It is common knowledge that electricity consumers must pay for the total amount of kilowatt-hours supplied by the electricity concessionaire, measured by the corresponding energy meter. However, because no electrical conductor is perfect and even the highest quality wiring has resistance, some of this electricity is lost between the power meter and the point of use.

What is voltage drop?

One of the basic principles of electrical engineering is Ohm's law, which states that the voltage drop across a conductor or load is equivalent to the product of current and resistance (V = I x R). Electric current is determined by the charge of a circuit, while resistance is determined by the physical properties of the conductor.

Get your voltage drop calculation report from our team of experts in just 5 days.

The concept of voltage drop is used to describe the difference between the voltage supplied at the source and the voltage measured at the load. The factors that determine voltage drop are summarized in the following table:

|

VOLTAGE DROP FACTORS |

DESCRIPTION |

|

A. Conductive material |

Some materials are better electrical conductors than others. For example, copper is more conductive than aluminum. |

|

B. Conductor diameter |

A wider conductor has improved conductivity because there is more material to carry the electrical current. |

|

C. Conductor length |

Longer conductors have greater resistance because the current must travel a greater distance between the source and the load. |

|

D. Conductor temperature |

Temperature influences the conductivity of materials. Depending on the material and the actual temperature, the conductivity may increase or decrease with further increases in temperature. |

|

E. Current carried by the conductor |

The current is directly proportional to the voltage drop. If the current is doubled while the resistance is kept the same, the voltage drop also doubles. |

|

F. Connections in the circuit |

A connection represents an interruption in the conductive material and there is a contact resistance associated with it. Poor connections are associated with greater voltage drop. |

How can voltage drop be controlled?

As there is no perfect conductor and all materials have electrical resistance, it is impossible to completely eliminate voltage drop. However, there are many ways to minimize it:

-

Improving system efficiency

Assuming the load remains the same, increasing the efficiency of electrical equipment reduces energy consumption. Because the supply voltage is constant, the improved efficiency results in less current and reduced voltage drop. -

Problems solution

Some electrical problems cause an unnecessary increase in current or resistance, which leads to a greater voltage drop. Once these problems are resolved, the voltage drop returns to normal. -

Correction of conductor sizes

If the conductors in a circuit are not selected correctly, they can experience a significant voltage drop. When selecting conductors, it is important to take into consideration factors such as full load current, ambient temperature and number of conductors in a raceway. -

Centralized electrical distribution

If the main electrical shaft and switchboards are located near the center of a building, the wiring must travel shorter distances to reach the different loads. This type of layout minimizes voltage drop. On the other hand, when the electrical shaft and panels are located at one end of the building, the circuits must traverse the entire building to reach the loads on the opposite side. -

Balanced load distribution

Large commercial buildings typically use three-phase circuits, which have three energized conductors, as their name implies. If one phase is heavily loaded, it will also experience a higher current and higher voltage drop compared to the other phases.

These are specific measures that can be implemented to reduce voltage drop. In general, any measure that achieves one of the following effects is feasible as long as it is permitted by the New York Electrical Code:

- Decreasing the charging current

- Increasing the conductor diameter

- Increasing the number of parallel conductors

- Decreasing the length of the conductor

- Decreasing conductor temperature

Allowable Voltage Drop Per NEC, 2011 Edition

The NFPA National Electrical Code (NEC), which is the basis of the New York Electrical Code, establishes two conditions for the allowable voltage drop in electrical installations:

- The maximum voltage allowed in a branch circuit is 3%, measured between the corresponding electrical panel and the farthest outlet supplying power, heating, lighting, or any combination of such loads.

- The maximum combined voltage drop across main feeders and branch circuits is 5%, measured from the service connection to the furthest electrical outlet.

These voltage drop levels are considered to provide reasonable operating efficiency. It is important to note that when the size of circuit conductors is increased to compensate for voltage drop, the equipment grounding conductor must be increased accordingly.

