chemical composition

The following table lists the chemical composition of alloy 2205 stainless steel based on casting analysis.

| Chemical composition, % | |||||||||||

| Country | Steel Grade (UNS) | Standard | C, ≤ | Yes, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | No | Mo | N |

| USA | 2205 (UNS S32205, UNS S31803) | ASTM A276/A276M; ASTM A240/A240M | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

Physical properties

Grades:

- 1g/cm3 = 1kg/dm3 = 1000kg/m3;

- 1 μΩ·m = 1 Ω·mm²/m

- 1 GPa = 1kN/mm2

| Physical properties | |

| Density, g/cm3 (lb/in3) | 7.83 (0.283) |

| Melting point, ℃ (°F) | 1385-1440 (2525-2630) |

| Magnetic | Yes |

| Electrical resistivity, μΩ·m | 0.85 (20℃) (68°F) |

| 0.90 (100℃) (212°F) | |

| 0.95 (200℃) (392°F) | |

| 1.0 (300℃)(572°F) | |

| Specific heat capacity, J/(kg·K) | 470 (20℃) (68°F) |

| 500 (100℃) (212°F) | |

| 530 (200℃) (392°F) | |

| 560 (300℃) (572°F) | |

| Thermal conductivity, (W/m·K) | 15.0 (20℃) (68°F) |

| 15.9 (100℃) (212°F) | |

| 17.0 (200℃) (392°F) | |

| 18.0 (300℃) (572°F) | |

| Modulus of elasticity, Gpa | 190 (20℃) (68°F) |

| 180 (100℃) (212°F) | |

| 175 (200℃) (392°F) | |

| 171 (300℃) (572°F) | |

| Average coefficient of thermal expansion, (10-6/K) | 13.5 (20-100℃) (68°F – 212°F) |

| 14.0 (20-200℃) (68°F – 392°F) | |

| 14.6 (20-300℃) (68°F – 572°F) | |

Mechanical properties

Mechanical properties of 2205 duplex stainless steel at room temperature under various conditions and resistance to intergranular corrosion, including yield strength, tensile strength and hardness, etc.

| Mechanical properties | ||||||||

| Country (Region) | Standard | AISI type (UNS) | 0.2% proof strength, MPa (ksi), ≥ | Tensile strength, MPa (ksi), ≥ | Elongation by 50 mm (2 in.), %, ≥ | Brinell hardness (HBW), ≤ | Rockwell hardness (HRC), ≥ | Condition and finish |

| USA | ASTM A276/A276M | 2205 (UNS S32205, UNS S31803) | 450 (65) | 655 (95) | 25 | 290 | – | Annealed, hot finished or cold finished |

| ASTM A240/A240M | 450 (65) | 655 (95) | 25 | 293 | 31 | – | ||

SAF Duplex 2205 Stainless Steel Heat Treatment

The recommended annealing temperature for 2205 duplex stainless steel is 1040℃ (1900°F), the annealing temperature cooling must be rapid, water quenching is preferred, but it must also meet the deformation limits. This treatment is suitable for full solution annealing and stress relief annealing.

Hot Forming

The hot forming temperature range of alloy 2205 material is 1200-955°C (2190-1750°F). It is recommended to carry out complete annealing with rapid cooling after hot forming, preferably water quenching.

Cold Forming

Due to its greater strength, the force required for cold forming SAF 2205 alloy is greater than the typical force of austenitic stainless steel. Thorough annealing and quenching are recommended after severe cold forming.

Welding

SS 2205 duplex can be welded by all common welding processes (except gas welding), such as MMA/SMAW, MIG/GMAW, TIG/GTAW, FCAW, SAW and PAW, and can be welded on carbon steels, low alloy or austenitic. stainless steels, the filler metal can be duplex, super duplex, E2209, E2594, 309L or 309LMo.

- The maximum temperature between passes is 150°C (300°F),

- Preheating is not necessary,

- and post-weld heat treatment is not recommended, if necessary, it should be done at 1040°C (1900°F) minimum, followed by rapid cooling.

Machining

The high strength makes SAF 2205 stainless steel difficult to machine and therefore requires powerful machines and very strong tool holders. The cutting speed should be reduced by approximately 20% from the typical cutting speed of type 316L.

Corrosion resistance

Alloy 2205 (UNS S31803, S32205) has much better corrosion resistance than 304 and SS 316 stainless steel, such as excellent corrosion resistance (PREN = 30.5), superior SCC chloride resistance and abrasion resistance.

Heat resistance

The maximum temperature for 2205 duplex stainless steel applications is generally less than 300°C (570°F) because the high alloy content and presence of a ferrite matrix make it susceptible to embrittlement and reduced mechanical strength, especially tenacity, due to prolonged exposure. at high temperatures.

Uses and applications

Duplex 2205 stainless steel has been widely used in many industries, especially in the oil and gas, petrochemical and pulp and paper industries. They are typically used in chloride-containing aqueous environments and as a replacement for austenitic stainless steels, which are subject to chloride SCC or corrosion during use.

Equivalent grade SAF Duplex 2205

SAF Duplex 2205 stainless steel (UNS S32205, formerly UNS S31803) equivalent to ASTM AISI SAE, ISO, European standard (German DIN, British BSI, French NF), Japanese JIS and Chinese GB (for reference).

| Equivalent grade Duplex 2205 | |||||||||

| USA | European Union | ISO | China | Japan | |||||

| Standard | Note (UNS) | Standard | Steel Name (Material Number) | Standard | Grade (ISO number) | Standard | Note (UNS) | Standard | Note |

| AISI; ASTM A240/A240M; ASTM A276/A276M; |

Duplex 2205 (UNS S32205); UNS S31803 | EN 10088-2; EN 10088-3 |

X2CrNiMoN22-5-3 (1.4462) | ISO 15510 | X2CrNiMoN22-5-3 (4462-318-03-I) | GB/T 1220; GB/T 3280 |

022Cr22Ni5Mo3N (S22293) | JIS G4303; JIS G4304; JIS G4305 | SUS329J3L |