STEEL IN THE BRAZILIAN INDUSTRY

Manual arc welding versus CO2 gas protected wel...

The statement that the weld produced by gas shielded welding is not as solid as that of arc welding is not universally true. There are two types of welding wires...

Manual arc welding versus CO2 gas protected wel...

The statement that the weld produced by gas shielded welding is not as solid as that of arc welding is not universally true. There are two types of welding wires...

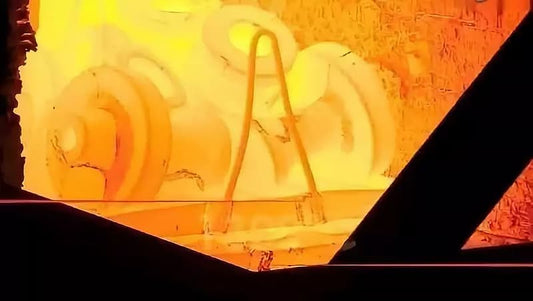

Post-weld heat treatment: pros and cons

Welding residual stress is caused by uneven temperature distribution in the welded parts, thermal expansion and contraction of weld metal, etc., therefore, the associated welding construction...

Post-weld heat treatment: pros and cons

Welding residual stress is caused by uneven temperature distribution in the welded parts, thermal expansion and contraction of weld metal, etc., therefore, the associated welding construction...

Post-Welding Treatment of Aluminum and Aluminum...

I. Residue Removal After welding the workpiece, if gas welding or flux-cored welding rods are used, it is necessary to immediately clean the residual flux and slag from the...

Post-Welding Treatment of Aluminum and Aluminum...

I. Residue Removal After welding the workpiece, if gas welding or flux-cored welding rods are used, it is necessary to immediately clean the residual flux and slag from the...

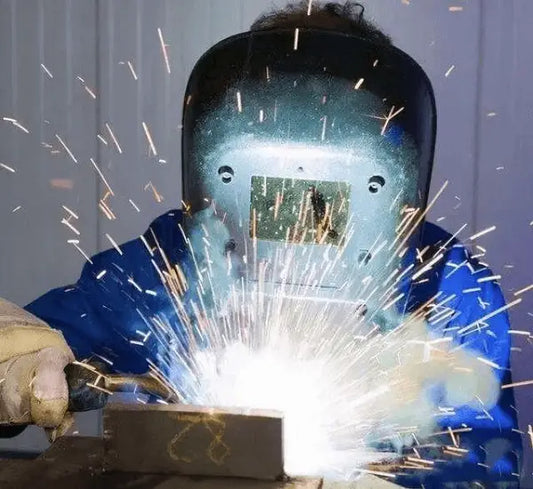

Preventing Risks in Welding: Analysis and Safet...

1. Risk Analysis and Prevention Measures in Welding Operations Welding, also known as arc welding, is a process that uses the thermal effect of welding equipment to heat...

Preventing Risks in Welding: Analysis and Safet...

1. Risk Analysis and Prevention Measures in Welding Operations Welding, also known as arc welding, is a process that uses the thermal effect of welding equipment to heat...

Single-Sided Welding and Double-Sided Forming T...

1. Definition and Classification of Single-Sided Welding and Double-Sided Forming 1.1 Definition of Single-Sided Welding and Double-Sided Forming Single-sided welding and double-sided forming are...

Single-Sided Welding and Double-Sided Forming T...

1. Definition and Classification of Single-Sided Welding and Double-Sided Forming 1.1 Definition of Single-Sided Welding and Double-Sided Forming Single-sided welding and double-sided forming are...

Spray Welding Basics You Should Know

What is spray welding? Spray welding involves heating a preheated self-soluble alloy powder coating to a temperature range of 1000-1300℃, melting the particles...

Spray Welding Basics You Should Know

What is spray welding? Spray welding involves heating a preheated self-soluble alloy powder coating to a temperature range of 1000-1300℃, melting the particles...