STEEL IN THE BRAZILIAN INDUSTRY

Spray Welding Basics You Should Know

What is spray welding? Spray welding involves heating a preheated self-soluble alloy powder coating to a temperature range of 1000-1300℃, melting the particles...

Spray Welding Basics You Should Know

What is spray welding? Spray welding involves heating a preheated self-soluble alloy powder coating to a temperature range of 1000-1300℃, melting the particles...

Stainless Steel Cold Forming: A Comprehensive G...

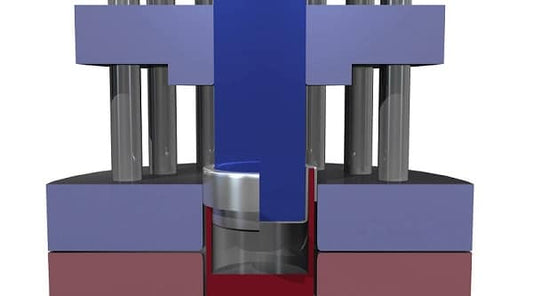

Metal processing can be broadly categorized into two types: cold and hot processing. Hot processing refers to the processing of materials after they are heated, such as...

Stainless Steel Cold Forming: A Comprehensive G...

Metal processing can be broadly categorized into two types: cold and hot processing. Hot processing refers to the processing of materials after they are heated, such as...

Stainless Steel Corrosion Methods and Performan...

1. Brief introduction to the corrosion modes of stainless steel In a wide range of industrial applications, stainless steel offers satisfactory corrosion resistance. Based on experience, the color...

Stainless Steel Corrosion Methods and Performan...

1. Brief introduction to the corrosion modes of stainless steel In a wide range of industrial applications, stainless steel offers satisfactory corrosion resistance. Based on experience, the color...

Electrolytic polishing of stainless steel: expl...

I. Working principle 1. Electrolysis uses the polishing piece as the anode and an insoluble metal as the cathode. When both are immersed in an electrochemical bath and direct current...

Electrolytic polishing of stainless steel: expl...

I. Working principle 1. Electrolysis uses the polishing piece as the anode and an insoluble metal as the cathode. When both are immersed in an electrochemical bath and direct current...

Stainless Steel Mechanical Polishing Technology...

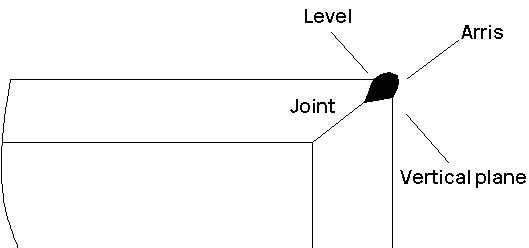

I. Gloss levels after stainless steel polishing Through visual inspection, the surface gloss of a polished part is divided into 5 levels: Level 1: The surface has an oxide film...

Stainless Steel Mechanical Polishing Technology...

I. Gloss levels after stainless steel polishing Through visual inspection, the surface gloss of a polished part is divided into 5 levels: Level 1: The surface has an oxide film...

Stainless Steel Mirror Polishing: Process, Meth...

1. Grinding The main objective of grinding stainless steel weldments is to eliminate welding marks and obtain a surface roughness of R10um on the workpiece in preparation for immersion...

Stainless Steel Mirror Polishing: Process, Meth...

1. Grinding The main objective of grinding stainless steel weldments is to eliminate welding marks and obtain a surface roughness of R10um on the workpiece in preparation for immersion...