Advent of CMOS technology in the eighties led to the phenomenal growth of the semiconductor industry. Transistors have become smaller, faster, consume less power and are cheaper to manufacture. It is CMOS technology that has allowed very high integration into chips, leading to miniaturized and modern high-performance integrated circuits.

In addition to the valuable contribution in the miniaturization of integrated circuits, CMOS technology has found applications in sensing applications.

Figure 1: An image that represents the use of CMOS technology in various applications

CMOS technology has been adopted to design sensors, especially in the imaging area. Due to the widespread use of CMOS-based image sensors , CMOS sensors are often considered synonymous with CMOS-based image sensors and have emerged as competitors to CCD-based image sensors.

Until recently, Charge Coupled Devices (CCDs) dominated most image detection systems, i.e. cameras, camcorders, etc. CCDs have been used in astronomical cameras, video camcorders, and scanners. However, lately, CMOS imaging has emerged as an alternative to CCD imagers and also offers better features.

The subsequent sections will discuss imagers based on CCD and CMOS sensors, their pros and cons, and also their applications. Furthermore, other applications of CMOS technology in the field of sensing will be discussed.

CMOS versus CCD

The invention of the CCD marked the end of vacuum tube imagers used in television cameras as it overcame the disadvantages of vacuum tubes such as chronic image artifacts such as lag and burn-in, fragility of large glass tubes or sensitivity to shock, vibration and electromagnetic radiation, meticulous work, periodic alignment of pipes, etc. It also ushered in a new era in imaging systems, and for decades enjoyed quality advantages over rival CMOS sensors. Where image quality was paramount, CCDs were preferred, CMOS were mainly used in applications where small size and low power were the main requirements.

With the technological development in CMOS technology, the gap between CCD and CMOS Sensors has narrowed; CMOS sensors can also achieve competitive quality. The choice between CCD and CMOS sensors has become increasingly difficult.

CCD and CMOS image sensors use large arrays of thousands (sometimes millions) of photographic locations, commonly called pixels. Both perform the same steps.

1. Light to charge conversion

The incident light is directed by the microlens (a small lens placed over the pixel to increase its effective size and therefore fill factor) to the photosensitive area of each pixel, where it is converted into electrons that accumulate in a semiconductor “bucket”. .

Figure 2: A figure illustrating the conversion of light to charge

The larger the pixel, the more light it can collect. Thus, large pixel sensors work better in low light conditions. For the same number of pixels, larger pixels result in larger chips, which means higher cost. On the other hand, smaller pixels allow for smaller chip sizes and lower chip prices, as well as lower lens costs. But there are limitations in reducing pixel size. Smaller pixels are less sensitive to light, the optics required to resolve the pixels become expensive and require expensive manufacturing resources.

2. Accumulation of charges

As more light enters, more electrons accumulate in the bucket.

3. Transfer

The accumulated charge must be transferred to the signal conditioning and processing circuit.

4. Charge to Voltage Conversion

The accumulated charge must be output as a voltage signal.

5. Amplification

The voltage signal is then amplified before being fed into the camera circuit.

Both the CMOS and the CCD perform all of these tasks; However, the aspect in which they differ is the order in which these tasks are carried out.

CCD technology summary

BRIEF ABOUT CCD TECHNOLOGY

CCDs were invented in 1969 as a way to store data using bubble memory. In 1974, the first imaging CCD was produced by Fairchild Electronics with a 100×100 pixel format.

The CCD imager consists of two main parts: color filter and pixel array

• Color filter

Microlenses channel light to the photosensitive part of each pixel. Along the way, the photons pass through a set of color filters. The mosaic of these small filters captures color information. Color filters allow separate measurement of red (R), green (G) and blue (B) photons. The color filter filters out unwanted color wavelengths and allows only specific colors of light to pass through a pixel sensor. To achieve this, each pixel is covered by a red, green and blue filter according to a specific standard, such as the Bayer CFA standard.

Fig. 3: A figure demonstrating the Bayer CFA sub-mosaic pattern

The Bayer filter uses 2×2 submosaic patterns with one red, one blue, and two green filters. As the human eye is more sensitive to green light, two green filters are used.

• Pixel matrix

The set of pixels works on the principle of the photoelectric effect and the pixel sensors are responsible for capturing the intensity of the light that passes through. The light intensity data is combined before being converted into an analog voltage signal, which is sent to an external circuit board for further processing.

After the incident light is converted into electrons, the electron charge is accumulated in the same way as a bucket stores water. Pixel charges are read using vertical and horizontal shift registers that act as charge carriers.

