In previous projects, adjustable power supply circuits were designed. Sometimes the voltage to drive a specific circuit is already known and the power supply circuit to produce a constant voltage needs to be designed. In this project, a 12V constant power supply circuit is designed for the purpose of powering LED circuits. The circuit needs to be designed in such a way that it is free from any fluctuations or ripples. The circuit will take power from the main AC sources and convert it to a ripple-free 12V DC source. The circuit will be capable of consuming a maximum current of 1A.

In LED circuits, excess current flow through LEDs exceeding their forward current rating can increase their temperature beyond the limit, damaging them permanently or temporarily. Therefore, a constant voltage source is required in such cases. A single LED or a combination of LEDs requiring 12V net input can be connected to the output of the circuit designed in this project.

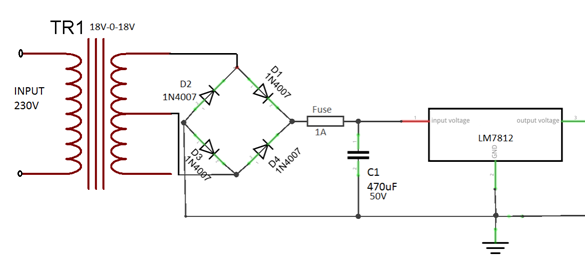

The power circuit designed in this project uses voltage regulator IC 7812 and uses conventional power circuit design steps such as stepping down AC voltage, converting AC voltage to DC voltage, and smoothing DC voltage to obtain direct input from AC grid.

Required components –

Fig. 1: List of components required for constant 12V power supply for LED circuits

Block diagram –

Fig. 2: Block diagram of 12V constant power supply for LED circuits

Circuit Connections –

The circuit is assembled in stages and each stage serves a specific purpose. To step down the 230 V AC, an 18 V – 0 – 18 V transformer is used. The secondary coil of the transformer is connected to a full bridge rectifier. The full bridge rectifier is constructed by connecting four 1N4007 diodes together designated as D1, D2, D3 and D4 in the schematics. The cathode of D1 and the anode of D2 are connected to one of the secondary coils and the cathode of D4 and the anode of D3 are connected to the central ribbon of the secondary coil. The cathodes of D2 and D3 are connected, of which one terminal is taken from the output of the rectifier and the anodes of D1 and D4 are connected, of which another terminal is taken from the output of the full-wave rectifier. A wire is taken from the center strip of the transformer that serves as ground for the positive and negative DC outputs.

A 1A fuse is connected in series to the full wave rectifier output for protection against AC sources. A 470 uF capacitor (shown as C1 in the schematic) is connected across the output terminals of the full-wave rectifier for smoothing purposes. For voltage regulation, IC LM-7812 is connected in parallel with the smoothing capacitor. The output is taken from the voltage output terminal of the 7812 IC.

How the circuit works –

The power circuit operates in well-defined stages, each stage serving a specific purpose. The circuit operates in the following steps –

1. AC to AC Conversion

2. AC to DC Conversion – Full Wave Rectification

3. Smoothing

4. Voltage regulation

AC to AC Conversion

The voltage of the main sources (electricity fed by the intermediate transformer after reducing the line voltage of the generating station) is approximately 220-230 Vac, which still needs to be reduced to the 12 V level. To reduce 220 Vac to 12 Vac, A step-down transformer with center strip is used. The use of the center tap transformer allows generating positive and negative voltages at the input, however, only the positive voltage will be extracted from the transformer. The circuit experiences some drop in output voltage due to resistive loss. Therefore, a transformer with a high voltage rating greater than the required 12V needs to be used. The transformer must provide 1A current at the output. The most suitable step-down transformer that meets the mentioned voltage and current requirements is 18V-0-18V/2A. This transformer reduces the main line voltage to +/- 18 Vac, as shown in the image below.

