We have already learned how to work with inductor types and applications. In the previous article, we previously discussed the selection of an inductor for a particular circuit or application. When choosing the right inductor, it is important to know how to read inductor packages. There are many types of inductors in different sizes. Large inductors often have important technical specifications printed on the packaging. Inductors of moderate to small size generally use numerical or color codes to indicate their technical specifications.

Most inductors have their nominal inductance in the Micro-Henry or Milli-Henry range. In addition to the inductance value, tolerance is another important specification marked on most inductor packages. For other specifications, engineers need to consult the data sheets provided by the specific supplier. Inductor packages have the following numerical and color coding systems for indicating nominal value and tolerance –

Numeric encoding

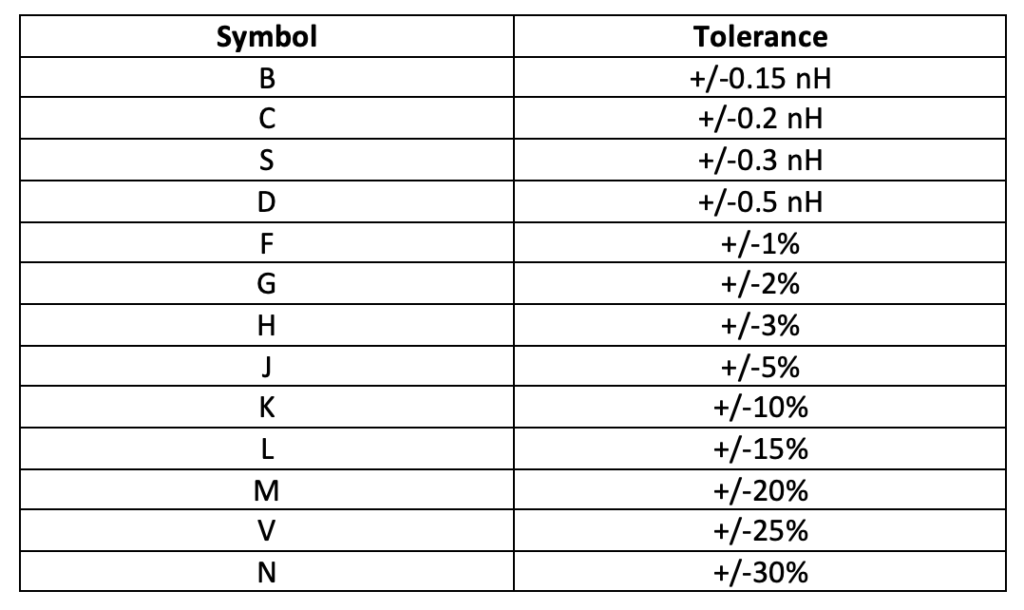

This is the most common type of coding system used by manufacturers. In this system, the inductor value is printed as an alphanumeric code consisting of digits and alphabetical letters. It is a three or four letter code that indicates Micro-Henry inductance. The first two digits indicate the significant digits of the inductance value and the third digit indicates the multiplier. The fourth letter is always an alphabet to indicate tolerance as per the following table:

4-band color coding

For example, if an inductor has a numerical code of 102K printed on it, this implies that it has an inductance of 1000 Micro-Henry or 1 Milli-Henry with a tolerance of 10 percent.

Another popular method used by manufacturers to indicate nominal value and tolerance is color coding. This type of coding system is preferred for inductors that come in axial or radial packaging, such as molded inductors. There may be 4 or 5 band color coding. Color bands are printed near one end of the inductor, from where the bands are read sequentially. In 4-band color codes, the first two bands indicate the significant digits of the inductance value and the third band indicates the multiplier. The inductance value is in Micro-Henry. The fourth band indicates tolerance. The following table can decode a 4-band code:

5-band color coding

For example, if an inductor is color-coded with the first band yellow, the second band violet, the third band brown, and the fourth band black, then the inductor will have a nominal value of 470 uH and a tolerance of 20 percent.

The 5-band color code is used on radial molded inductors used as military radio frequency inductors. On these inductors, the first band is always silver, which indicates that the inductor is for use in military-grade applications. The second and third bands indicate the significant digits of the inductance value and the fourth band indicates the multiplier. The inductance value is in Micro-Henry. The fifth band indicates tolerance. These inductors can have tolerances as low as 1%. The following table can decode a 5-band code:

For example, if a molded inductor has a 5-band color code printed on it, such as the first band is a silver double band, the second band is blue, the third band is green, the fourth band is brown, and the fifth band is red, so it is a military radio frequency inductor with a nominal inductance of 650 Micro-Henry with a tolerance of 2 percent.

Surface Mount Inductor Codes

Surface mount inductors or chip inductors use colored dots instead of colored bands. There are usually three dots that are read clockwise from the top. The first two dots indicate the significant digits of the inductance value and the third dot indicates the multiplier. The inductance value is obtained in Nano Henry. The inductor value is decoded according to the color code of the 4-band system. If there is a single point on a chip inductor, this implies that its datasheet must determine the value and tolerance of the inductor.

RF Inductor Color Codes

RF inductors also have their inductance value indicated by dots. These inductors are similar to SMD inductors but are smaller in size. If there is a single point on the RF inductor, it implies that the inductance and tolerance value can be determined from the inductor data sheet. If there are three dots, two dots will be on one end and one dot will be printed on the other end. The colons are read from top to bottom and indicate significant digits of the inductance value. The single dot at the other end indicates the multiplier. The inductance value is obtained in Nano Henry. Color coding follows the 4-band system coding scheme.

So now you can read the inductance and tolerance of any inductor available in any package. Simply derive the required inductance value and tolerance and choose the correct inductor. Check other specifications in the technical sheets provided by the manufacturer or supplier, if necessary. In the next article, we will discuss transformers.