How CMOS sensors work

CMOS SENSORS

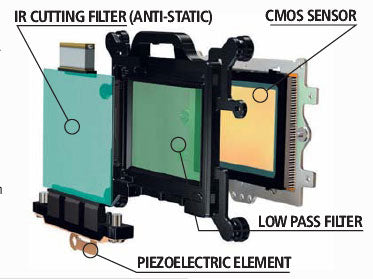

A typical CMOS is an integrated circuit with an array of pixel sensors. In contrast to the CCD, each pixel sensor in CMOS sensors contains its own light sensor, an amplifier and a pixel selection switch. An analog-to-digital converter and other components critical to the operation of the pixel sensors are located on the CMOS sensor.

The CMOS sensor contains four main parts: the color filters, the pixel array, the digital controller, and the analog-to-digital converter.

Figure 4: A figure showing parts of a CMOS sensor

• Color filter

The color filter is the same as that described in the CCD-based imager.

• Pixel matrix

As in the case of the CCD, the function of the set of pixels is to capture the intensity of the light that passes through. Each pixel sensor converts the sensitivity of the incoming light into a voltage signal which is then fed to the ADC for further processing.

There are two types of Pixel sensor architectures: Passive Pixel Sensor (PPS) and Active Pixel Sensors (APS).

Figure 5: A diagram showing the passive pixel sensor architecture of pixel sensors

In Passive Pixel sensors only one photodetector (without any local amplifier) per pixel is used whereas in Active Pixel sensors 3-4 transistors per pixel are used.

Figure 6: A diagram showing the active pixel sensor architecture of pixel sensors

Passive pixel sensors have smaller pixels and large fill factor, but are slow and have low SNR. On the other hand, active pixel sensors are fast, have good SNRs, but larger pixels and low fill factor.

However, due to the advancement of CMOS technology down to nm, pixel size/fill factor is no longer a big issue and APS is the preferred technology used in most devices.

• CDA

The ADC takes the analog voltage signals from the pixel sensor array and converts them into a digital signal.

• Digital controller

The digital controller governs the operation of the CMOS sensor; controls the pixel matrix, guarantees synchronism between all pixels, etc.

Operation of CMOS Sensors

Operation of CMOS Sensors

a) The pixel sensor acts as a cargo bucket; accumulates electron charges in the same way that a bucket of water stores water

b) The charge is converted into voltage and amplified in the pixel.

c) Individual CMOS microwires carry voltage one pixel at a time, controlled by the pixel selection switch

d) To output the video signal, follow the following steps

1. All pixel selection switches are ON. This generates the voltage of each pixel in the speaker circuit.

2. Column selection switches turn ON from left to right. In this way, the signal voltages of each pixel on the same line are output in order.

3. This is repeated for all rows, from top to bottom, in order, the signal voltages of all pixels can be output from the upper left corner to the lower right corner of the image sensor.

e) These signal voltages are sent to the camera signal processor.

Fig. 7: A diagram showing the operation of the CMOS sensor

TYPES OF CMOS SENSORS

Difference between types of CMOS sensors is usually due to the number of transistors (affecting the fill factor) present in each pixel. One part of the pixel sensor that is actually sensitive to light is called the fill factor.

a) Type of blind

This has a limited number of transistors and therefore has a high fill factor. However, the rows of pixels are exposed at different times, and therefore movement in the target produces a distorted image.

b) Global shutter type

The number of transistors is high in this case, resulting in a low fill factor. However, all pixels are exposed at once and therefore motion artifacts associated with shutter-type sensors are removed.

CCD and CMOS: pros and cons

CCD AND CMOS SENSORS: PROS AND CONS

1. Manufacturing Process

CCD sensors utilize specialized manufacturing that utilizes dedicated and expensive manufacturing processes, while CMOS sensors rely on standard CMOS technology (used for manufacturing ICs such as microprocessors, memory, etc.). Since CMOS sensors can also integrate the necessary electronic components on the same chip, CMOS sensors result in a compact and cost-effective system

2. Dynamic Range

The dynamic range of the CCD is approximately twice that of the CMOS sensor. This implies that if better color depth is required, CCDs will likely offer better results. On the other hand, CMOS are slightly more photosensitive.

3. Energy consumption

CMOS cameras have lower power consumption than CCDs, but other CMOS circuits may require more power. Low-cost CMOS sensors have low power requirements, but high-speed CMOS cameras typically require more power than CCDs.

4. Noise

Two types of noise affect sensor performance: temporal noise and fixed-pattern noise. Fixed pattern noise is greater in CMOS, compared to CCDs, because the charge is converted to voltage at each pixel, compared to single-point charge-voltage conversion in CCDs. In terms of temporal noise, CMOS sensors are better because the bandwidth of the amplifiers at each pixel is smaller than that of the output amplifier in the case of CCD.