Fig. 3: 18-0-18V Transformer Circuit Diagram

AC to DC Conversion – Full Wave Rectification

The reduced AC voltage needs to be converted to DC voltage through rectification. Rectification is the process of converting AC voltage to DC voltage. There are two ways to convert an AC signal to DC. One is half-wave rectification and the other is full-wave rectification. In this circuit, a full wave bridge rectifier is used to convert 36V AC to 36V DC. Full-wave rectification is more efficient than half-wave rectification as it provides full use of both the negative and positive sides of the AC signal. In the full-wave bridge rectifier configuration, four diodes are connected in such a way that current flows through them in only one direction, resulting in a DC signal at the output. During full-wave rectification, two diodes are forward biased and two other diodes are reverse biased.

Fig. 4: Full Wave Rectifier Circuit Diagram

During the positive half cycle of the supply, diodes D2 and D4 conduct in series while diodes D1 and D3 are reverse biased and current flows through the output terminal passing through D2, output terminal and D4. During the negative half cycle of the supply, diodes D1 and D3 conduct in series, but diodes D1 and D2 are reverse biased and current flows through D3, output terminal and D1. The direction of current in both directions through the output terminal in both conditions remains the same.

Fig. 5: Circuit Diagram showing the positive cycle of the Full Wave Rectifier

Fig. 6: Circuit diagram showing negative cycle of full wave rectifier

1N4007 diodes are chosen to construct the full wave rectifier because they have the maximum (average) forward current rating of 1A and in reverse bias condition, they can sustain peak reverse voltage up to 1000V. That is why 1N4007 diodes are used in this design for full wave rectification.

Smoothing

Smoothing is the process of smoothing or filtering the DC signal using a capacitor. The output of the full wave rectifier is not a constant DC voltage. The rectifier output has twice the frequency of the main sources, but contains ripples. Therefore, it needs to be smoothed out by connecting a capacitor in parallel to the output of the full-wave rectifier. The capacitor charges and discharges during a cycle, providing a constant DC voltage as output. Thus, a capacitor (shown as C1 in the schematic) of high value is connected to the output of the rectifier circuit. As the DC that has to be rectified by the rectifier circuit has many AC spikes and unwanted ripples, to reduce these spikes a capacitor is used. This capacitor acts as a filtering capacitor that shunts all the AC through it to ground. At the output, the remaining average DC voltage is smoother and ripple-free.

Fig. 7: Smoothing Capacitor Circuit Diagram

Voltage regulation

To provide regulated 12V at the output, an IC LM7812 is used. This IC is capable of delivering current up to 1A. It will provide regulated and stabilized output voltage regardless of variations in input voltage and load current. The IC LM7812 can have input voltages from 14.8V to 27V and provides a constant output voltage of 11.5V to 12.5V. The IC is capable of providing maximum current of 1A at the output.

The LM7812 has the following tolerable power dissipation internally:

Pout = (Maximum IC operating temperature)/ (Thermal Resistance, Junction-Environment + Thermal Resistance, Junction-Enclosure)

Pout = (125) / (65+5) (values according to technical data sheet)

Pout = 1.78W

Therefore, the LM7812 can internally sustain a power dissipation of up to 1.78W. Above 1.78W, the IC will not tolerate the amount of heat generated and will start to burn. This can also cause a serious fire hazard. Therefore, a heat sink is required to dissipate excessive heat from the IC.

Fig. 8: Voltage Regulator Circuit Diagram for 12V Constant Power Supply

Tests and precautions –

The following precautions must be taken while assembling the circuit –

• The rated current of the step-down transformer, bridge diodes and voltage regulator ICs must be greater than or equal to the current required at the output. Otherwise, it will not be able to provide the required current at the output.

• The rated voltage of the step-down transformer must be greater than the maximum required output voltage. This is due to the fact that the IC 7812 experiences voltage drop of around 2 to 3 V. Thus, the input voltage must be 2 V to 3 V greater than the maximum output voltage and must be at the limit of the output voltage. input (14.5V-27V) of the LM7812.

• Capacitors used in the circuit must have a higher voltage rating than the input voltage. Otherwise, the capacitors will start leaking current due to excess voltage on their plates and will explode.

• A capacitor must be used at the output of the rectifier so that it can deal with unwanted noise from the mains. Likewise, the use of a capacitor at the output of the regulator is recommended to deal with rapid transient changes and noise at the output. The value of the output capacitor depends on the voltage deviation, current variations and the transient response time of the capacitor.

• For high output load activation, a heat sink must be mounted in the regulator holes. This will prevent the IC from exploding due to heat dissipation.