How to calculate voltage drop

It is important to note that the voltage drop formula changes depending on the number of phases in the circuit (single-phase or three-phase). In the following equations, the variables used are:

- Z = Conductor impedance (ohms per 1,000 feet or ohms/kft)

- I = Charging current (amps)

- L = Length (feet)

| INSTALLATION TYPE | VOLTAGE DROP FORMULA |

|

Single-phase system Three-phase system |

Drop V = 2 x Z x I x L / 1000 Drop V = 1.73 x Z x IXL / 1000 |

The formulas are divided by 1,000 because standard impedance values are given for every 1,000 feet. This way they are converted to ohms per foot. NEC Chapter 9 provides conductor properties based on a temperature rating of 75°C.

To demonstrate the procedure, assume that a 120-V single-phase circuit carries a current of 22 A, where the conductor impedance is 1.29 ohms per 1,000 feet and the length of the circuit is 50 feet.

- Voltage Drop = (2 x 1.29 ohms / kft x 22A x 50 ft) / 1,000 = 2.84V

- Voltage percentage drop = 2.84 V / 120 V = 0.0237 = 2.37%

If there is more than one conductor per phase, the above calculation must be divided by the number of conductors per phase, as the resistance is reduced. For example, if there are two conductors per phase in the example above, the resistance is halved and the voltage drop would be 1.42V (1.18%).

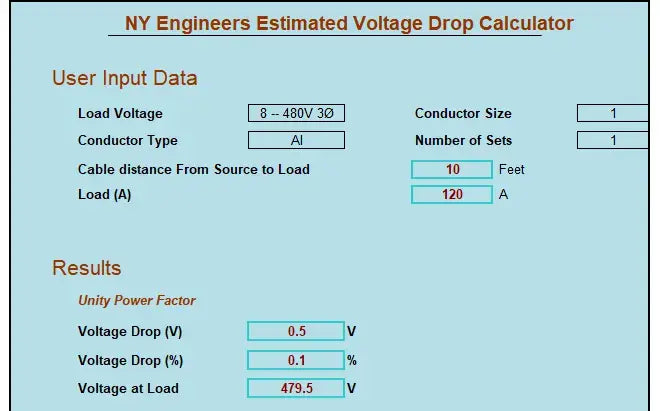

Select the material, copper or aluminum, conductor size, voltage and phase from a list of common voltages, then enter the length of the one-way circuit in feet and the load in amps. This program finds voltage drop, percentage voltage drop, and volts at the end of the circuit.

How to select wire size?

The procedure explained above can be adjusted to select the conductor size based on the allowable voltage drop. Suppose a circuit is subject to the following conditions:

- Operating voltage = 120 V

- Configuration: Single-phase

- Current = 25 A

- Length = 100 feet

The voltage drop formula can be adjusted as follows to calculate the required impedance.

- Voltage drop = 2 x Z x I x L / 1000

- Z = (1000 x Voltage Drop) / (2 x I x L)

Substituting the above values into the formula, the following result is obtained:

- Allowable voltage drop = 120 V x 3% = 3.6 V

- Z = (1000 x 3.6 V) / (2 x 25 A x 100 ft) = 0.72 ohm / kft

According to the NEC in Chapter 9, Table 8, the conductor size required to keep voltage drop below 3% is AWG #6 (0.510 ohm/kft). The following size is AWG #8, but its resistance is very high (0.809 ohm/kft) and the voltage drop would exceed 3%.

Get a professional electrical design for your building and avoid voltage problems.

Installation of multiple conductors in conduit, cable or raceway

NEC Tables 310.16 through 310.19 provide allowable ampacities for a maximum of three conductors in a conduit, cable, or raceway. When the number of conductors is four or more, the allowable ampacity is reduced as shown in the following table:

|

NUMBER OF CURRENT CARRYING CONDUCTORS |

AMPACITY VALUE PERCENTAGE |

|

4-6 7-9 10-20 21-30 31-40 41 or more |

80% 70% 50% 45% 40% 35% |

The conductors must have adequate ampacity for the load according to tables 310.16 to 310.19, in addition to having a voltage drop lower than the maximum allowable value of 3%. Also, note that the ampacity rating is reduced when multiple conductors are installed together. All three factors must be checked to have a code-compliant electrical installation.

Summary

The NEC recommends a maximum voltage drop of 5% on feeders and branch circuits and 3% on the branch circuit only. This level of voltage drop is considered to provide adequate conditions for optimal equipment performance. Note that the maximum allowable voltage drop level is not a safety measure, but a performance measure.