5. Image quality

Due to the low fill factor of CMOS, the photosensitivity of CMOS sensors is low in low light conditions.

6. Uniformity of response

CCDs use a single amplifier for all pixels and CMOS use separate amplifiers for each pixel. Pixel-to-pixel amplification differences lead to non-uniformity. The response of the CCDs is quite uniform.

7. Speed

CMOS sensors have higher speed due to the fact that they use active pixels and ADCs on the same chip, leading to lower propagation delays.

8. Reading area

CMOS sensors allow any region or even multiple regions to be read on the sensor. CCDs are limited by vertical scan reading

9. Smart Functions

With the integration of signal processing circuit into the CMOS sensor chip, functions such as automatic gain control, automatic exposure control, etc., anti-jitter, image compression, color coding, motion tracking, etc.

10. Overexposure effect

Overexposure can cause blurring of overexposed pixels. The smear is caused by charge spillage in the shift register. Due to the absence of shift registers in CMOS sensors, they are immune to this effect.

Multiple CMOS sensors

OTHER CMOS SENSORS

• CMOS humidity and temperature sensors

Switzerland-based Sensirion AG has introduced integrated digital humidity and temperature sensors using CMOS “micromachined” chip technology. SHT11 is a single-chip temperature and relative humidity sensing module with a manufactured calibrated digital output

Figure 8: A representative image of the CMOS humidity and temperature sensor

using CMOS technology.

Conventional humidity sensors determine the relative humidity of the air using capacitive technology. However, they suffer from poor long-term stability and complicated calibration. Furthermore, they require additional circuitry to convert the analog output for interfacing with microprocessors, etc.

The SHT11 uses a micromachined finger electrode system with protective and polymer covering layers forming the capacitance for the sensor chip, while simultaneously protecting the sensor from interference. The sensor chip can be directly connected to any microprocessor system via the 2-wire digital interface.

Because the temperature sensor and humidity sensor are integrated into a single unit, it eliminates measurement errors due to temperature gradients between the two sensing elements. The sensor offers high noise immunity, good stability, short response times, high precision, low power consumption and a small footprint

• 3D image sensor

The DepthSense sensor  is a patented CMOS chip from SoftKinetic DepthSense for 3D imaging. It uses the time-of-flight principle and provides a direct way to acquire 3D information from objects, enabling new applications such as gesture recognition. These sensors are being integrated into cameras.

is a patented CMOS chip from SoftKinetic DepthSense for 3D imaging. It uses the time-of-flight principle and provides a direct way to acquire 3D information from objects, enabling new applications such as gesture recognition. These sensors are being integrated into cameras.

is a patented CMOS chip from SoftKinetic DepthSense for 3D imaging. It uses the time-of-flight principle and provides a direct way to acquire 3D information from objects, enabling new applications such as gesture recognition. These sensors are being integrated into cameras.

is a patented CMOS chip from SoftKinetic DepthSense for 3D imaging. It uses the time-of-flight principle and provides a direct way to acquire 3D information from objects, enabling new applications such as gesture recognition. These sensors are being integrated into cameras. The KODAK 9000 3D Panoramic System is another 3D imaging system for dental applications. With an impressive 3D focused field, it can generate different types of facial images.

• CMOS X-ray detectors

Dexela's flat panel CMOS X-ray detectors are based on innovative crystalline silicon-based CMOS sensor design, offering unprecedented speed and superior image quality. The detectors are suitable for a variety of applications including mammography and tomosynthesis, angiographic imaging, bone densitometry, dental CBCT, scientific instrumentation and NDT.

The main advantages of the technology are: high frame rate, low noise, high reliability, no image delay and high spatial resolution. The clinical benefits are lower radiation dose to the patient combined with superior image quality when compared to flat displays based on amorphous silicon sensor technology. Dexela uses the flexibility, speed and low noise of CMOS technology to create detectors that are flexible, faster, more sensitive, higher resolution and more stable than TFT-based flat panel detectors.

The main components of this detector are: CMOS image sensor, scintillator, control electronics, readout electronics and communication devices.

• CMOS microplates

Cambridge CMOS Sensors provides innovative high-temperature MEMS microchip technology for gas sensing, flow sensing and lab-on-a-chip applications. Technology uses standard CMOS process that enables high-volume, low-cost, low-power sensor-on-a-chip solutions

• CMOS sensor for fluid flow

Burkert Fluid Control Systems uses CMOS technology to measure gas mass flow, measuring the temperature differential.

It uses a Si chip in a location with an exposed diaphragm on the walls of the flow channel. A resistor is connected to the diaphragm; two temperature sensors are installed upstream and downstream of it.

If the heating resistor is supplied with an excitation voltage, the voltage differential from the temperature sensors provides mass flow of the gas flowing through the channel.