• As the regulator IC can only draw current up to 1A, a 1A fuse needs to be connected. This fuse will limit the current in the regulator to 1A. For currents above 1A, the fuse will blow and this will cut off the input power to the circuit. This will protect the circuit and regulator ICs from currents greater than 1A.

Once the circuit is assembled, it can be tested with a multimeter. Measure the output voltage at the terminals of the 7812 IC and start testing it with LED series circuits.

Let's first test the circuit with 1.8V LEDs. A maximum of 6 LEDs of this rating can be connected in series at the output with a 68 ohm limiting resistor. Each LED needs approximately 1.8V to be forward biased and begin to glow. The circuit input voltage is 12V,

Vin = 12V (from 7812)

The total voltage drop across 6 LEDs will be 10.8 V,

V = 1.8 *6 = 10.8 V

The output current supplied by this power supply/Current drawn by the circuit will be –

I = (Input voltage – voltage drop across LEDs) /R1

I = (12 – 10.8)/68

I = 17.6 mA

For a 1.8V LED, approximately 20 mA of forward current is required for adequate illumination without breaking its forward current limit. For this purpose only, a series resistance (in this case 68 ohms) is used to limit the current.

The power dissipation of IC LM7812 with this LED circuit as load will be:

Energy dissipation

P out = (Vin – Vout)*Iout

Pout = (12-10.8) *(0.0176)

Pout = 21.12 mW

Fig. 9: LED Series Circuit Diagram

Testing the circuit with 2.2V LEDs leads to the following results. A maximum of 5 LEDs of this rating can be connected in series at the output with a 47 ohm limiting resistor. Each LED needs approximately 2.2V to be forward biased and begin to glow. The circuit input voltage is 12V,

Vin = 12V (from 7812)

The total voltage drop across 5 LEDs will be 11 V,

V = 2.2 *5 = 11V

The output current supplied by this power supply/Current drawn by the circuit will be –

I = (Input voltage – voltage drop across LEDs) /R1

I = (12 – 11)/47

I = 21.2 mA

For a 2.2V LED, approximately 25 mA of forward current is required for adequate illumination without breaking its forward current limit. For this purpose only, a series resistance (in this case 47 ohms) is used to limit the current.

The power dissipation of IC LM7812 with this LED circuit as load will be:

Energy dissipation

P out = (Vin – Vout)*Iout

Output P = (12-11) *(0.0212)

Output P = 21.2mW

Fig. 10: LED Series Circuit Diagram

Testing the circuit with 3.3V LEDs leads to the following results. A maximum of 3 LEDs of this rating can be connected in series at the output with a 6 or 7 ohm limiting resistor. Each LED needs approximately 3.3V to be forward biased and begin to glow. The circuit input voltage is 12V,

Vin = 12V (from 7812)

The total voltage drop across 3 LEDs will be 10 V,

V = 3.3 *3 = 9.9 V

The output current supplied by this power supply/Current drawn by the circuit will be –

I = (Input voltage – voltage drop across LEDs) /R1

I = (12 – 9.9)/6

I = 350 mA

For a 3.3V LED, approximately 300-350 mA of forward current is required for adequate illumination without breaking its forward current limit. For this purpose only, a series resistance (in this case 6 or 7 ohms) is used to limit the current.

The power dissipation of IC LM7812 with this LED circuit as load will be:

Energy dissipation

P out = (Vin – Vout)*Iout

Output P = (12-9.9) *(0.350)

Output P = 735mW

Fig. 11: LED Series Circuit Diagram

Other LED combinations can also be tested, provided that the correct current limiting resistor is used and considering that the input current requirement of the circuit (LED combination) should not be more than 1A. From the above tests, it can be seen that the power dissipation is always less than 1.78W (tolerable internal limit of 7812). Still, it is recommended to use a heat sink to help cool the IC and increase its useful life.

The power circuit designed in this project can be used to supply power to LED strips and strings. It can also be used to power LED boards. In general, any circuit that requires a constant 12V DC supply with a current limit of 1A can be powered with this power supply unit.

Circuit diagrams

| Circuit Diagram-Constant-12V-Power Supply-LED-Circuits |  |