STEEL IN THE BRAZILIAN INDUSTRY

CNC Machining vs. Manual Machining: A Selection...

Computer numerical control (CNC) and manual machining serve the same purpose. So what's the difference? It's the quality of the final product or the way both work. Although CNC machining...

CNC Machining vs. Manual Machining: A Selection...

Computer numerical control (CNC) and manual machining serve the same purpose. So what's the difference? It's the quality of the final product or the way both work. Although CNC machining...

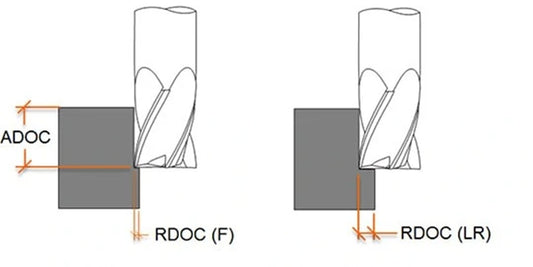

Cutting depth in machining: how to calculate th...

If you choose CNC machining as your part manufacturing method, you should know that depth of cut (DOC) is one of the three most important parameters that affect product quality...

Cutting depth in machining: how to calculate th...

If you choose CNC machining as your part manufacturing method, you should know that depth of cut (DOC) is one of the three most important parameters that affect product quality...

17-4 PH Stainless Steel: A Machining Guide to t...

Stainless steel is a versatile material for CNC machining with diverse applications across a variety of industries. Grade 17-4 PH stainless steel is the preferred stainless steel alloy due to...

17-4 PH Stainless Steel: A Machining Guide to t...

Stainless steel is a versatile material for CNC machining with diverse applications across a variety of industries. Grade 17-4 PH stainless steel is the preferred stainless steel alloy due to...

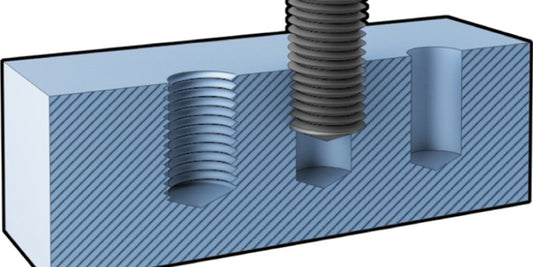

Drilling Threaded Holes: Considerations for Tap...

Thread cutting is one of the most important machining processes. It is used to create screw threads used to fasten materials and components to each other. Tapped holes are widely...

Drilling Threaded Holes: Considerations for Tap...

Thread cutting is one of the most important machining processes. It is used to create screw threads used to fasten materials and components to each other. Tapped holes are widely...

Blind holes in machining: what are they and how...

Product designers and machinists use different types of holes in manufacturing various modern products. Blind holes are often used for machining because they provide ample benefits...

Blind holes in machining: what are they and how...

Product designers and machinists use different types of holes in manufacturing various modern products. Blind holes are often used for machining because they provide ample benefits...

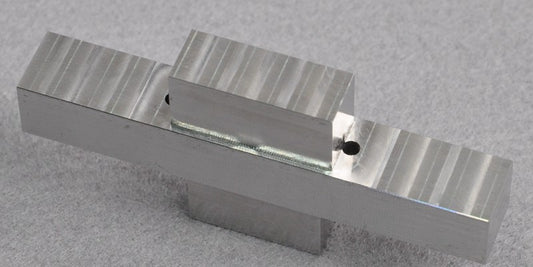

Machine lathe: definition and solutions for cla...

One of the most commonly used clamping tools to hold the part in place is the machine vise. However, you may not know it by the name lathe machine, as...

Machine lathe: definition and solutions for cla...

One of the most commonly used clamping tools to hold the part in place is the machine vise. However, you may not know it by the name lathe machine, as...